Method and device for preparing oxidized bactericide

A technology for preparing devices and fungicides, applied in the directions of fungicides, chemical instruments and methods, botanical equipment and methods, etc., can solve the problems of insignificant bactericidal effect, poor effect, insufficient mixing of raw materials, etc., and achieve storage time. Long-term, good sterilization effect, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

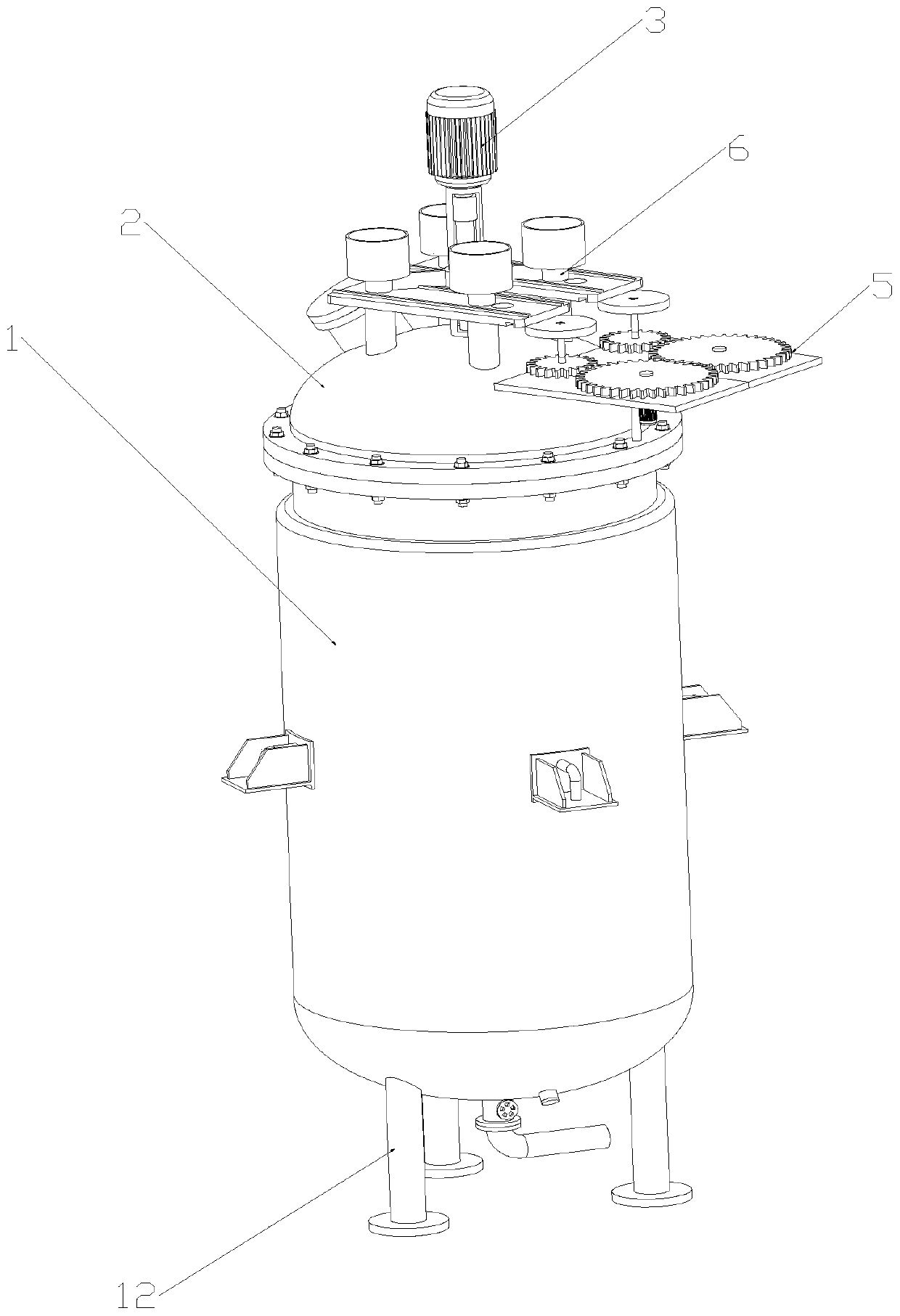

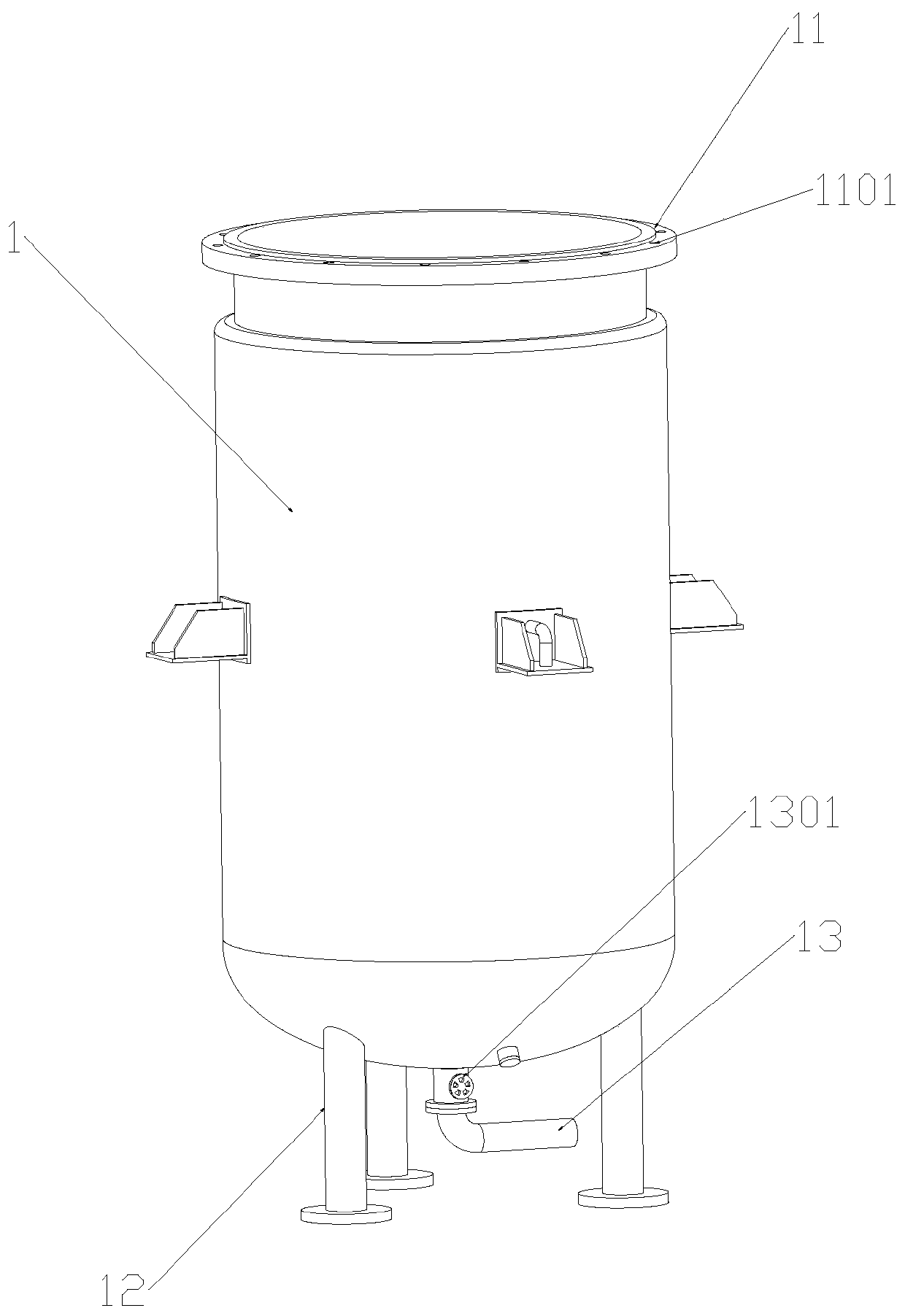

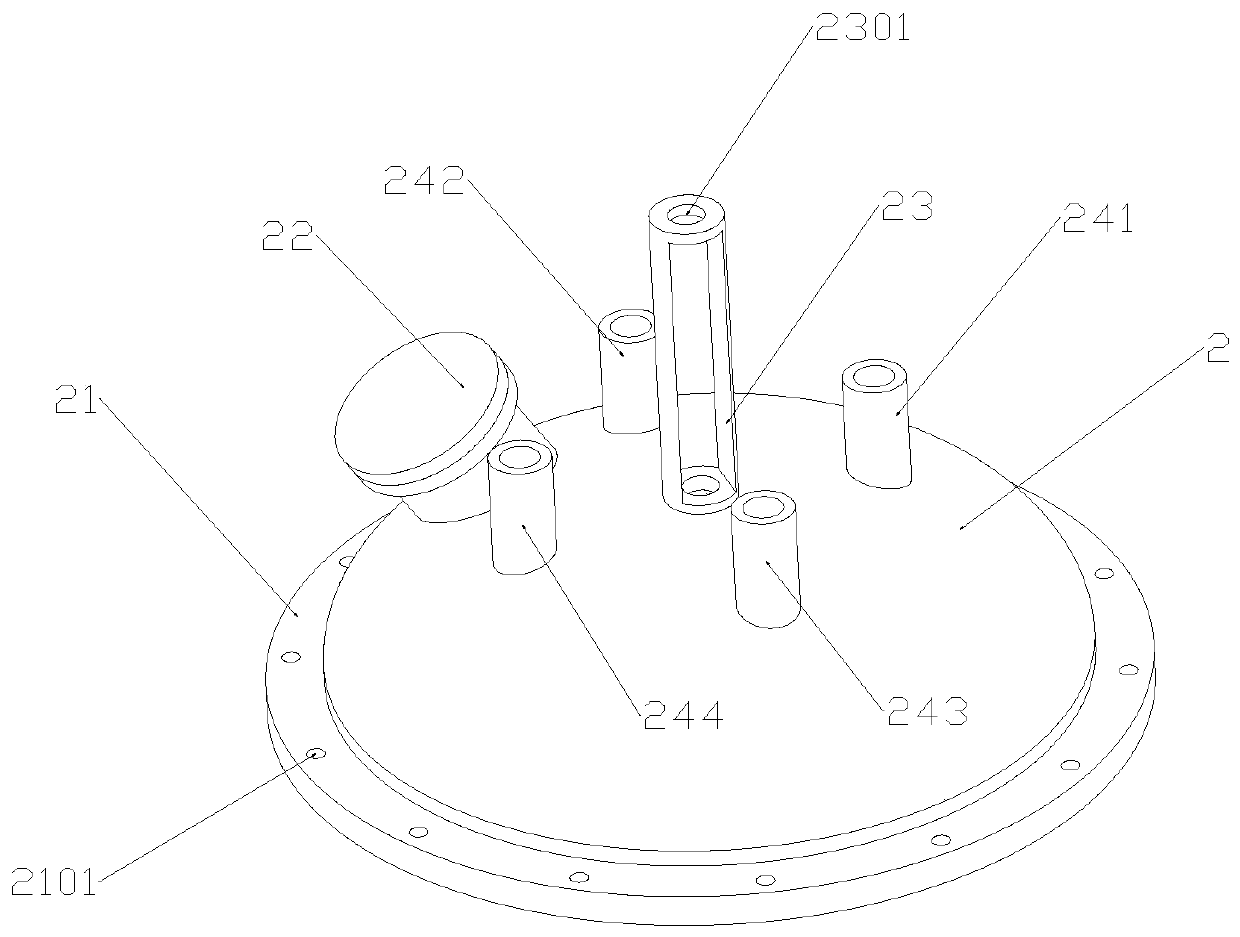

[0049] A preparation method of an oxidizing bactericide, wherein the raw materials used in the preparation of the oxidizing bactericide include deionized water, a gelling agent, a stabilizer, a synergist, a regulator, hydrogen peroxide, and chlorine dioxide.

[0050] Both hydrogen peroxide and chlorine dioxide are liquid, the gel is made of tragacanth gum, the stabilizer is one of organic tin or organic antimony, the synergist is trimethoprim, and the regulator is hydrochloric acid Or a type of nitric acid.

[0051] The ratio of the raw materials by weight is: 100 parts of deionized water, 8-12 parts of gelling agent, 6-8 parts of stabilizer, 11-15 parts of synergist, 4-8 parts of regulator, 25-25 parts of hydrogen peroxide 45 parts, chlorine dioxide 10-15 parts.

Embodiment 1

[0053] 10,000 grams of deionized water, 800 grams of gelling agent, 600 grams of stabilizer, 1,100 grams of synergist, 400 grams of conditioner, 2,500 grams of hydrogen peroxide, and 1,000 grams of chlorine dioxide.

Embodiment 2

[0055] 10,000 grams of deionized water, 1,200 grams of gelling agent, 800 grams of stabilizer, 1,500 grams of synergist, 800 grams of conditioner, 4,500 grams of hydrogen peroxide, and 1,500 grams of chlorine dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com