Planar diaphragm loudspeaker with asynchronous magnetic reflux structure

A technology of planar diaphragm and loudspeaker, applied in the field of loudspeaker, can solve problems such as difficulty in effective reduction, low production capacity and manufacturing efficiency, and poor economy, so as to reduce complex manufacturing process, improve dynamic control ability, and reduce manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The numbers of the upper magnets and the lower magnets are different, and a plurality of upper magnets and a plurality of lower magnets are alternately arranged.

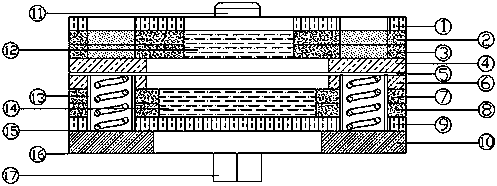

[0079] Such as Figure 1 to Figure 3 , Figure 7 As shown, the symmetrical magnetic circuit structure: the upper magnet and the lower magnet have equal length, equal width and equal height; multiple gaps are formed between adjacent upper magnets, and the lower magnet is arranged facing the gap.

Embodiment 2

[0081] The numbers of the upper magnets and the lower magnets are different, and a plurality of upper magnets and a plurality of lower magnets are alternately arranged.

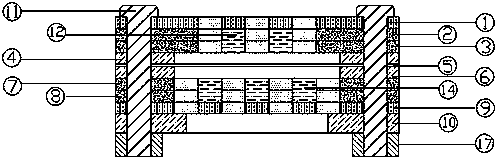

[0082] Symmetrical magnetic circuit structure: the length, width, and height of the upper magnet and the lower magnet are equal; when the number of upper magnets is greater than that of the lower magnets, multiple gaps are formed between adjacent upper magnets, and the lower magnets face the gaps Setting, the relative position of the excess gap formed between the remaining upper magnets is not provided with the lower magnets, and is relatively empty.

Embodiment 3

[0084] The numbers of the upper magnets and the lower magnets are different, and a plurality of upper magnets and a plurality of lower magnets are alternately arranged.

[0085] Symmetrical magnetic circuit structure: the length, width, and height of the upper and lower magnets are equal; when the number of upper and lower magnets is greater than the number of upper magnets, multiple gaps are formed between adjacent lower magnets, and the upper magnet is facing the gap Setting, the relative position of the excess gap formed between the remaining lower magnets is not provided with lower magnets, and is relatively empty.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com