Prefabricated steel truss concrete composite structure assembly type superposed beam and manufacturing method thereof

A combined structure and assembly technology, applied in the direction of structural elements, manufacturing tools, building structures, etc., can solve the problems of great impact on floor height and complex nodes, so as to reduce construction period and quality impact, reduce construction period, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

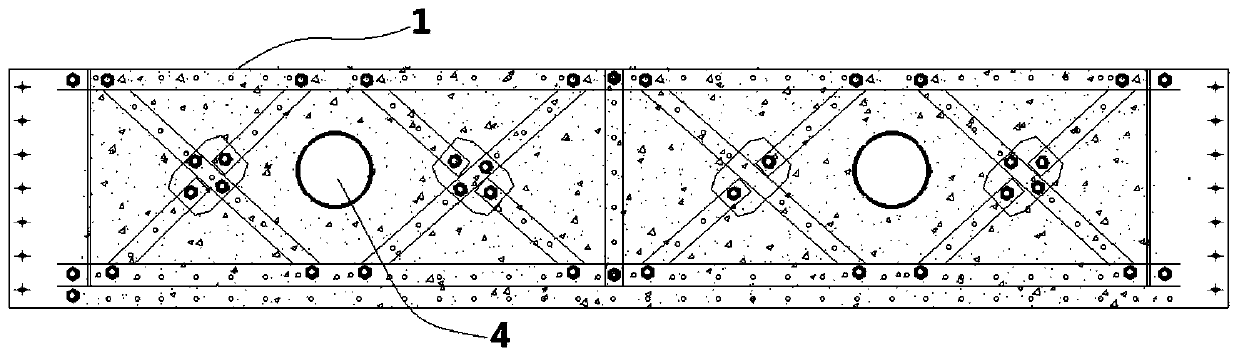

[0045] This embodiment discloses an assembled composite beam of a prefabricated steel truss concrete composite structure, which includes an assembled steel truss 1 and a crack-resistant reinforcement cage.

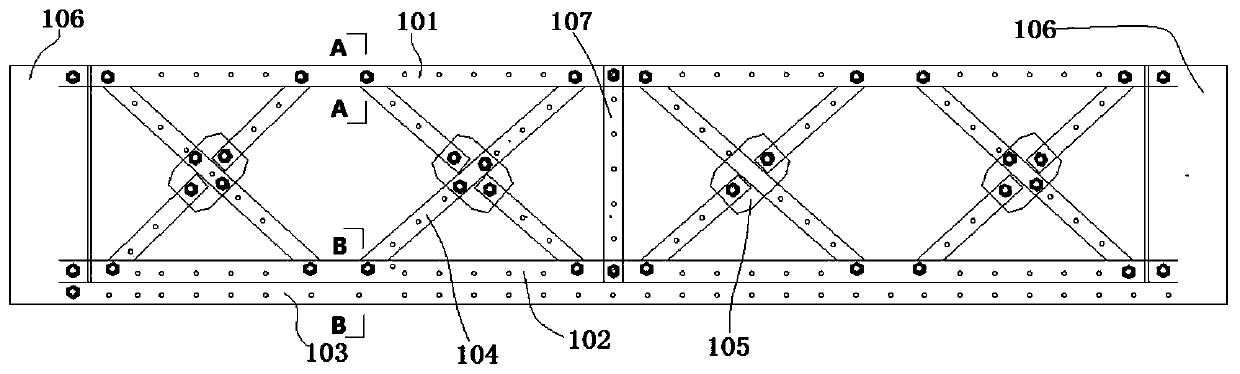

[0046] see figure 2 , the fabricated steel truss 1 includes a steel frame upper beam 101 , a steel frame lower beam I 102 , a steel frame lower beam II 103 and several steel frame support crosses 104 .

[0047] The upper beam 101 of the steel skeleton, the lower beam I 102 of the steel skeleton and the lower beam II 103 of the steel skeleton are parallel to each other, the lower beam I 102 of the steel skeleton is located directly below the upper beam 101 of the steel skeleton, and the lower surface of the lower beam I 102 of the steel skeleton is connected with a lower surface of the steel skeleton. Beam II 103.

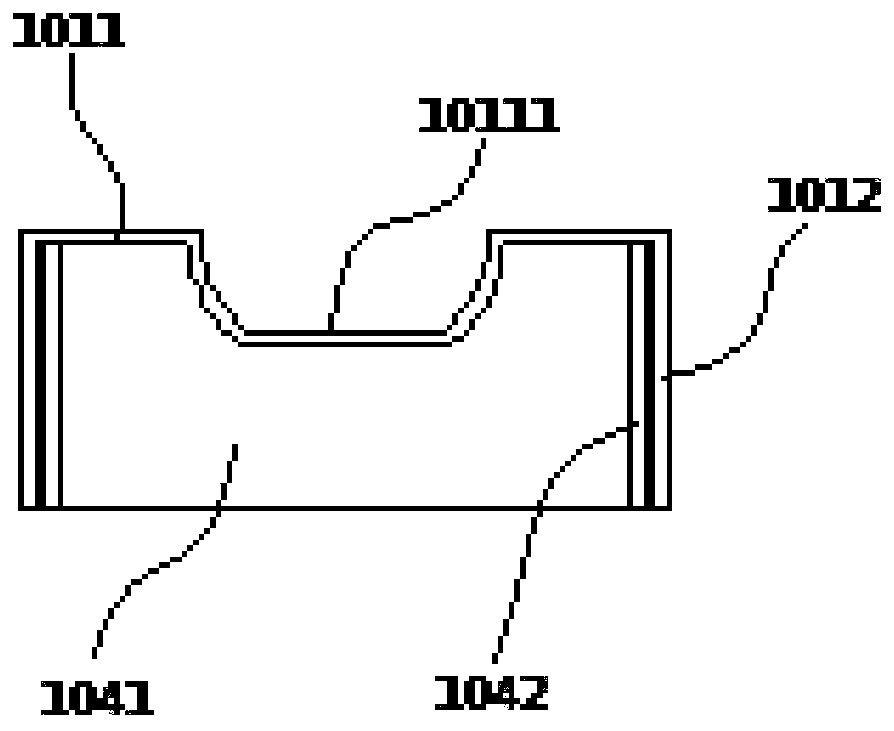

[0048] see Figure 5Or 6, the upper beam 101 of the steel skeleton is a channel steel with the notch facing downward, the upper beam 101 of the steel skeleto...

Embodiment 2

[0063] Based on the prefabricated steel truss concrete composite structure assembled composite beam described in Embodiment 1, this embodiment discloses a manufacturing method of the composite beam, including the following steps:

[0064] 1) The steel frame upper beam 101 , the steel frame lower beam I 102 , the steel frame lower beam II 103 and the steel frame supporting cross 104 are processed by using steel strips.

[0065] 2) Process the steel frame upper beam 101, steel frame lower beam I 102, steel frame lower beam II 103, steel frame support cross 104, steel frame support connecting plate 105, connecting plate I 106 and connecting plate II 107 by bolting or welding Assembled steel truss1.

[0066] 3) Install the anti-cracking reinforcement cage on the periphery of the fabricated steel truss 1 . Wherein, the anti-cracking steel cage is formed by splicing several steel mesh pieces, and these steel mesh pieces are steel mesh pieces bound on site or finished steel mesh pie...

Embodiment 3

[0070] This embodiment discloses an assembled composite beam of a prefabricated steel truss concrete composite structure, which includes an assembled steel truss 1 and a crack-resistant reinforcement cage.

[0071] see figure 2 , the fabricated steel truss 1 includes a steel frame upper beam 101 , a steel frame lower beam I 102 , a steel frame lower beam II 103 and several steel frame support crosses 104 .

[0072] The upper beam 101 of the steel skeleton, the lower beam I 102 of the steel skeleton and the lower beam II 103 of the steel skeleton are parallel to each other, the lower beam I 102 of the steel skeleton is located directly below the upper beam 101 of the steel skeleton, and the lower surface of the lower beam I 102 of the steel skeleton is connected with a lower surface of the steel skeleton. Beam II 103.

[0073] The ends of the upper beam 101 of the steel frame, the lower beam I 102 of the steel frame and the lower beam II 103 of the steel frame are connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com