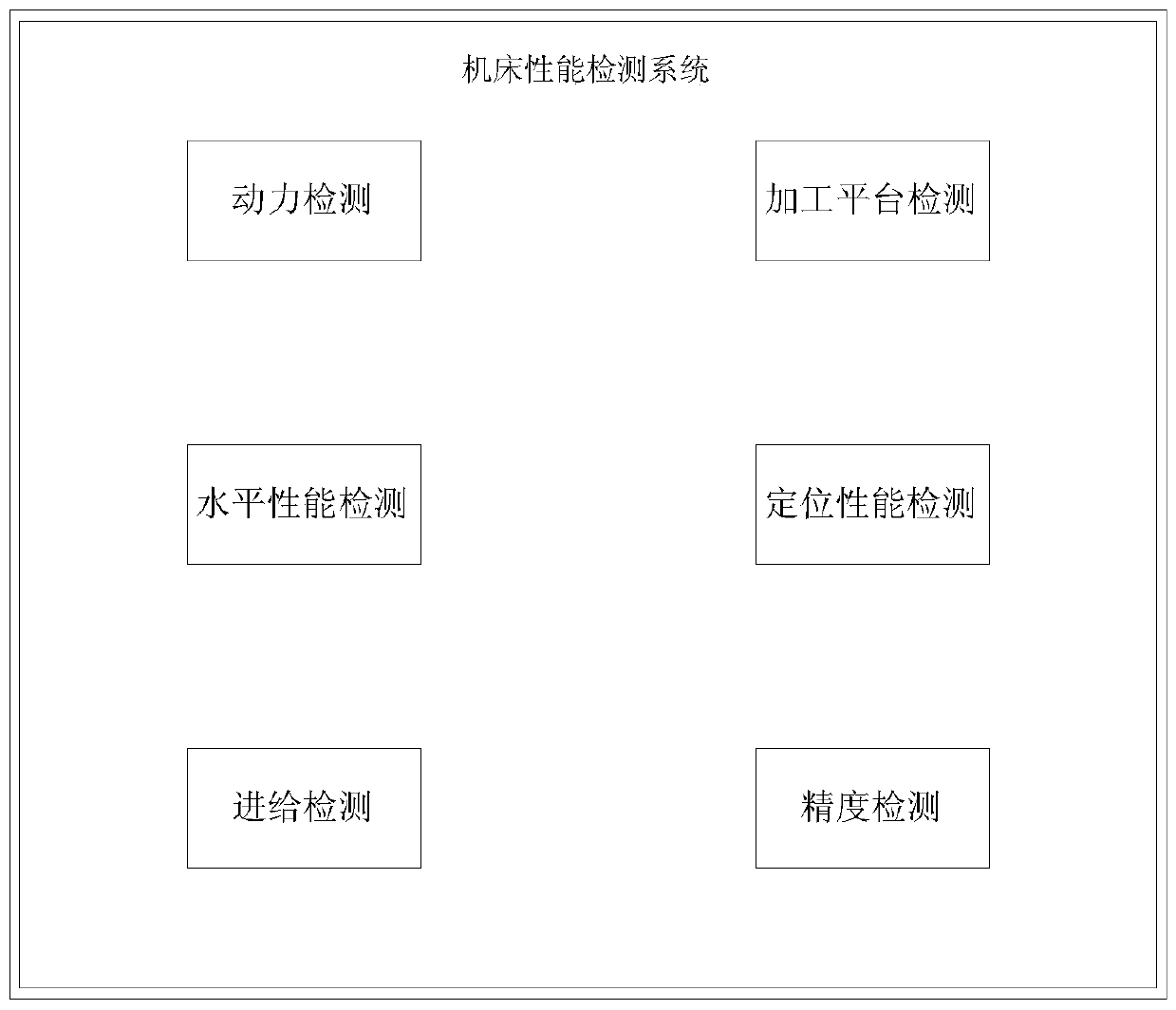

Machine tool performance detection system and method

A detection system and machine tool technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of lack of measurement of key components of the brake, restrictions on the development of machine tool calibration and maintenance work, and achieve intuitive analysis of various item performance, simplify the performance testing process, and ensure the effect of accuracy and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

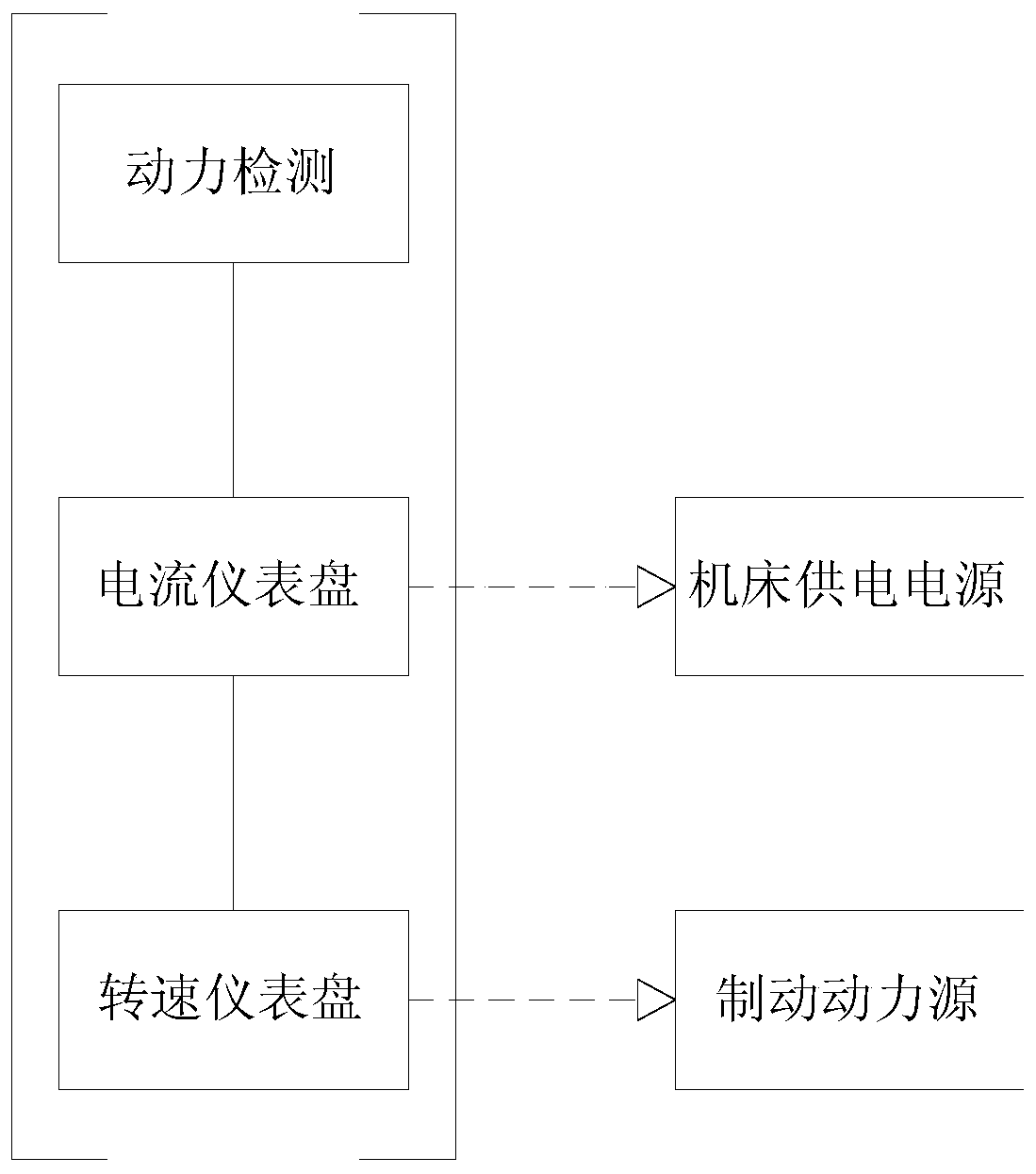

[0038] After turning off the power supply of the machine tool, set the current instrument panel in series between the transmission motor and the PLC industrial control module, and set the speed instrument panel in series between the transmission motor and the power supply line. The measurement specifications of the current instrument panel and the speed instrument panel depend on the machine tool. The power and the power of the brake motor are determined, and the speed instrument panel is selected according to the different brake power sources of the machine tool, and the selection specifications and types are not unique.

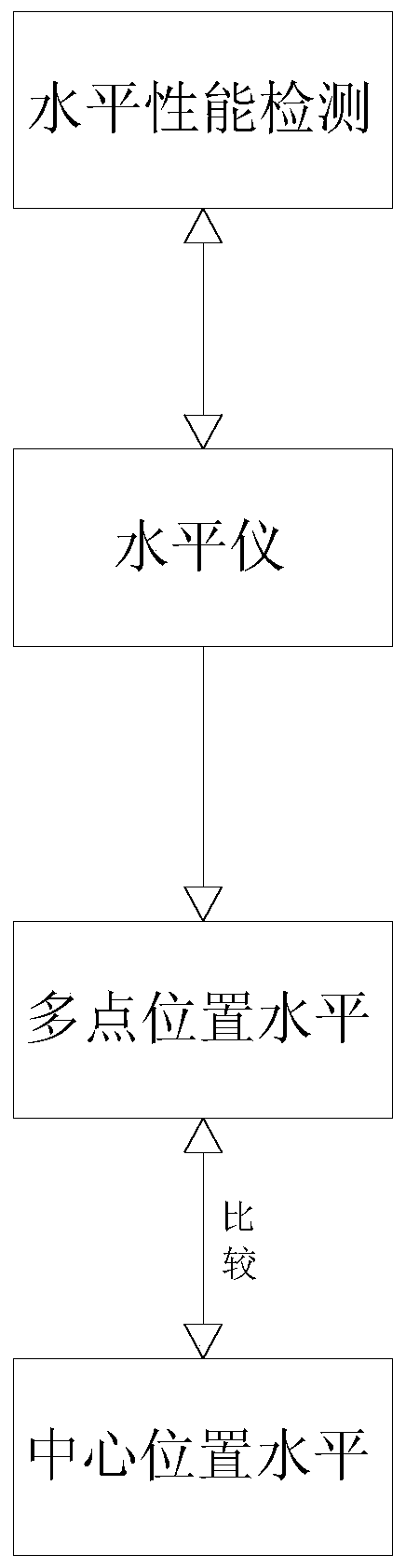

[0039] Horizontal performance testing is used to measure the corners of the machine tool, local horizontal position and horizontal stability. The horizontal performance testing includes a level gauge. The level gauge is set at each corner position of the machine tool processing area according to the horizontal height and length of the machine tool. The level ...

Embodiment 2

[0041] First set the level probe in the middle of the machine tool to reset the value to zero, and then set the level probe at the corner position of the machine tool. The measuring positions of the probes are distributed at equal intervals along the outer edge of the machine tool according to the total length of the machine tool. According to the level probe Record the horizontal position of the eight points of the machine tool to analyze the level of the machine tool by comparing the difference between the horizontal position height of the edge and the horizontal height of the center.

[0042] The feed detection is used to measure the stability of the track components in the X-axis, Y-axis, and Z-axis directions of the machine tool. The feed detection includes the PLC industrial control module of the machine tool. The feed detection controls the X-axis, Y-axis, and Z-axis track components of the machine tool through the PLC industrial control module. Here, the PLC industrial ...

Embodiment 3

[0045] By fixing multiple dial gauges at each corner of the processing platform, the horizontal height values of each corner point of the processing platform are recorded by the dial gauge, and the inspectors analyze the processing platform through difference comparison.

[0046] The positioning performance test includes the processing head parts. The positioning performance test is used to measure the X-axis, Y-axis, Z-axis direction track in the machine tool, and the positioning performance of the processing head parts. The positioning performance test is based on the PLC industrial control module control in the feed test. The positioning performance The detection is based on the judgment of the stability of the X-axis, Y-axis, and Z-axis directions when the screw of the machine tool is active. Active location to analyze positioning performance through location difference comparison;

[0047] Accuracy detection is used to measure the position accuracy of track components a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com