A single axle rubber wheel bogie

A bogie and rubber wheel technology, applied in the direction of the bogie, the device for the lateral relative movement between the underframe and the bogie, the axle, etc. Anti-overturning function and other issues to achieve the effect of realizing lightweight design, improving anti-overturning ability, and enhancing maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

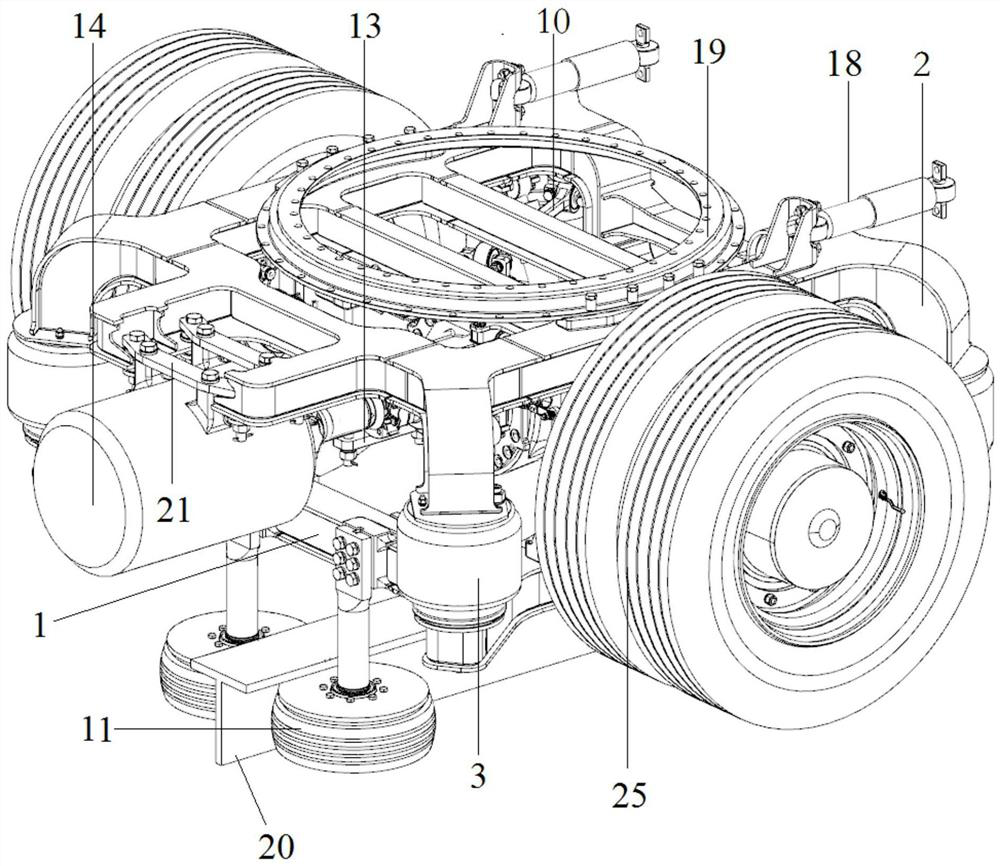

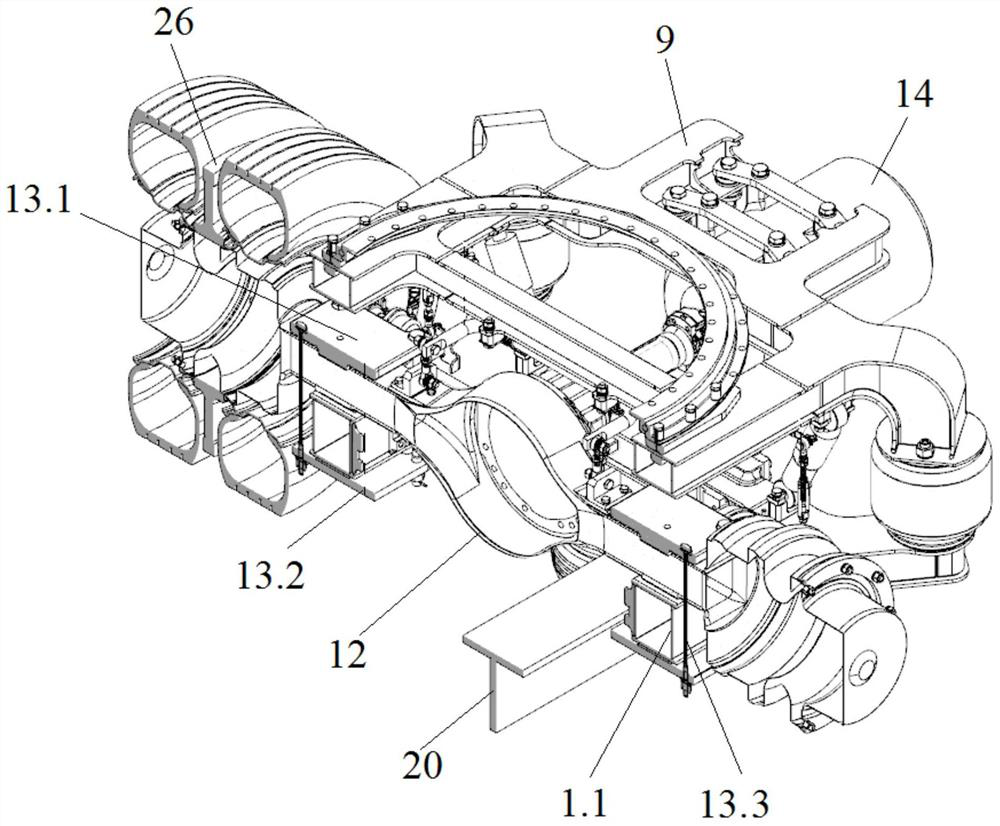

[0041] see Figure 1-11 , a single-axle rubber-tyred light rail vehicle bogie, comprising:

[0042] A frame, the frame includes a guide frame 1 and a suspension 2, the suspension 2 is arranged above the guide frame 1 through at least four air springs (an example of an elastic element), and the guide frame 1 is fixedly provided with a guide wheel 11;

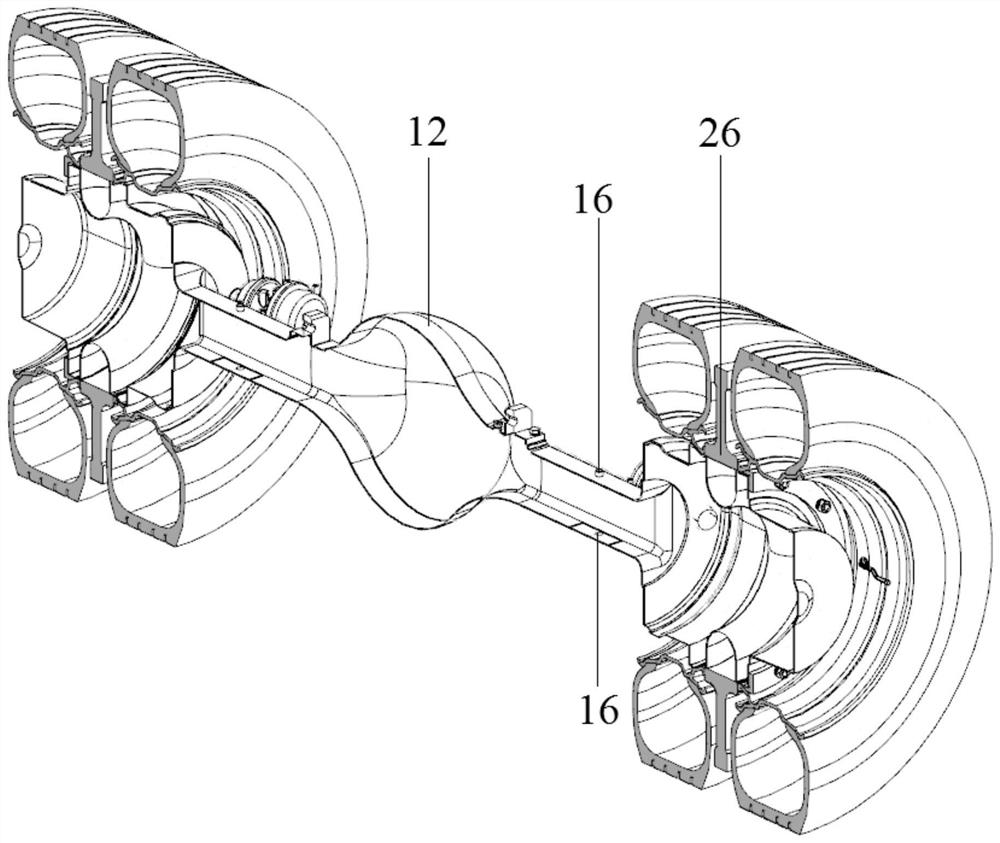

[0043] Axle-bridge device 12, the two ends of the axle-bridge device 12 are provided with rubber wheels 25, and the axle-bridge device 12 is located between the suspension 2 and the guide frame 1, the axle-bridge device 12 adopts the prior art, similar to the automobile rear axle device; as well as

[0044] An axle-bridge fixing device 13, the axle-bridge fixing device 13 is used to fix the axle-bridge device 12 on the guide frame 1;

[0045] Wherein, a drawbar 10 is connected between the axle-bridge fixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com