Rattan dyeing method for improving dyeing fastness

A dyeing method and dyeing fastness technology, applied in reed/straw treatment, wood treatment, dipping and spraying equipment, etc., can solve the problem of inability to meet the quality requirements of rattan products, achieve good market promotion and application value, and improve dyeing fastness , the effect of superior quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

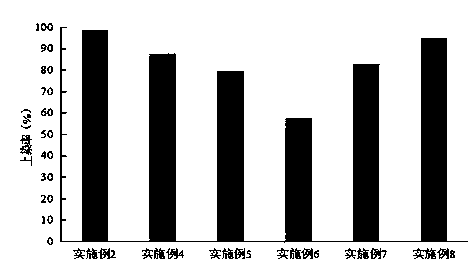

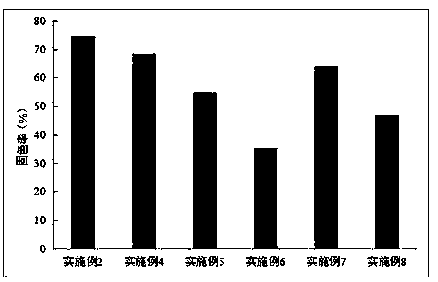

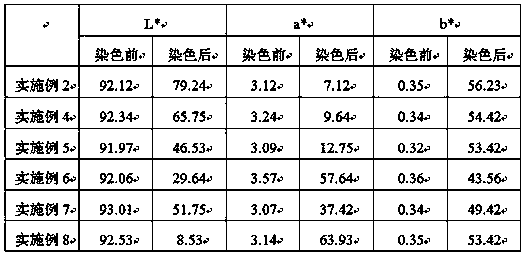

Examples

Embodiment 1

[0049] A kind of rattan dyeing method that improves color fastness, comprises the steps:

[0050] (1) Enzyme solution treatment:

[0051]Immerse the rattan to be dyed in the compound enzyme solution, place it on a shaker, shake and soak at a shaking speed of 80rpm, keep the temperature of the enzyme solution at 37°C during the soaking treatment, filter out the rattan after soaking for 1 hour, and let it dry naturally for later use;

[0052] (2) Cold plasma-microwave treatment:

[0053] Put the rattan treated with the enzyme solution in step (1) in the RF cold plasma treatment equipment, treat it with a treatment power of 180W, control the gas flow rate to 4L / min, and conduct microwave treatment with a treatment power of 300W during the pretreatment. Processing, after processing for 2 minutes, take out the rattan for later use;

[0054] (3) Primary dyeing treatment:

[0055] Spray the dyeing agent evenly on the surface of the rattan treated in step (2), the spraying thicknes...

Embodiment 2

[0063] A kind of rattan dyeing method that improves color fastness, comprises the steps:

[0064] (1) Enzyme solution treatment:

[0065] Immerse the rattan to be dyed in the compound enzyme solution, place it on a shaker, shake and soak at a shaking speed of 90rpm, keep the temperature of the enzyme solution at 39.5°C during the soaking treatment, filter out the rattan after soaking for 1.5h, and let it dry naturally for later use ;

[0066] (2) Cold plasma-microwave treatment:

[0067] Put the rattan treated with the enzyme solution in step (1) in the RF cold plasma treatment equipment, treat it with a treatment power of 210W, control the gas flow rate to 5L / min, and conduct microwave treatment with a treatment power of 350W during the pretreatment Processing, after processing for 2.5 minutes, take out the rattan for later use;

[0068] (3) Primary dyeing treatment:

[0069] Spray the dyeing agent evenly on the surface of the rattan treated in step (2), the thickness of ...

Embodiment 3

[0077] A kind of rattan dyeing method that improves color fastness, comprises the steps:

[0078] (1) Enzyme solution treatment:

[0079] Immerse the rattan to be dyed in the compound enzyme solution, place it on a shaker, shake and soak at a shaking speed of 100rpm, keep the temperature of the enzyme solution at 42°C during the soaking treatment, filter out the rattan after soaking for 2 hours, and let it dry naturally for later use;

[0080] (2) Cold plasma-microwave treatment:

[0081] Put the rattan treated with the enzyme solution in step (1) in the RF cold plasma treatment equipment, treat it with a treatment power of 240W, control the gas flow rate to 6L / min, and conduct microwave treatment with a treatment power of 400W during the pretreatment. Processing, after processing for 3 minutes, take out the rattan for later use;

[0082] (3) Primary dyeing treatment:

[0083] Spray the dyeing agent evenly on the surface of the rattan treated in step (2), the spraying thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com