Rock debris flow measuring device and method

A flow measurement device and cuttings technology, which is applied in the field of oil drilling, can solve the problems of slow turning speed, uncontrollability, and influence on collection and measurement, and achieve the effects of weight reduction, convenient handling and installation, and simplified external connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

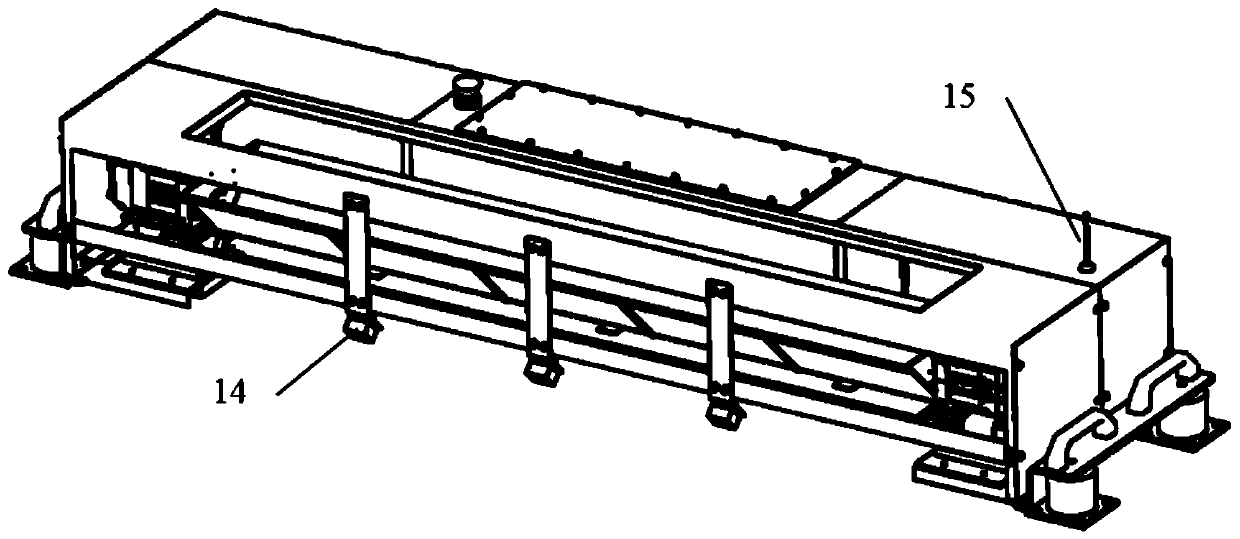

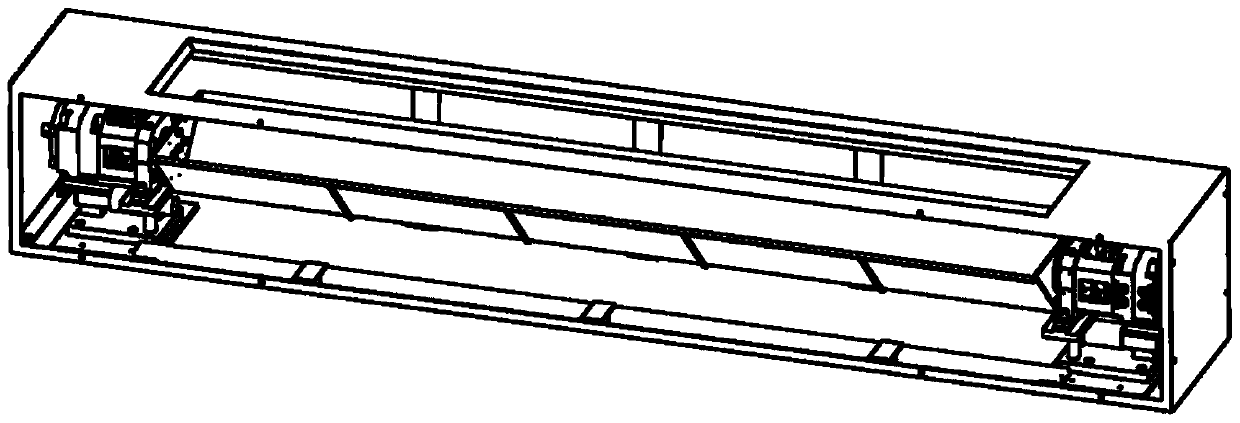

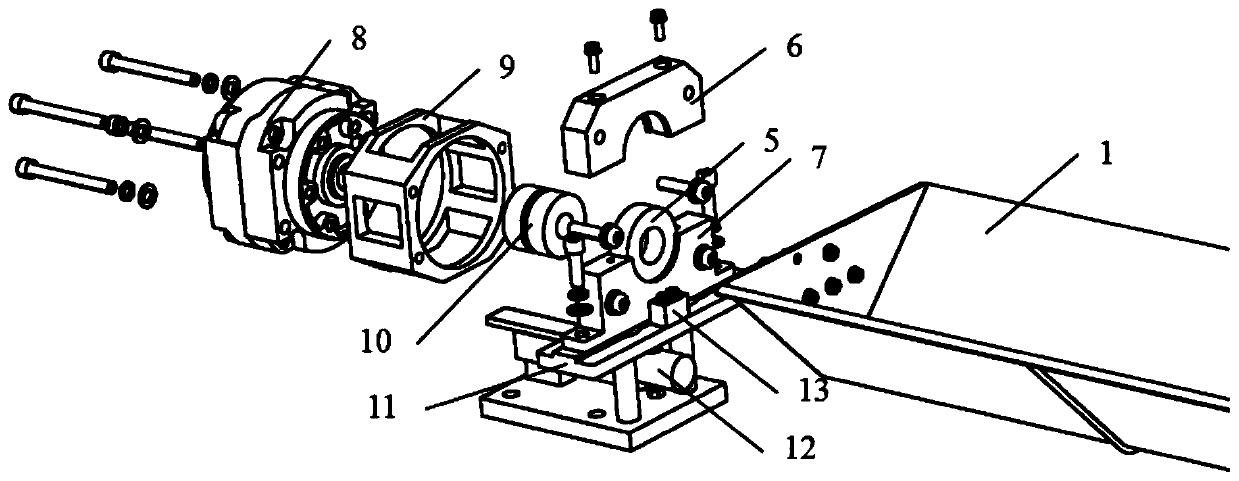

[0029] Example 1, such as Figure 1-5 As shown, this embodiment discloses a cuttings flow measurement device, which includes the outer skeleton of the weighing sand dumping assembly and the control box connected together, and a load cell is installed on the bottom of both sides of the outer skeleton of the weighing sand dumping assembly 12, and the bearing bracket mounting plate 11 is installed on the load cell, the bearing bracket is installed on the bearing bracket mounting plate, and the bearing 5 is installed in the bearing mounting hole on the bearing bracket by interference fit, on the inner side of the bearing bracket Block 13 is installed, the cylinder installation frame 9 is installed on the outside, and the rotary cylinder 8 is installed in the cylinder installation frame. A collision block 3 and a support shaft 4 are respectively installed on both sides of the V-shaped groove 1, and the two support shafts are inserted respectively. The adjacent bearings are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com