Lidar-assisted feedforward wind measurement individual pitch control method of wind generating set

A technology of wind turbines and laser radar, which is applied in the control of wind turbines, wind turbines, engine control, etc., can solve problems such as uneven force on the impeller plane, load sensor reliability problems, real-time feedback problems, etc., to achieve wind speed Real and effective, avoiding the decline of correlation, and timely compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples.

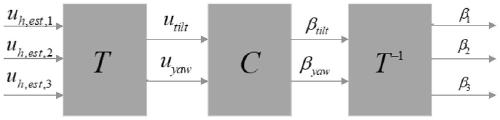

[0026] The independent pitch control method of the wind power generating set provided in this embodiment is based on lidar feedforward wind measurement, and its input is the wind speed near the plane of the impeller, whether the lidar is installed on the nacelle or the hub of the wind generating set, When measuring the wind speed near the impeller plane, there is a large measurement angle relative to the axis of the hub, and the correlation between the effective wind speed of the blade and the measured wind speed will decrease; based on this, a telescope is installed on each blade It is used to observe the incoming wind speed. It is connected with the radar system installed in the hub through optical fiber to form a telescope radar system, which can measure the wind speed of each blade near the plane of the impeller without a large measurement angle.

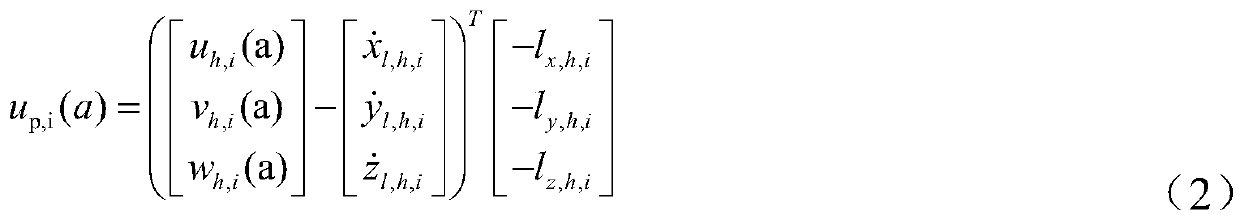

[0027] Define the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com