Electromagnetic pulse forming device and method for bimetallic composite pipe fitting

A technology of bimetal composite pipe and electromagnetic pulse, which is applied in the field of plastic forming of materials, can solve problems such as cracking and poor bonding strength of the interface of composite pipe fittings, and achieve the effect of efficient forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

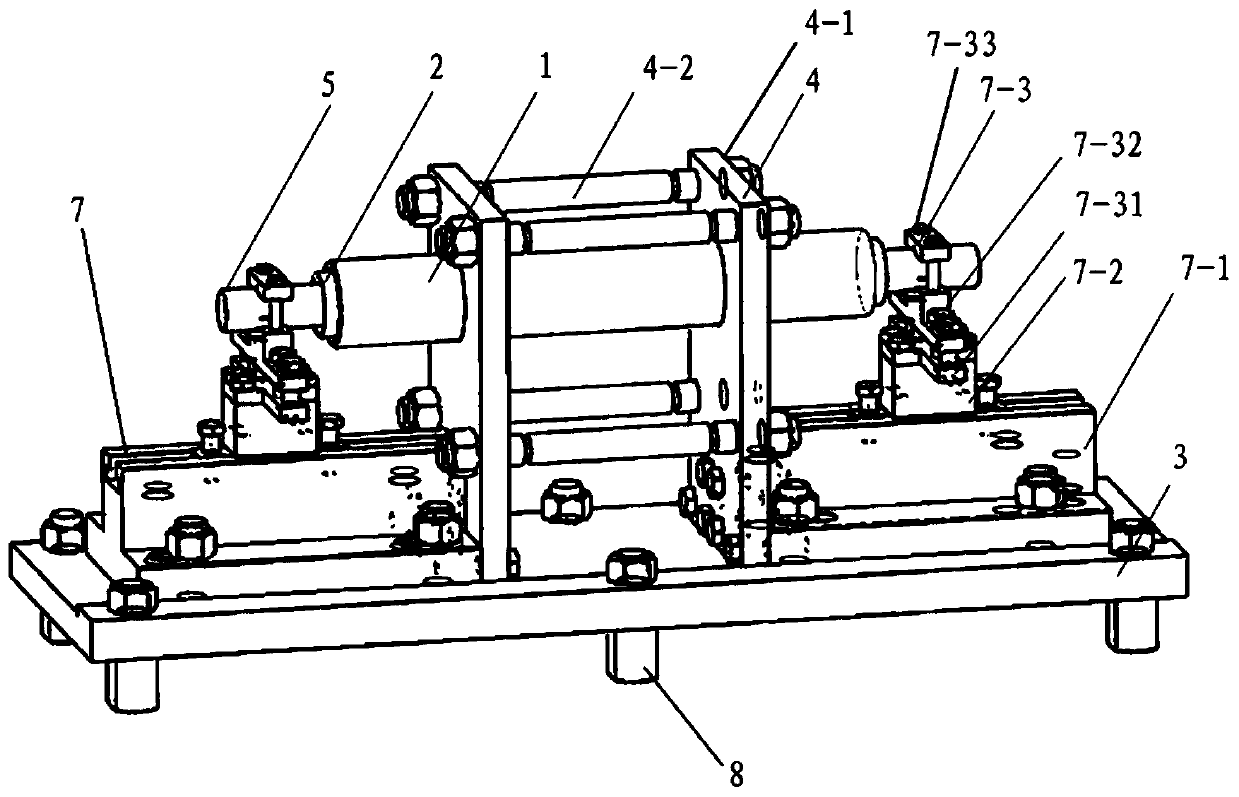

[0022] see Figure 1-3 , an electromagnetic pulse forming device for a bimetallic composite pipe provided in an embodiment of the present invention, the bimetallic composite pipe includes: a first metal sleeve 1 and a second metal sleeve 2, the second metal sleeve 2 is arranged on the first metal Inside the casing 1 , the electromagnetic pulse forming device for bimetallic composite pipe fittings includes: a base 3 , a supporting component 4 , an insulating rod 5 , a coil 6 and two sliding mechanisms 7 .

[0023] Two sliding mechanisms 7 are oppositely arranged on the base 3 .

[0024] The middle part of the insulating rod 5 is slidably arranged in the second metal sleeve 2 .

[0025] The coil 6 is fixedly arranged on the insulating rod 5 .

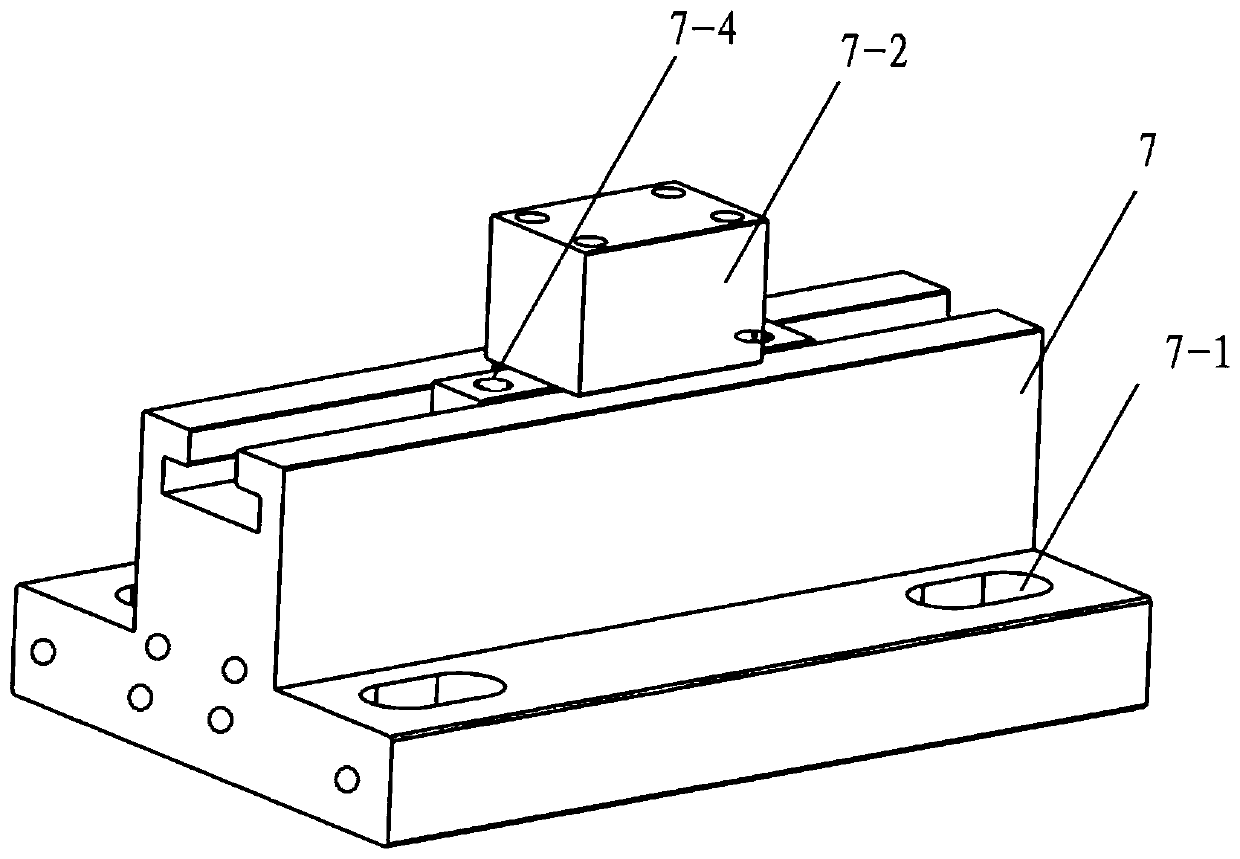

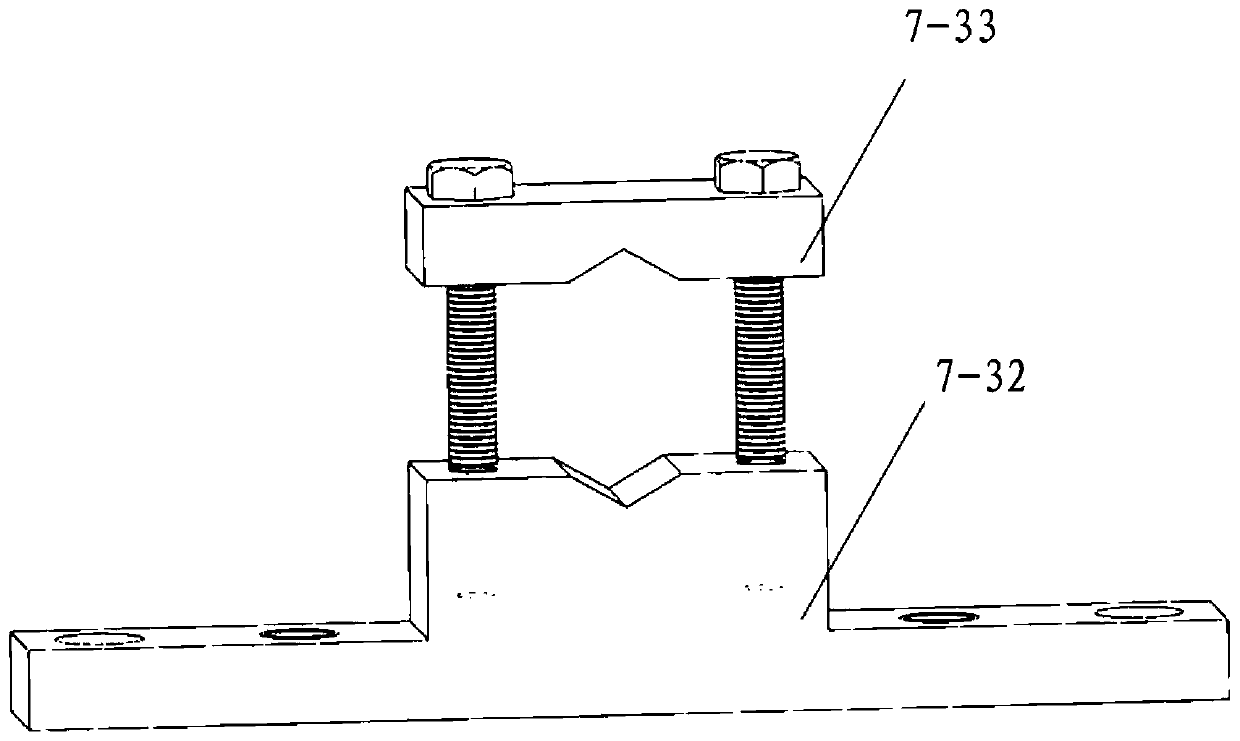

[0026] The sliding mechanism 7 includes: a fixed block 7-1, a sliding block 7-2 and a clamping part 7-3.

[0027] The fixed block 7-1 is fixedly arranged on the base 3.

[0028] The slider 7-2 is slidably arranged on the fixed block 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com