Manufacturing method of casting mold

A technology of casting molds and manufacturing methods, applied in the direction of processing and manufacturing, manufacturing auxiliary devices, casting molding equipment, etc., can solve the problems of low manufacturing efficiency, high cost, unsuitable for small batch production, difficult to manufacture complex shapes, etc., and achieve manufacturing cost Obvious, low manufacturing difficulty, accurate manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

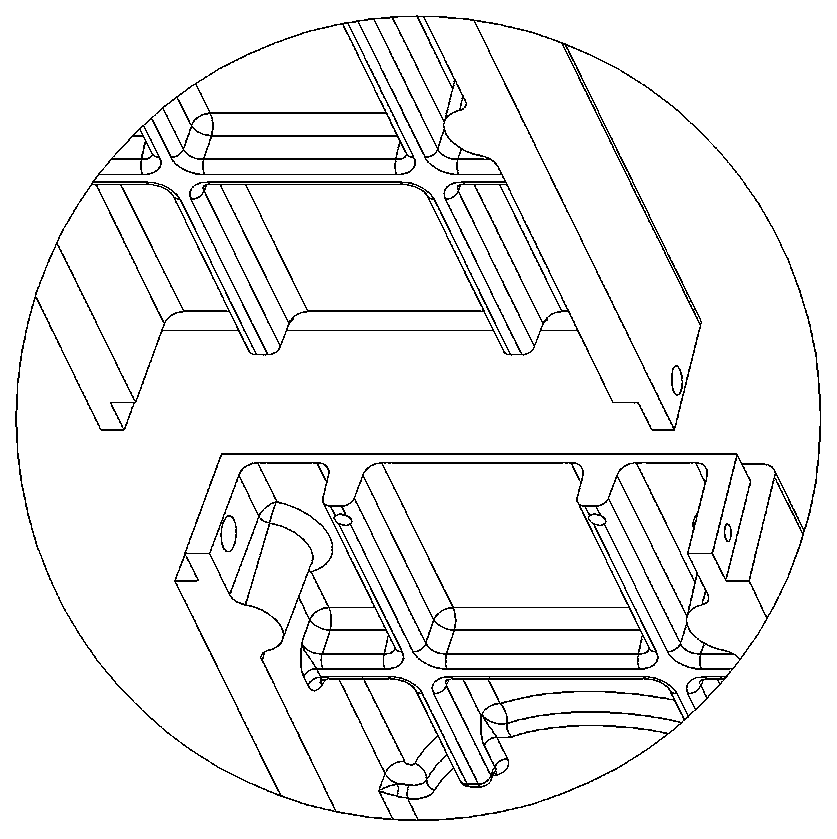

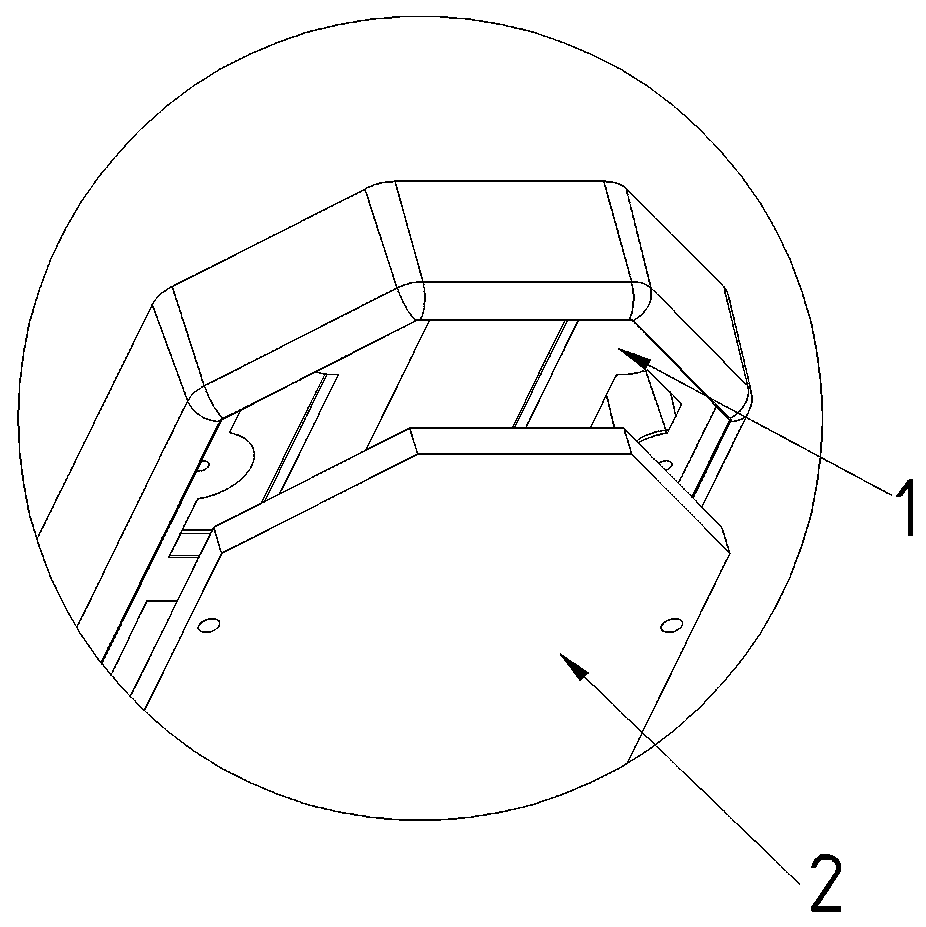

[0023] [Example 1] When the maximum size of the casting mold is smaller than the maximum printing size of the 3D printer, the overall printing of the mold is carried out according to the following steps.

[0024] Step 1. Use 3D mechanical design software to design the casting mold, including the determination of casting slope, casting shrinkage, machining allowance, parting surface and other parameters. After the design is completed, generate an STL format model that can be accepted by the 3D printing slicing software document.

[0025] Step 2: Use 3D printing slicing software to slice the model file of the casting mold, including parameters such as printing temperature, outer layer thickness, and internal filling rate, and generate a general print file in GCODE format acceptable to the 3D printer after processing.

[0026] Step 3, import the general print file into the 3D printer for casting mold printing.

[0027] Step 4, the surface treatment of the casting mold, first rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com