A kind of cleaning equipment and its working method for the processing of cold brewed natural grain powder granules

A technology for cleaning equipment and grains, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient operation, troublesome process, low cleaning efficiency, etc., and achieve the convenience of fixed installation and rotation The effect of stable process and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

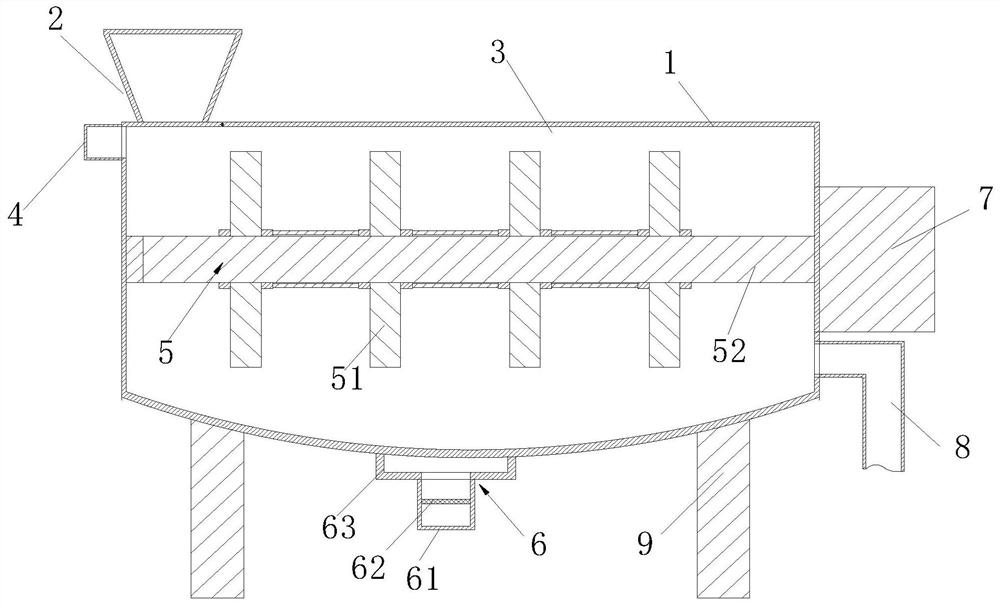

[0035] A cleaning device for processing cold-blended natural grain powder granules, comprising a casing 1, a feeding hopper 2 is arranged on the top of the casing 1, a cleaning chamber 3 is arranged inside the machine, and a rotating connection is arranged on the top of the casing 1 The top cover, the side wall of the casing 1 is provided with an overflow port 4, the side wall of the casing 1 is provided with a motor 7, the motor 7 is connected to the power supply, and the bottom of the motor 7 is provided with a water inlet pipe 8, and the water inlet pipe 8 and the machine The cleaning chamber 3 inside the shell 1 is connected, the bottom of the shell 1 is equipped with a discharge mechanism 6, the bottom of the shell 1 is provided with a foot 9, and the inside of the shell 1 is provided with a stirring mechanism 5; the feed hopper 2 provided can It is convenient to feed the grains. By setting the rotating top cover, the top of the casing 1 can be opened, which facilitates th...

Embodiment 2

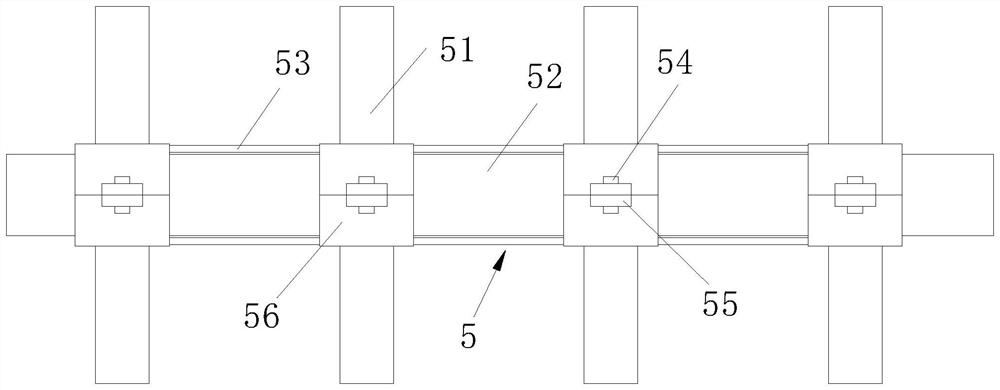

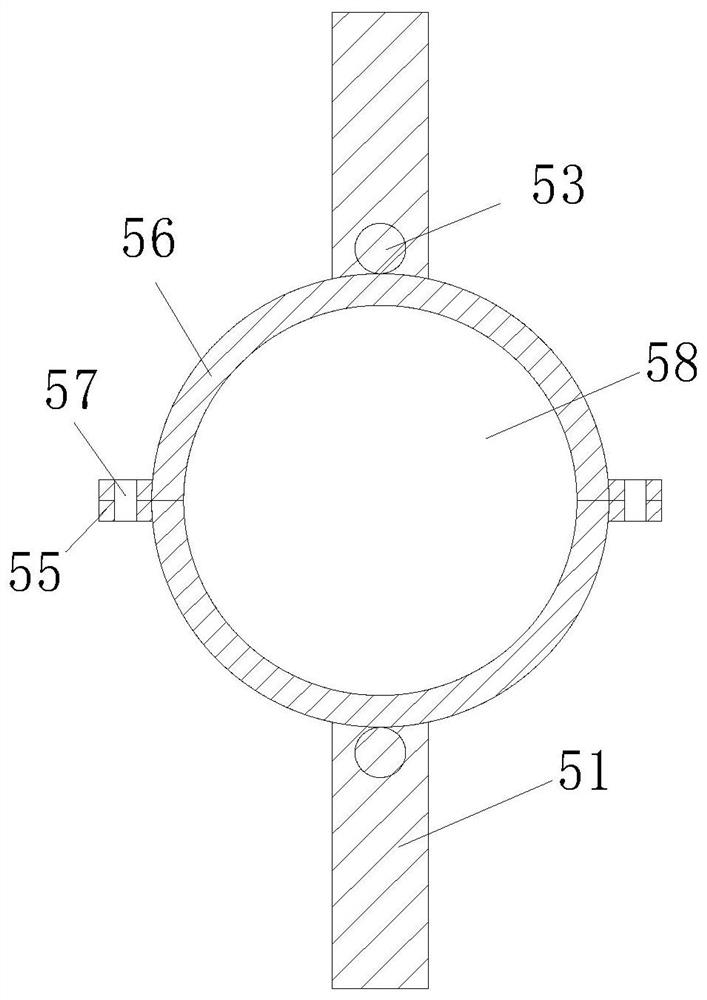

[0040] Specifically, the stirring mechanism 5 includes a drive shaft 52 connected to the motor 7, an annular sleeve 56 is mounted and fixed on the surface of the drive shaft 52, a push plate 510 is arranged on the surface of the ring sleeve 56, and several uniformly distributed The through hole 511 of the push plate 510 is fixed with two connecting plates 59 parallel to each other, and the surface of the connecting plate 59 is provided with several honeycomb holes 512, and the grain with a smaller diameter can be cleaned by the agitating mechanism 5 provided. , the through hole 511 can allow water to filter from the surface of the push plate 510, and when the grain is stirred, the grain will not enter the inside of the through hole 511, so that the grain can be fully stirred, and the connecting plate 59 provided can not only play a large area The smaller grains of the pushing diameter can also play the function of stabilizing the push plate 510, and the honeycomb holes 512 arra...

Embodiment 3

[0045] First close the feeding pipe 61 at the bottom of the discharging mechanism 6, pump water to the water inlet pipe 8 through the water pump, so that the internal water volume of the casing 1 overflows the top of the transmission shaft 52, and the grains with a diameter of 5-8mm that need to be cleaned Drop into the inside of the cleaning chamber 3 from the feed hopper 2 for cleaning. After the grain enters the inside of the cleaning chamber 3, the motor 7 rotates to drive the transmission shaft 52 to rotate, and the transmission shaft 52 can drive the stirring rod 51 to rotate, and the rotation of the stirring rod 51 can Drive the water inside the cleaning chamber 3 to rotate, and the water inside the cleaning chamber 3 can clean the surface of the grain when the grain rotates. When the cleaning process is opened, the feeding pipe 61 is opened so that the cleaning sewage can be filtered and discharged from the filter screen 62. While the stirring rod 51 is stirring, the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com