Grinding device for art painting paint

A grinding device and painting technology, applied in application, cocoa, grain processing, etc., can solve the problem of long pigment grinding time, and achieve the effect of freely adjusting the speed of the grinding seat, large grinding area, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

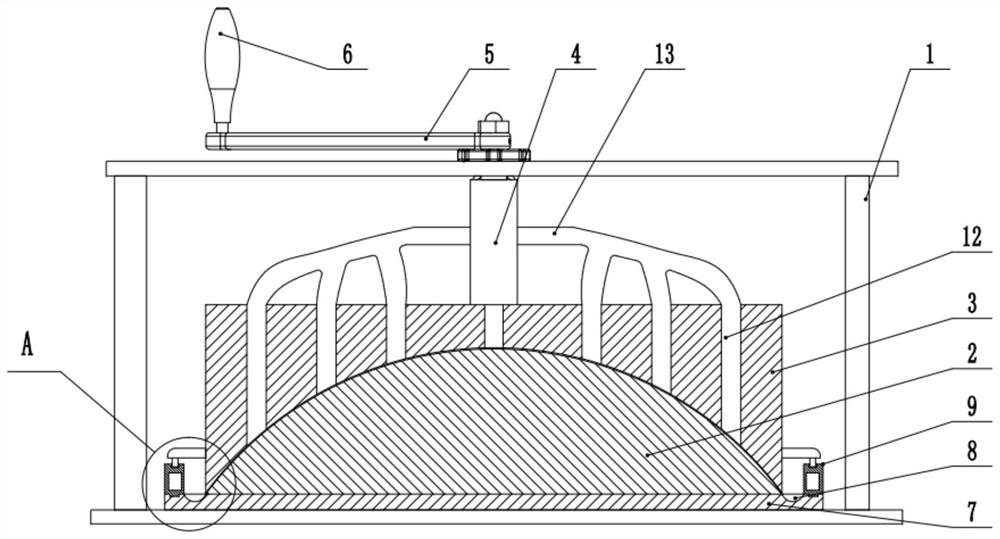

[0032] Basic as attached figure 1 with attached figure 2 Shown: a grinding device for art painting paint, including a bracket 1, on which a grinding seat 2 is welded and fixed. The center of the grinding seat 2 is an upward hemispherical protrusion. The bracket 1 is provided with a grinding cover 3 directly above the grinding seat 2, the bottom surface of the grinding cover 3 is a spherical concave surface sunken inward, and the concave surface completely covers the hemispherical protrusion. The center of the top surface of the grinding cover 3 is upwardly fixedly connected with a shaft 4, the shaft 4 is rotatably connected to the support 1, the top of the shaft 4 is threaded and fixedly connected with a sub-rod 5, and the free end of the sub-rod 5 is welded and fixed with a handle 6.

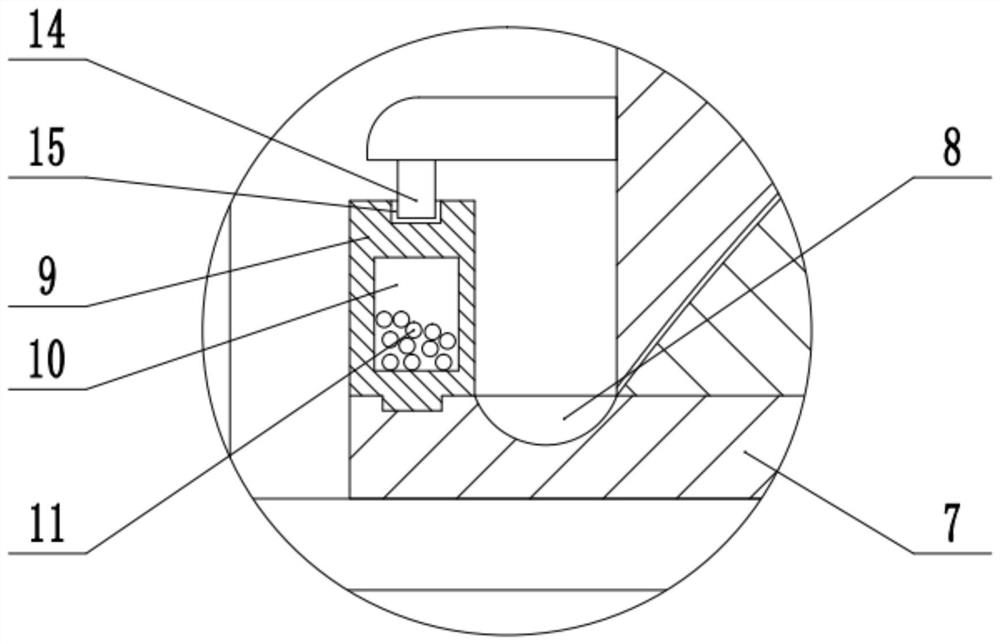

[0033] The bottom of the grinding seat 2 is provided with a base plate 7, and the base plate 7 and the grinding seat 2 are integrally formed. An annular groove 8 is formed on the top of the...

Embodiment 2

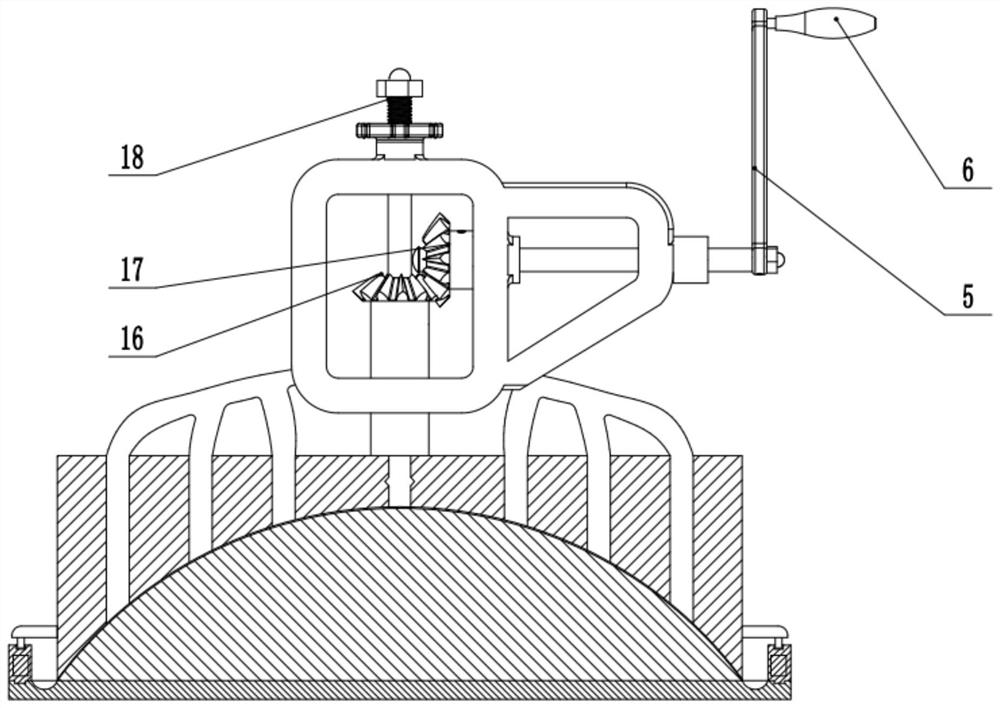

[0038] The difference between this embodiment and Embodiment 1 is that, as attached image 3As shown, the outer wall of the shaft 4 is coaxially fixedly connected with a first bevel gear 16 , one side of the first bevel gear 16 is meshed with a second bevel gear 17 , and the second bevel gear 17 is horizontally connected to the bracket 1 . The right side of the second bevel gear 17 is coaxially fixedly connected to the sub-rod 5 , and the free end of the sub-rod 5 is welded and fixedly connected to the handle 6 . The top end of the shaft rod 4 is screw-connected with an adjustment rod 18 along the axial direction, and the adjustment rod 18 is slidably connected to the support 1 along the vertical direction.

[0039] The specific implementation process is as follows: when the operator needs to rotate the grinding cover 3, he only needs to hold the handle 6 and rotate the handle 6 on the vertical plane. Driven by the handle 6, the sub-rod 5 and the second bevel gear 17 rotate c...

Embodiment 3

[0041] The difference between this embodiment and Embodiment 1 is that, as attached Figure 4 As shown, a servo motor 19 is fixedly connected directly above the shaft rod 4 on the frame, the output shaft of the servo motor 19 is fixedly connected coaxially with the shaft rod 4, and the casing bolts of the servo motor 19 are fixedly connected to the frame. The cavity 10 of each water injection hole 12 is in the shape of an inverted truncated cone, and each water injection hole 12 is provided with a floating block 20 in the shape of an inverted truncated cone. The outer diameter of the bottom surface of the floating block 20 is equal to the minimum inner diameter of the bottom of the water injection hole 12, and the height of the floating block 20 is equal to one-third of the depth of the water injection hole 12. Water injection hole 12 inner walls are fixedly connected with traction rope 21, and the free end of traction rope 21 is fixedly connected on the top surface of floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com