Preparation method of deep water-rich sand layer diaphragm wall groove wall reinforcing material

A technology of water-rich sand layer and reinforcement materials, which is applied in cement mixing devices, chemical instruments and methods, excavation, etc. The effect of improving stability and increasing the speed of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described below in conjunction with accompanying drawing and embodiment:

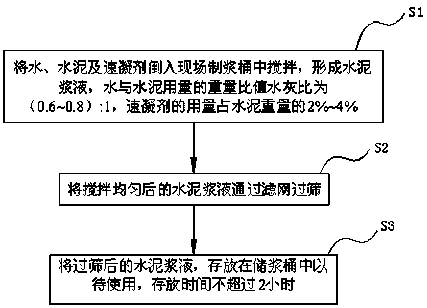

[0023] Such as figure 1 As shown, an embodiment of the present invention provides a method for configuring reinforcement materials for a deep and thick water-rich sand layer connecting wall and groove wall, which is characterized in that it includes the following steps:

[0024] Step S1: Pour water, cement and quick-setting agent into the on-site slurry tank and stir to form cement slurry. The weight ratio of water to cement is (0.6~0.8):1, and the amount of quick-setting agent accounts for 2%~4% of the weight. The water-cement ratio is strictly controlled by adding water to the on-site pulping barrel through a quantitative container.

[0025] Step S2: Sieve the uniformly stirred cement slurry through a filter, and remove hard cement blocks to ensure the quality of piles;

[0026] Step S3: Store the sieved cement slurry in a slurry storage tank for use. The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com