Novel module device pipe fitting and manufacturing die thereof

A technology for membrane stacks and pipe fittings, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of increased energy consumption, high cost, complex process, etc., to increase flow rate, reduce pipe loss, wall thick and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

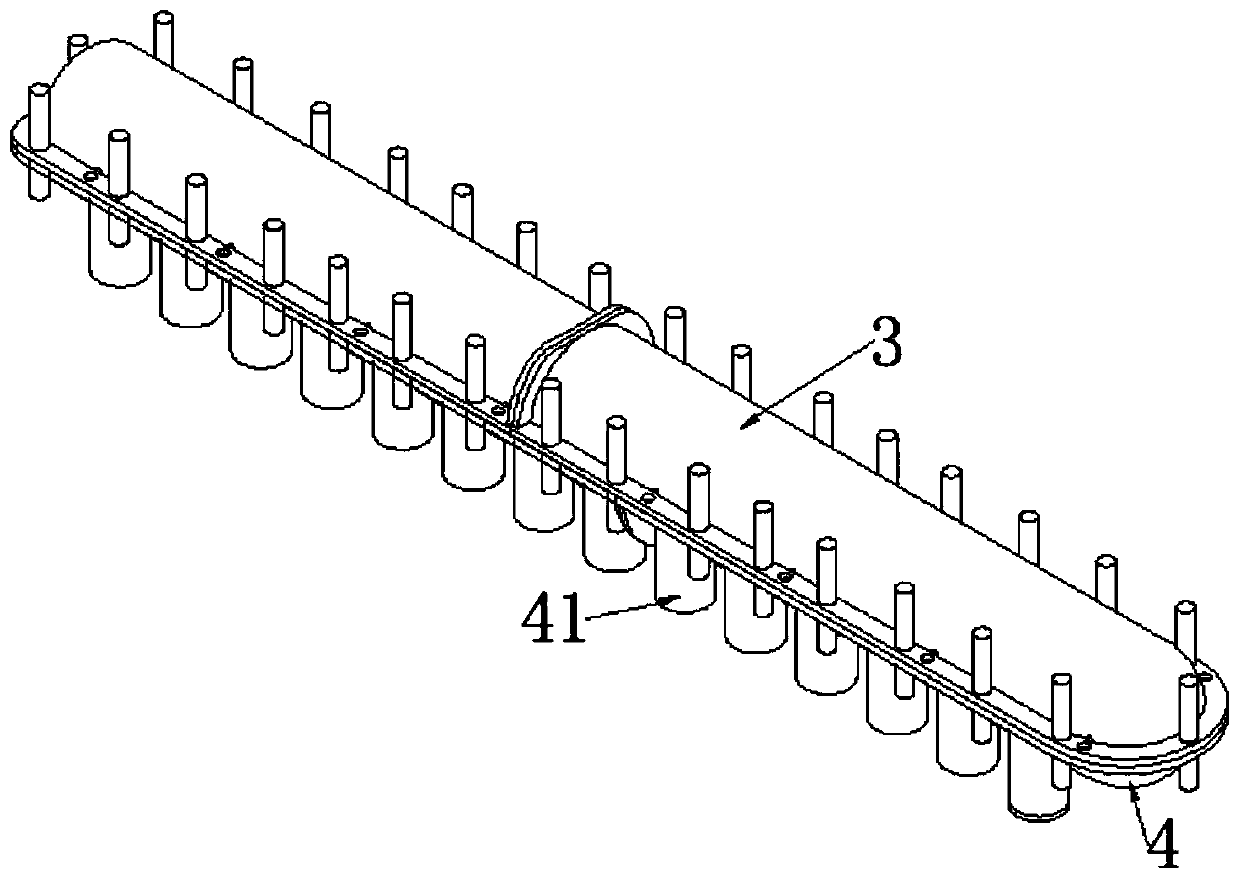

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

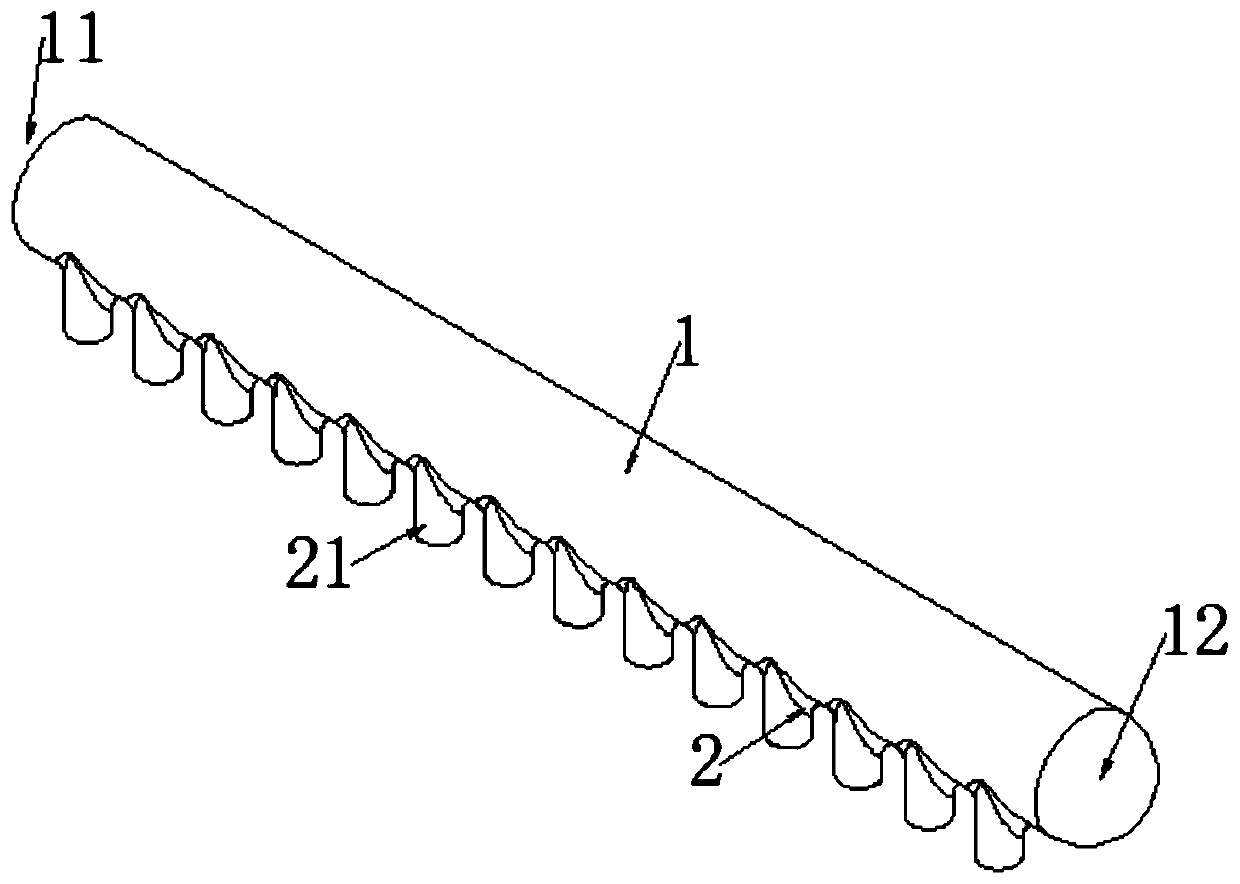

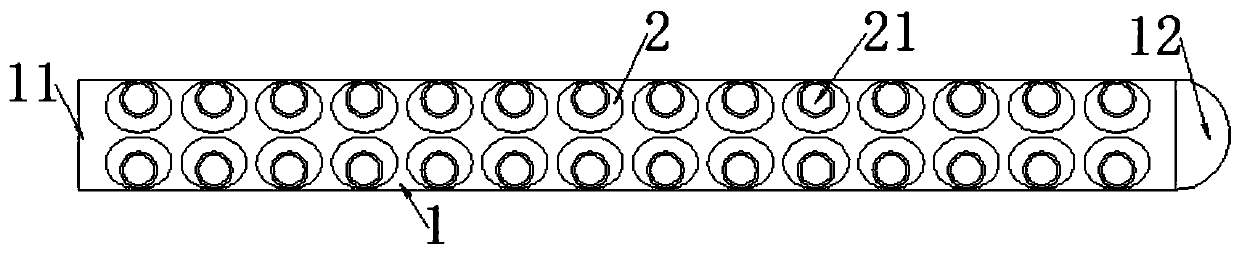

[0022] refer to figure 1 and figure 2 As shown, the present invention provides a novel membrane assembly pipe fitting, comprising a cylindrical main pipe 1, the outer wall of the main pipe 1 is integrally provided with a shunt pipe device 2 along the length direction of the main pipe 1, and the shunt pipe device 2 includes two rows of diversion outlets 21 connected to the main pipeline 1, which are used to communicate with various subsystems of the sewage treatment system. Preferably, the two rows of diversion outlets 21 are distributed in parallel to prevent the separation between the sewage treatment subsystems connected to the diversion outlets. interfere with each other;

[0023] One end of the main pipeline 1 has an outlet 11 connected to the main pipeline of the sewage treatment system, and the other end is provided with an outwardly r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com