Production method of steel wear-resisting plate BTW for coal mine

A production method and wear-resistant plate technology, applied in the field of metallurgy, can solve the problems of poor stability of strength and impact performance, poor hardenability of steel plates, lack of supercooling, etc., and achieve the effect of good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

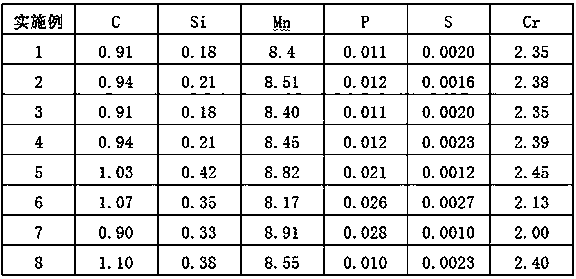

[0023] The BTW thickness of the coal mine steel wear-resistant plate in this example is 40 mm, and its chemical composition and mass percentage are shown in Table 1.

[0024] The production method of the steel wear-resistant plate BTW for coal mines in this embodiment includes billet opening, billet heating, high-pressure water dephosphorization, rolling, cooling, and straightening processes, specifically including the following steps:

[0025] (1) Ingot billet opening process, the thickness of the billet is 250mm;

[0026] (2) Billet heating process, the temperature of the preheating section is 710°C, the temperature of the heating section is 950°C, the temperature of the second heating section is 1180°C, the temperature of the third heating section is 1260°C, and the temperature of the soaking section is 1250°C;

[0027] (3) High-pressure water dephosphorization process. In order to ensure the surface quality of the billet, high-pressure water descaling is used in the rollin...

Embodiment 2

[0033] The BTW thickness of the steel wear-resistant plate for coal mine in this example is 45 mm, and its chemical composition and mass percentage are shown in Table 1.

[0034] The production method of the steel wear-resistant plate BTW for coal mines in this embodiment includes billet opening, billet heating, high-pressure water dephosphorization, rolling, cooling, and straightening processes, specifically including the following steps:

[0035] (1) Ingot billet opening process, the thickness of the billet is 220mm;

[0036] (2) Billet heating process, the temperature of the preheating section is 720°C, the temperature of the heating section is 944°C, the temperature of the second heating section is 1193°C, the temperature of the third heating section is 1258°C, and the temperature of the soaking section is 1246°C;

[0037] (3) High-pressure water dephosphorization process. In order to ensure the surface quality of the billet, high-pressure water in the rolling mill is used...

Embodiment 3

[0043] The BTW thickness of the steel wear-resistant plate for coal mine in this example is 20 mm, and its chemical composition and mass percentage are shown in Table 1.

[0044] The production method of the steel wear-resistant plate BTW for coal mines in this embodiment includes billet opening, billet heating, high-pressure water dephosphorization, rolling, cooling, and straightening processes, specifically including the following steps:

[0045] (1) Ingot billet opening process, the thickness of the billet is 180mm;

[0046] (2) Billet heating process, the temperature of the preheating section is 715°C, the temperature of the heating section is 925°C, the temperature of the second heating section is 1183°C, the temperature of the third heating section is 1261°C, and the temperature of the soaking section is 1256°C;

[0047] (3) High-pressure water dephosphorization process. In order to ensure the surface quality of the steel billet, high-pressure water descaling is used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com