Automatic programming device for chips

A technology of chips and drive parts, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects, can solve problems such as low work efficiency, space occupation, and waste of resources, and achieve waste of materials, and solve the problem of taking up a lot of space. The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

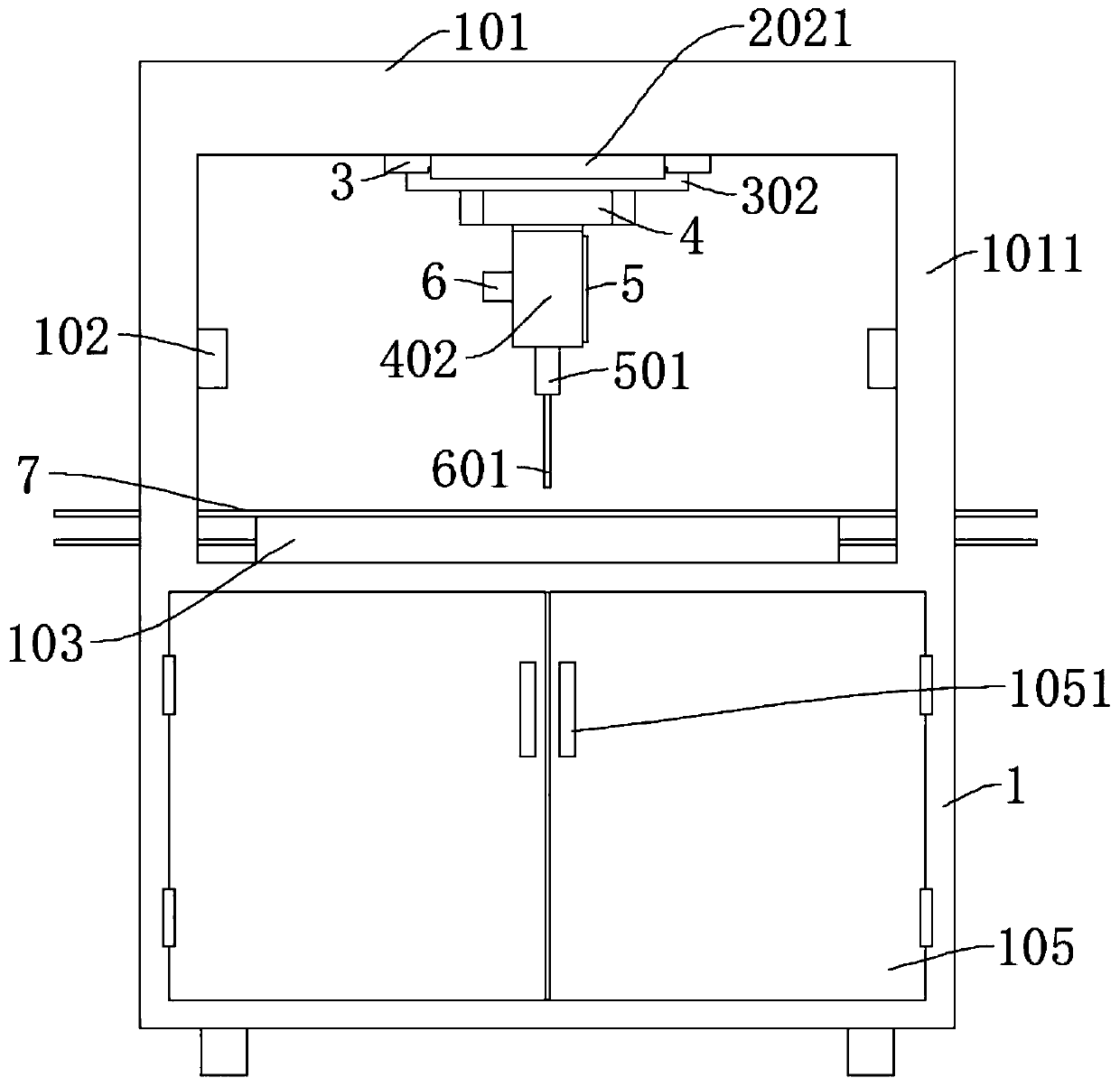

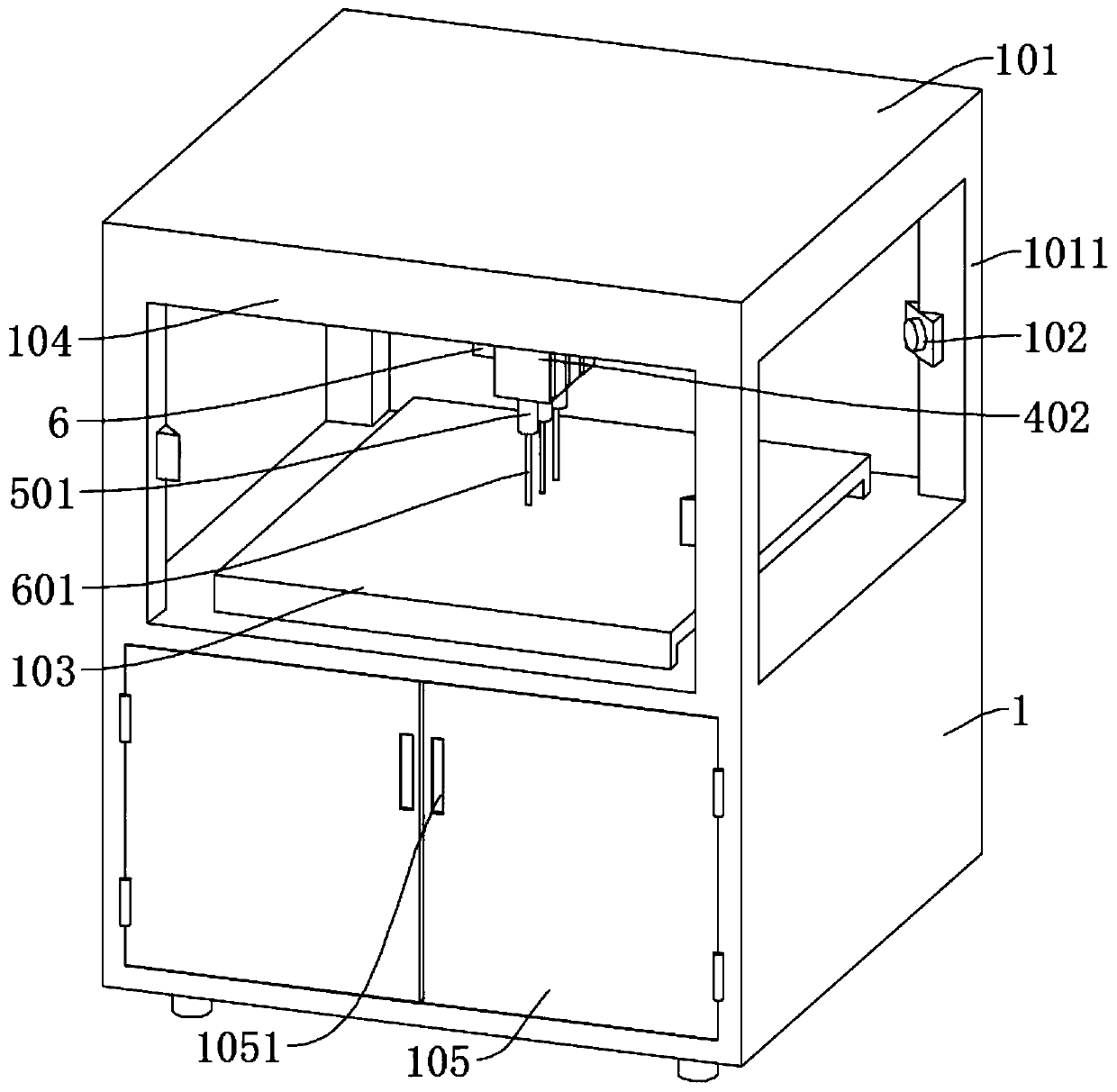

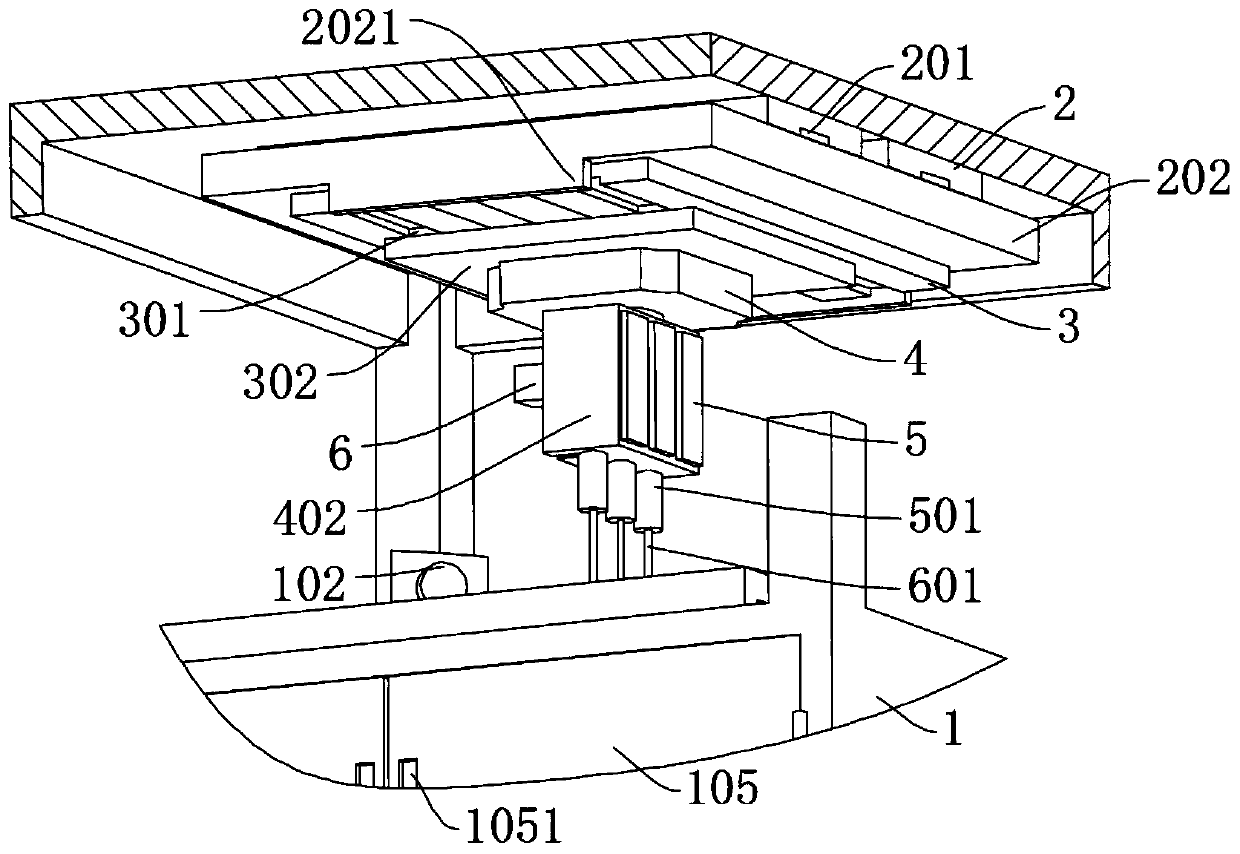

[0026] refer to Figure 1-4 , an automatic chip programming device, including a position sensor 102, a heater 6, a conveyor belt 7, an installation box 1, the top of the installation box 1 is connected to a first workbench 101 through a connecting rod 1011, and the position sensor 102 is connected to the connecting rod 1011, the bottom of the first workbench 101 is slidably connected with the second workbench 202, the bottom of the first workbench 101 is fixedly connected with a transverse driving part for driving the second workbench 202 to move, and the bottom of the second workbench 202 is slidably connected with the second workbench 202. Three workbenches 302, the bottom of the second workbench 202 is fixedly connected with a longitudinal driving part for driving the movement of the third workbench 302, the bottom of the third workbench 302 is rotatably connected with a fourth workbench 402, and the bottom of the third workbench 302 is fixedly connected There is a first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com