E-type double-winding stator axial flux motor made of amorphous material

A technology of axial magnetic flux and amorphous materials, applied in the direction of synchronous motors with stationary armatures and rotating magnets, etc., can solve the problems that the power density cannot be further improved, the current density is difficult to increase, and the torque power density is small. Achieve the effects of increasing operational redundancy, good cooling effect, and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

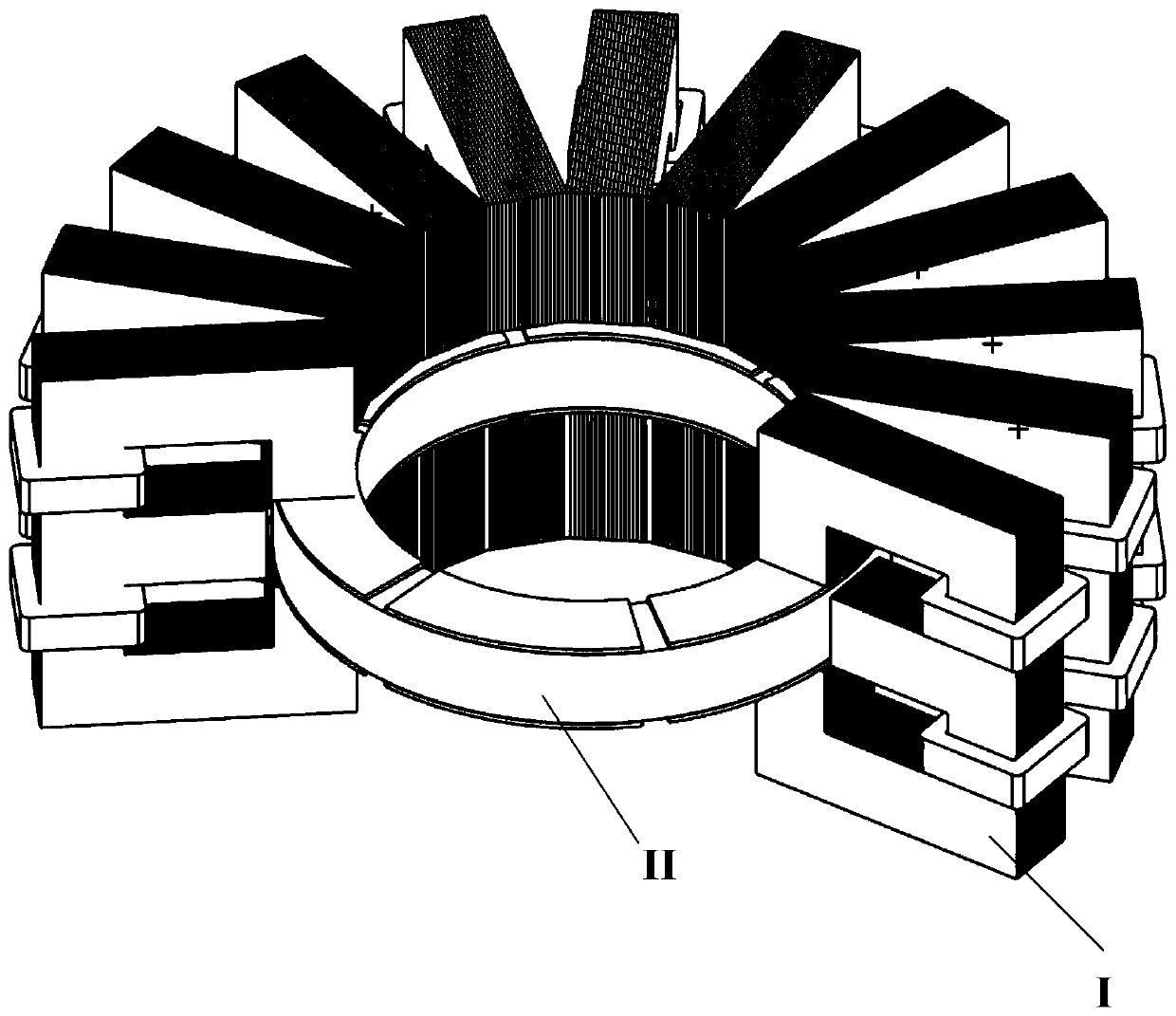

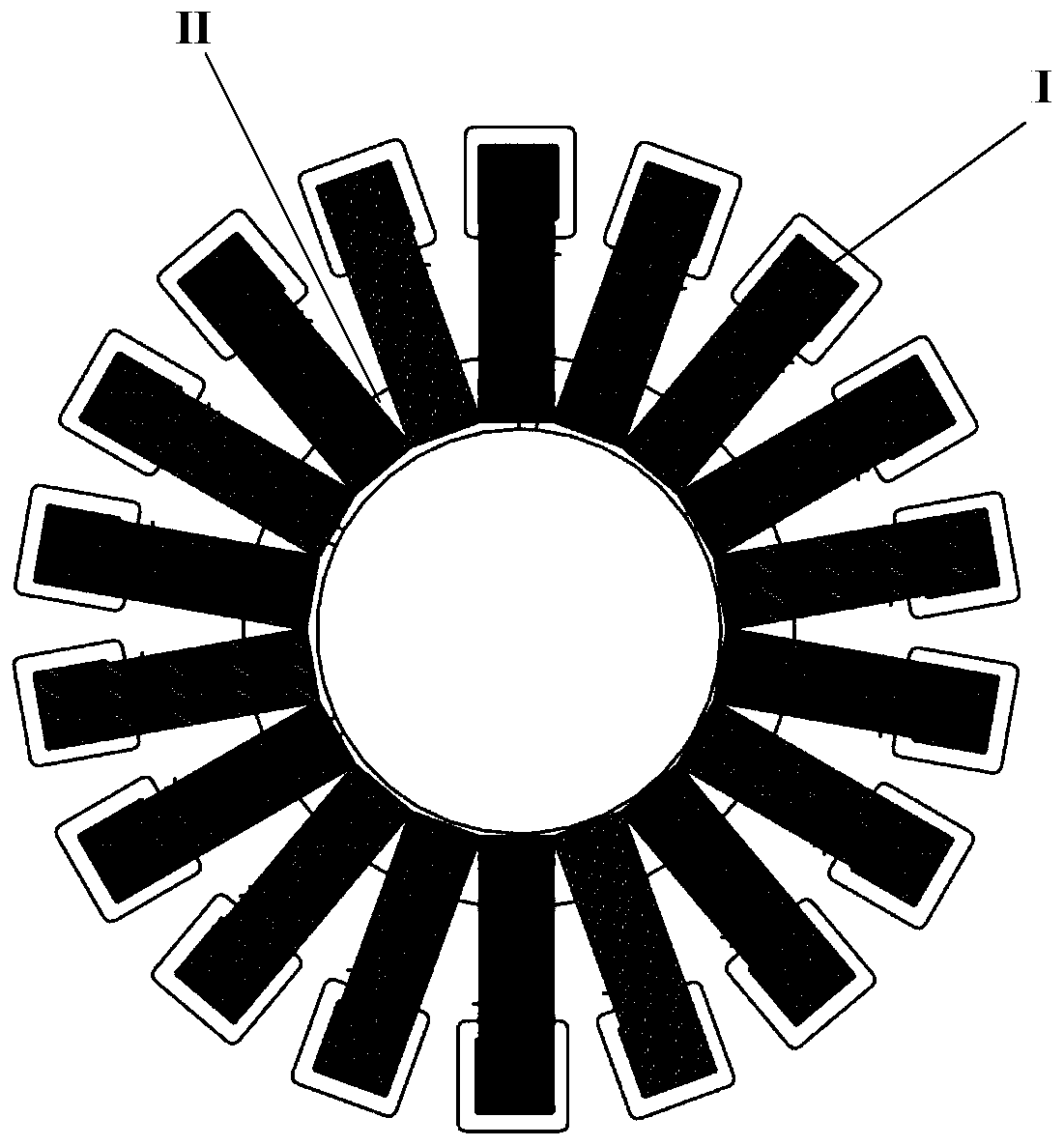

[0022] The E-type double-winding stator axial flux motor of the amorphous material, its specific implementation is as follows figure 1 As shown, it mainly includes two parts: stator assembly part I and rotor part II.

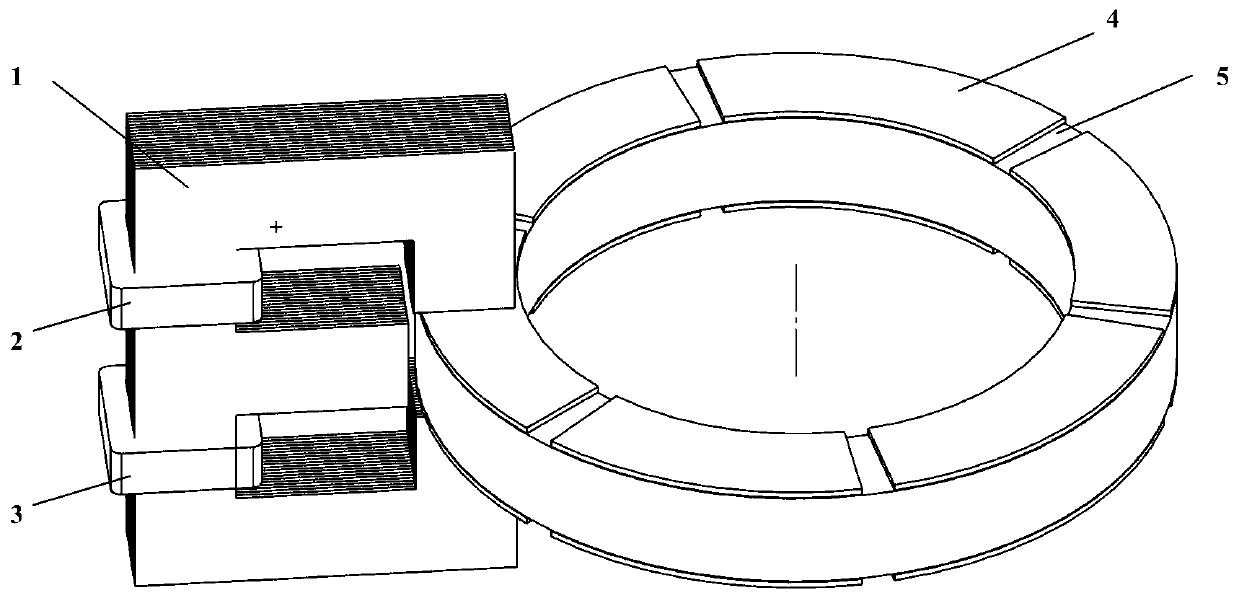

[0023] Stator assembly parts such as image 3 , 4 As shown, the motor includes two parts: the stator combination I located on the outer periphery and the rotor combination II located in the middle; Double winding; stator double winding can use three-phase or multi-phase design, wound on the E-shaped iron core, the rotor combination II includes the rotor core 5 and the rotor permanent magnet 4, the rotor magnet label is attached to the upper and lower sides of the rotor core, It forms a magnetic circuit combination similar to a transformer with the E-type stator core; the stator combination I and the rotor combination II together form a three-phase or multi-phase axial flux permanent magnet synchronous motor.

[0024] Rotor part such as Figure 5 As shown, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com