Strain-controlled thermal mechanical fatigue performance test method

A technology of thermomechanical fatigue and testing methods, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as large deviations in mechanical deformation, achieve scientific and reasonable test results, and reduce the risk of breaking or bending The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

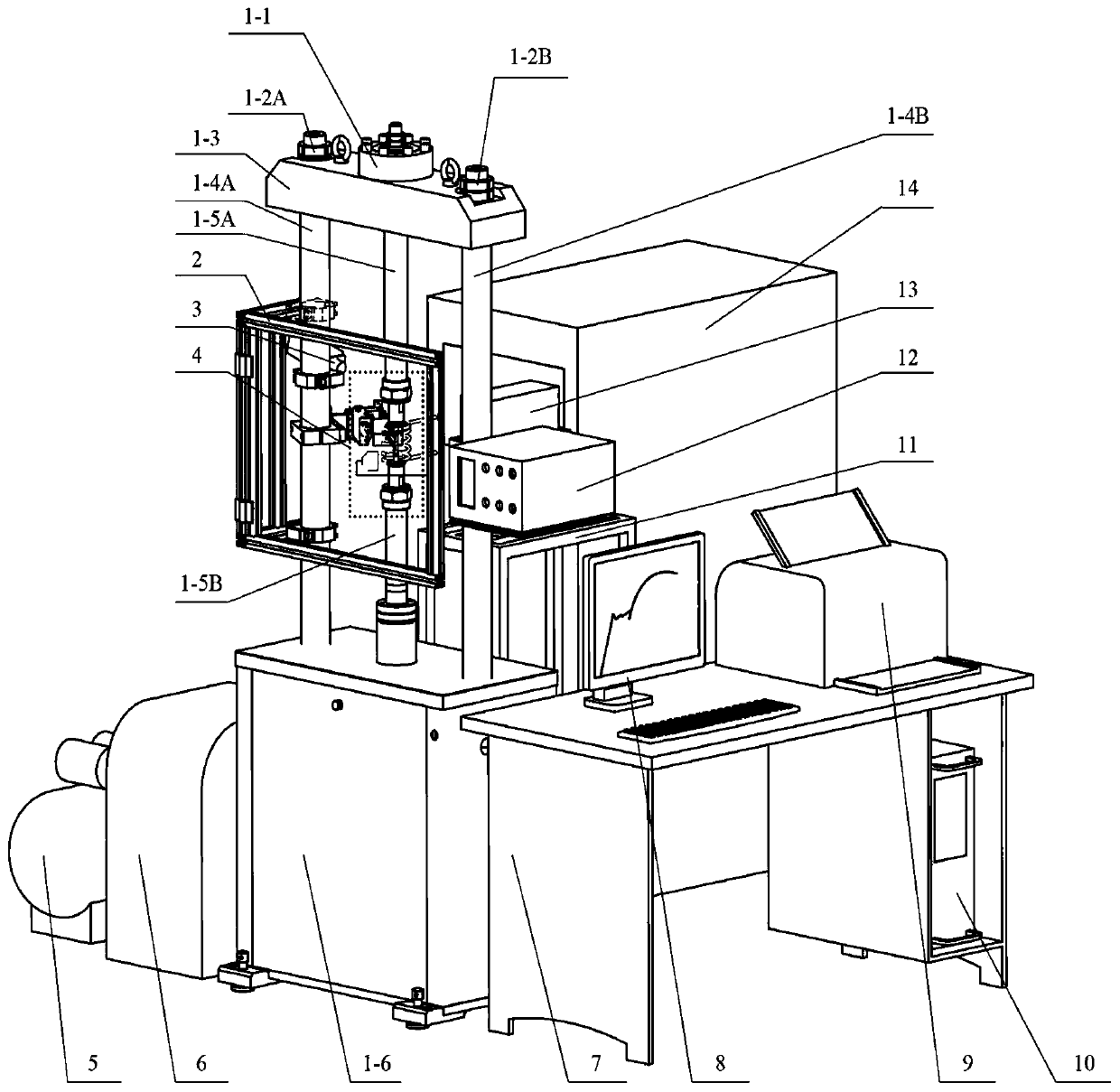

[0046] For the Cr-Mo steel material whose grade is SA387Gr11Cl2, adopt such as figure 1 The thermomechanical fatigue test system shown in the figure carries out the thermomechanical fatigue test in the same phase, the thermal cycle range is 80°C to 490°C, the mechanical strain cycle range is -0.8% to +0.8%, the test period is 410s, and the heating and cooling rate is 2°C / s , the mechanical deformation rate is 1.905um / s.

[0047] The thermomechanical fatigue testing system adopted in the present invention includes a fatigue loading subsystem, a fatigue sample, a heating subsystem, a temperature control subsystem, a strain measurement subsystem, a cooling subsystem and a computer control subsystem.

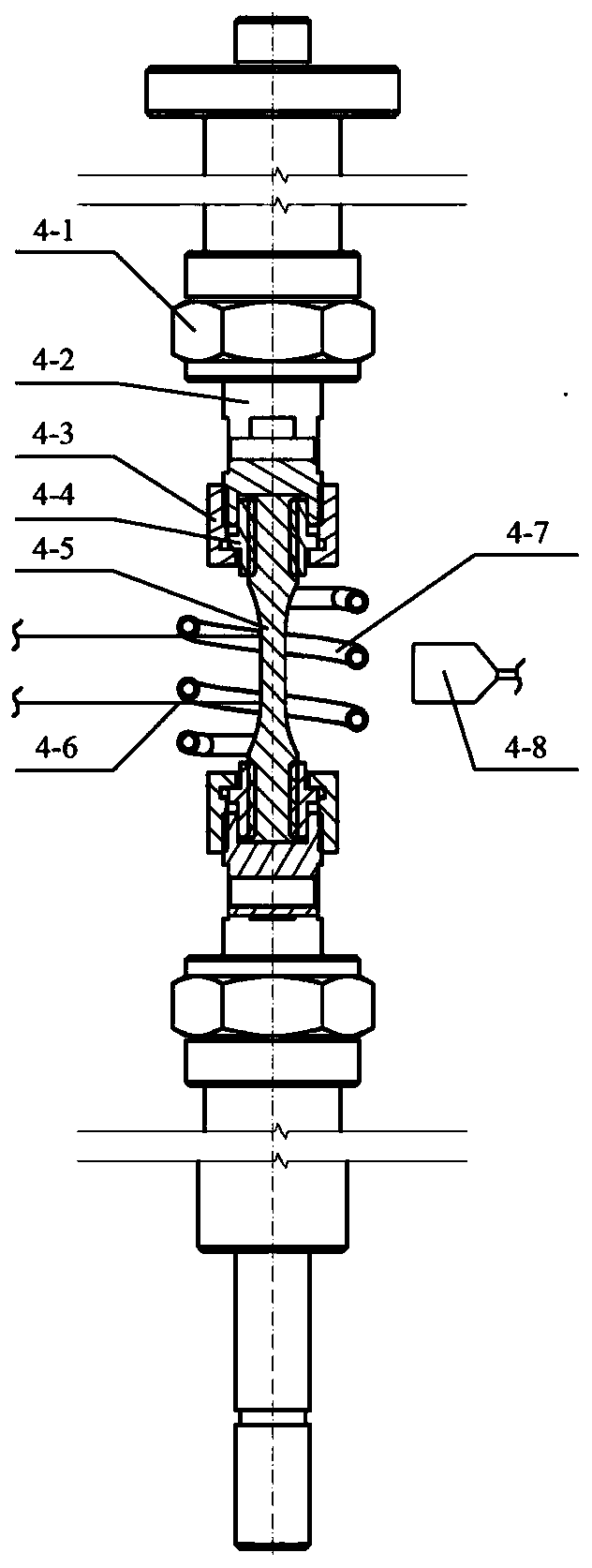

[0048] The fatigue loading subsystem applies the required tensile-compression zero-crossing mechanical load to the fatigue sample stably held by the high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com