A mechanical stirring tank and an experimental measurement device for simulating deep sea oil and gas drilling process

A mechanical stirring and oil and gas drilling technology, applied in the field of offshore oil and gas exploration, can solve problems such as oil and gas drilling and production operation hazards, geological disasters, changes in drilling fluid performance, etc., to achieve the effect of reducing production costs and environmental pollution, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

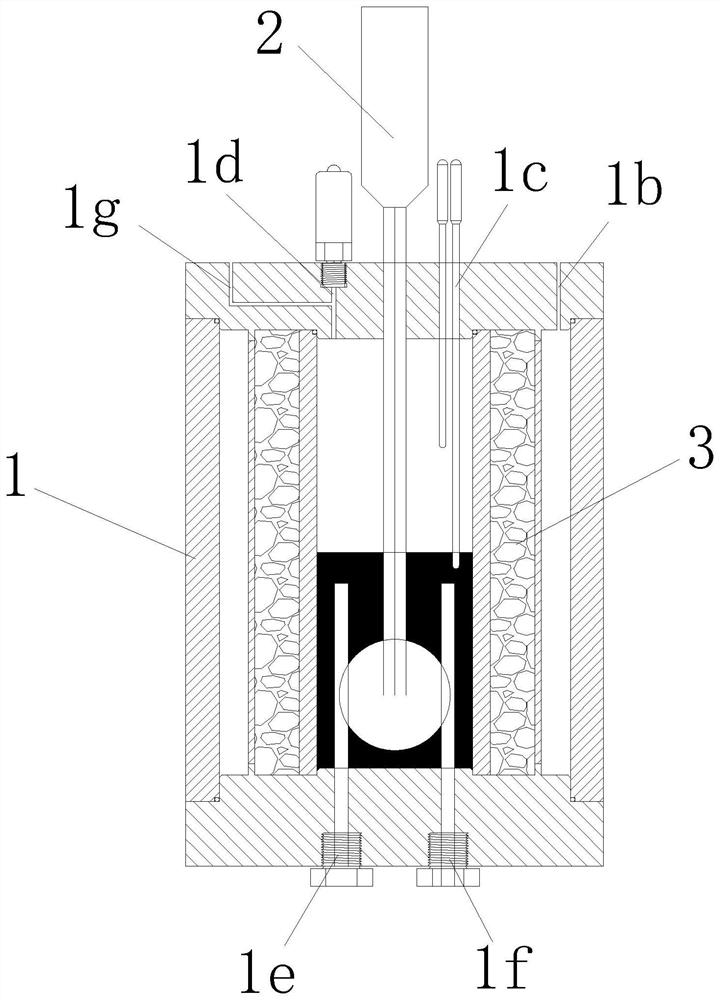

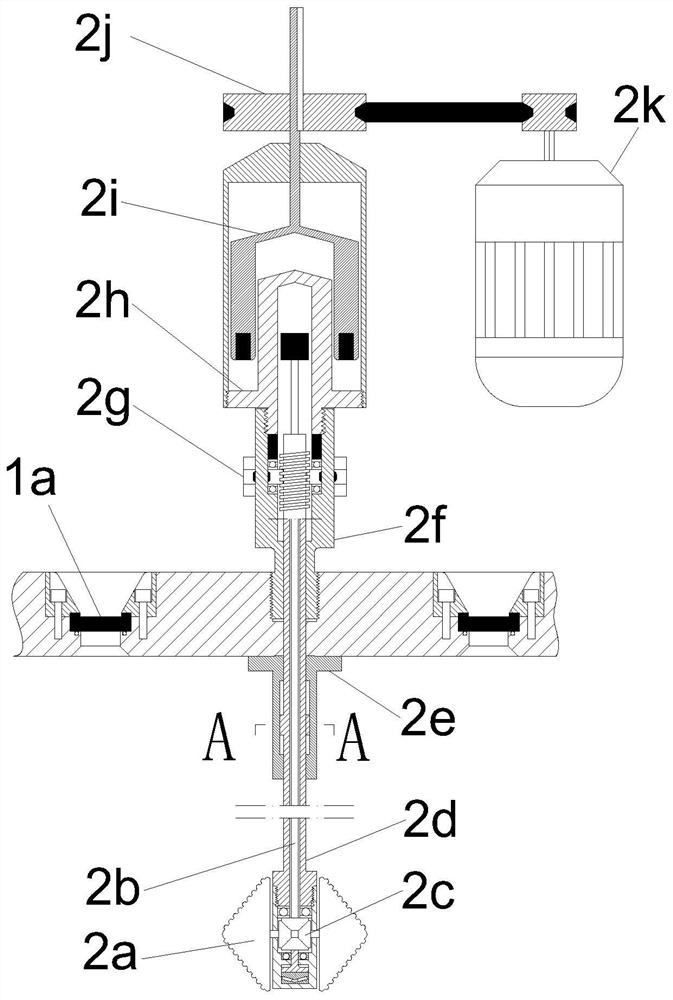

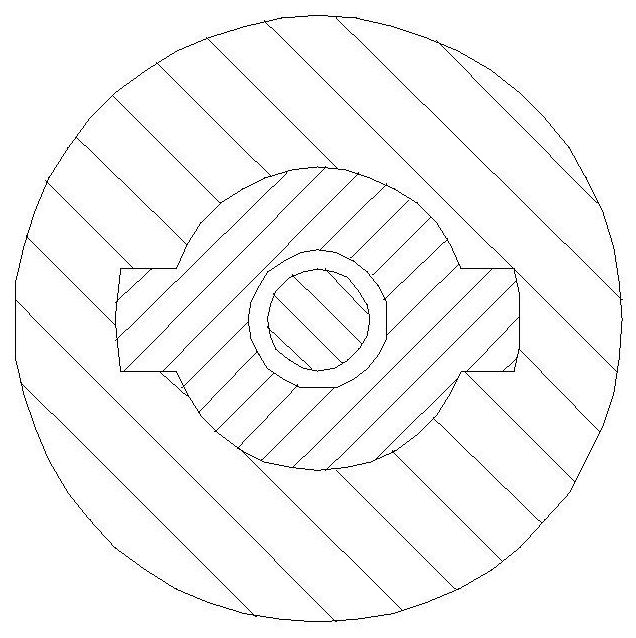

[0035] refer to Figure 1-3 As shown, the high-pressure-resistant visual mechanical stirring tank for simulating deep-sea oil and gas drilling provided in this embodiment includes a tank body 1, which is a cylindrical high-pressure stainless steel container, and its upper end cover is provided with an axially movable Mechanical agitator 2, two symmetrically distributed observation holes 1a, high-pressure air inlet 1b, high-pressure exhaust hole 1g, temperature sensor jack 1c, pressure sensor jack 1d, the lower end cover of the kettle body is provided with drilling fluid feeding Port 1e and discharge port 1f. An annular wall surface 3 capable of gas leakage is provided inside the kettle body. The annular wall surface 3 is coaxial with the kettle body 1 and separates the inner space of the kettle body into two layers, the inner layer is a simulated drill bit that contains gas in the leakage The environment of the drilling process in the formation, the drilling fluid and the mec...

Embodiment 2

[0041] refer to Figure 4-5 As shown, the experimental measurement device for simulating the deep-sea oil and gas drilling process provided in this example includes the mechanical stirring tank shown in Example 1, the drilling fluid circulation control system, the gas circulation control system, the temperature control system and the data acquisition system.

[0042] Among them, the drilling fluid circulation control system is used to control the injection and recovery of drilling fluid in the tank body 1 as well as the refurbishment and storage of drilling fluid.

[0043] The gas circulation control system is used to control the flow process of the high-pressure gas in the kettle body 1 . At the same time, in order to reduce the consumption of high-pressure gas in the experiment and improve the efficiency of gas use, the gas circulation control system is also equipped with a gas recovery and recycling device.

[0044] The temperature control system is used to provide a suita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com