A high-throughput reactor for catalytic pyrolysis of biomass

A catalytic pyrolysis and fluidized bed reactor technology, which is applied in the preparation of liquid hydrocarbon mixtures, educts, indirect heating and dry distillation, etc., can solve the problem that high-throughput reactors cannot meet the needs of biomass catalytic pyrolysis, and are not designed High-throughput reaction unit and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

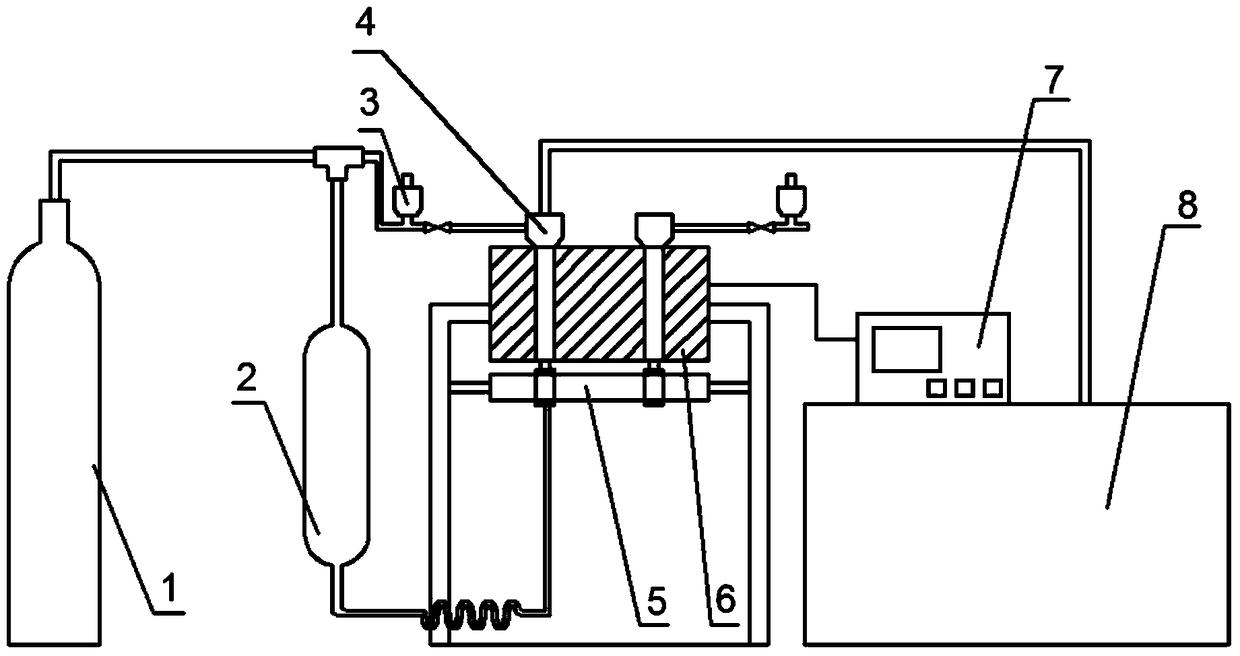

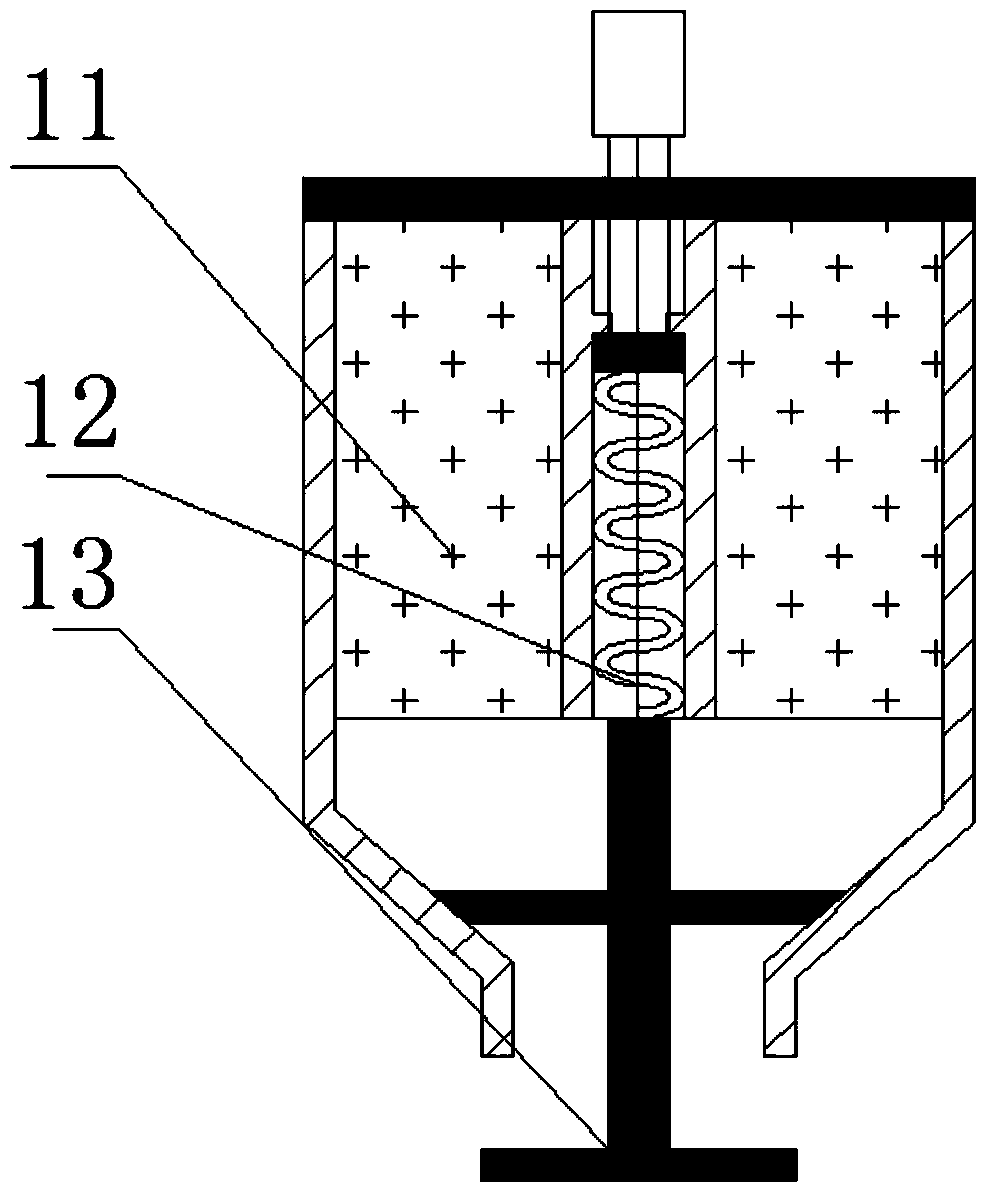

[0032] The high-throughput reactor suitable for catalytic pyrolysis of biomass described in this embodiment is characterized in that: the high-throughput reactor suitable for catalytic pyrolysis of biomass includes a preheating tank 2, a solid powder generator Material feeder 3, fluidized bed reactor 4, multi-channel gas distributor 5, multi-channel heating furnace 6, temperature control system 7, high-resolution flight mass spectrometer 8;

[0033] Among them: the gas source 1 is connected to the preheating tank 2, and the preheating tank 2 is connected to the multi-channel heating furnace 6 through the multi-channel gas distributor 5; the fluidized bed reactor 4 is installed in the multi-channel heating furnace 6; the temperature control system 7 Respectively connected with multi-channel heating furnace 6 and high-resolution flight mass spectrometer 8; solid powder biomass feeder 3 is connected with fluidized bed reactor 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com