Preparation of Pd-Ni catalyst with KMnO4 modified carbon black as carrier

A catalyst and carrier technology, which is applied in the field of improving the performance of direct ethanol fuel cells, can solve problems such as hindering the commercial development of direct alcohol fuel cells, poor anti-poisoning ability, and high price, and achieves production cost reduction, performance improvement, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

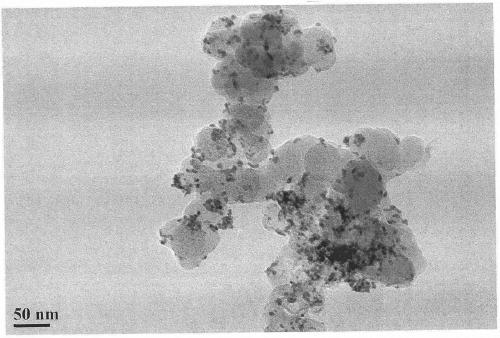

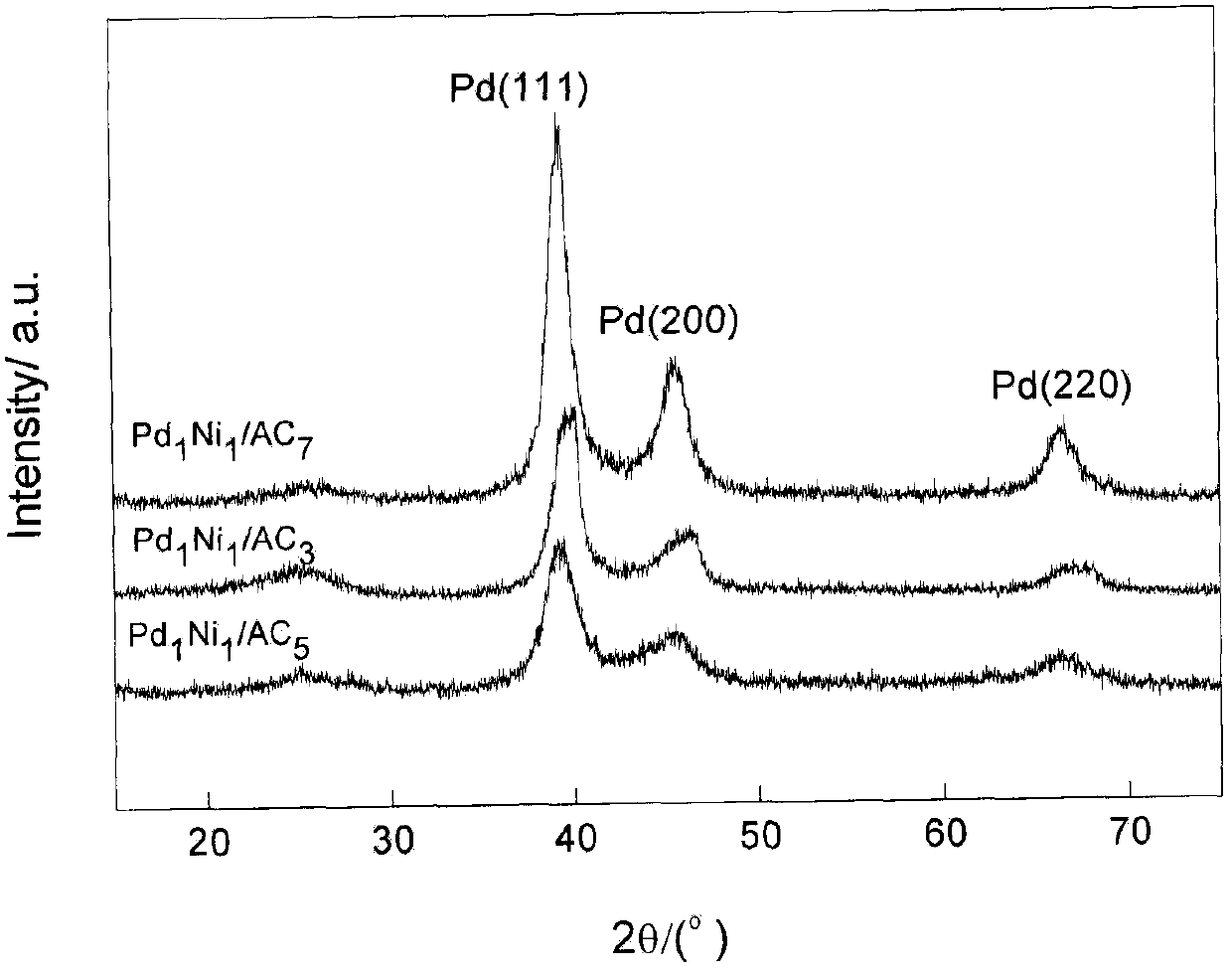

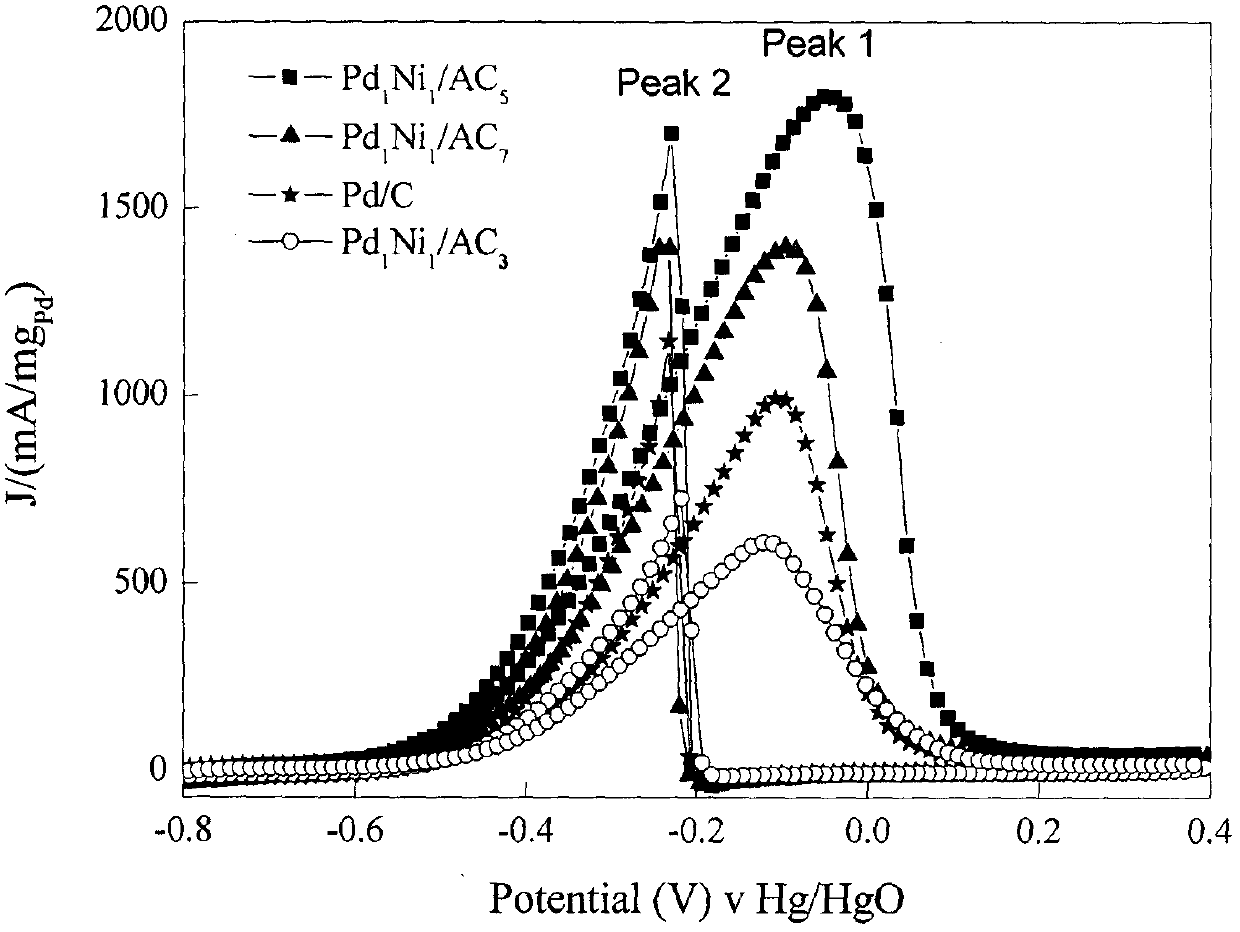

Image

Examples

Embodiment 1

[0017] A kind of direct ethanol fuel cell anode catalyst Pd 1 Ni 1 The preparation method of / AC comprises the steps:

[0018] (1) Mix Vulcan XC-72 carbon black with a certain concentration of KMnO 4 The solutions were blended, stirred for 12 hours, washed with water, and vacuum-dried at 70°C to obtain the modified carbon black carrier AC;

[0019] (2) Ultrasonic dispersion of the modified carbon black obtained in (1) and Virahol is made into a uniform solution A;

[0020] (3) PdCl 2 、NiCl 2 ·6H 2 O, citric acid and isopropanol ultrasonically make orange-yellow precursor solution B;

[0021] (4) Slowly add the precursor solution B to the solution A under constant stirring and stir for a certain period of time, then heat up to 80°C;

[0022] (5) Use a certain concentration of NaOH solution to adjust the pH of the solution to strong alkalinity, and add excess NaBH 4 Dilute the solution and continue to stir. After the temperature of the solution drops to room temperature,...

Embodiment 2

[0024] A kind of direct ethanol fuel cell anode catalyst Pd 1 Ni 1 The preparation method of / AC comprises the steps:

[0025] (1) Mix Vulcan XC-72 carbon black with a certain concentration of KMnO 4 The solutions were blended, stirred for 17 hours, washed with water, and vacuum-dried at 70°C to obtain the modified carbon black carrier AC;

[0026] (2) Ultrasonic dispersion of the modified carbon black obtained in (1) and Virahol is made into a uniform solution A;

[0027] (3) PdCl 2 、NiCl 2 ·6H 2 O, citric acid and isopropanol ultrasonically make orange-yellow precursor solution B;

[0028] (4) Slowly add the precursor solution B to the solution A under constant stirring and stir for a certain period of time, then heat up to 80°C;

[0029] (5) Use a certain concentration of NaOH solution to adjust the pH of the solution to strong alkalinity, and add excess NaBH 4 Dilute the solution and continue to stir. After the temperature of the solution drops to room temperature,...

Embodiment 3

[0031] A kind of direct ethanol fuel cell anode catalyst Pd 1 Ni 1 The preparation method of / AC material comprises the steps:

[0032] (1) Mix Vulcan XC-72 carbon black with a certain concentration of KMnO 4 The solutions were blended, stirred for 24 hours, washed with water, and vacuum-dried at 70°C to obtain the modified carbon black carrier AC;

[0033] (2) Ultrasonic dispersion of the modified carbon black obtained in (1) and Virahol is made into a uniform solution A;

[0034] (3) PdCl 2 、NiCl 2 ·6H 2 O, citric acid and isopropanol ultrasonically make orange-yellow precursor solution B;

[0035] (4) Slowly add the precursor solution B to the solution A under constant stirring and stir for a certain period of time, then heat up to 80°C;

[0036] (5) Use a certain concentration of NaOH solution to adjust the pH of the solution to strong alkalinity, and add excess NaBH 4 Dilute the solution and continue to stir. After the temperature of the solution drops to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com