Automatic production equipment of shaded pole motor and production method of shaded pole motor

A technology for automatic production of shaded pole motors, applied in the direction of electric components, motor generators, electrical components, etc., can solve the problems of average finished product quality, low degree of automation, and low production efficiency of shaded pole motors, and achieve simple structure and low cost. Labor cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

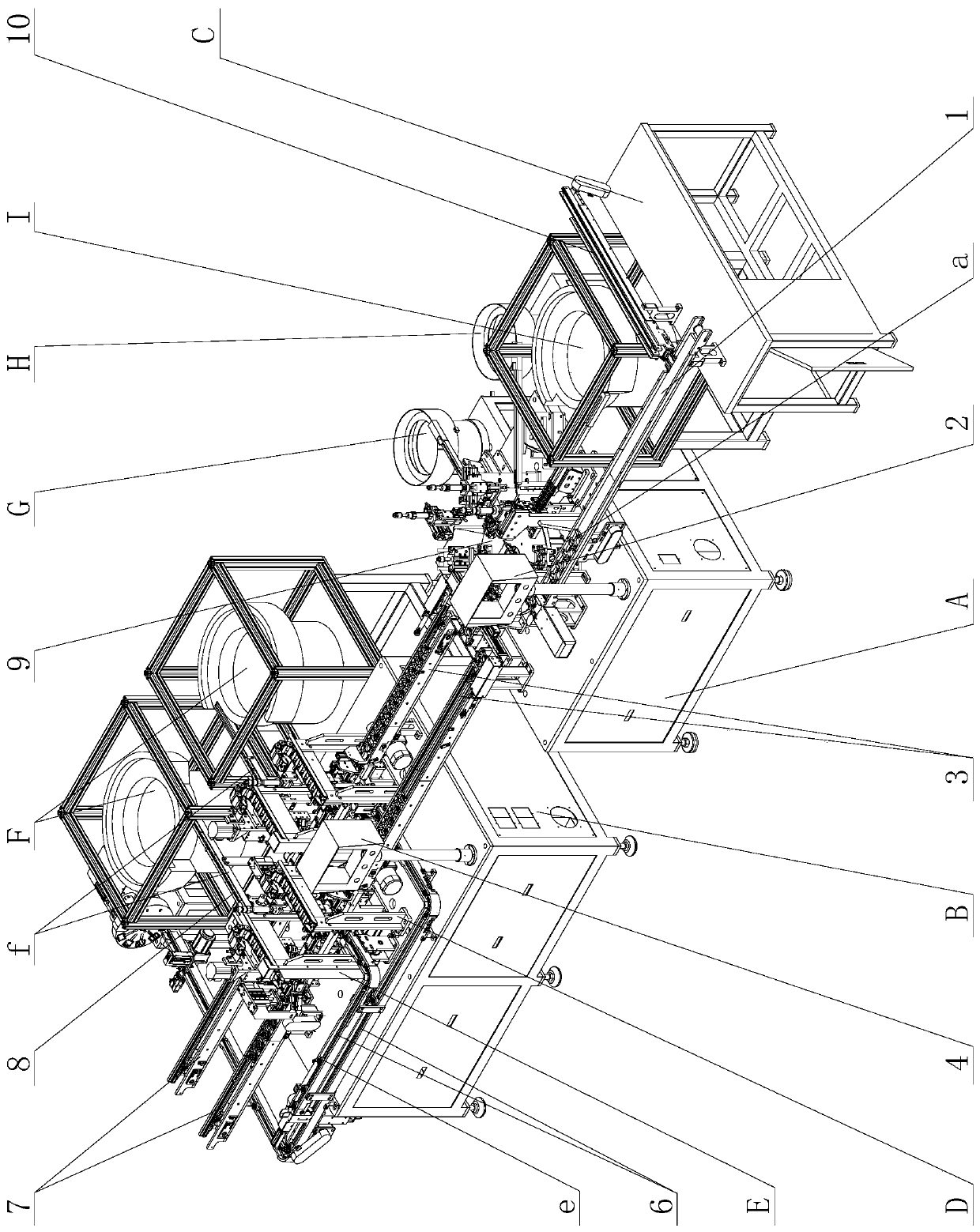

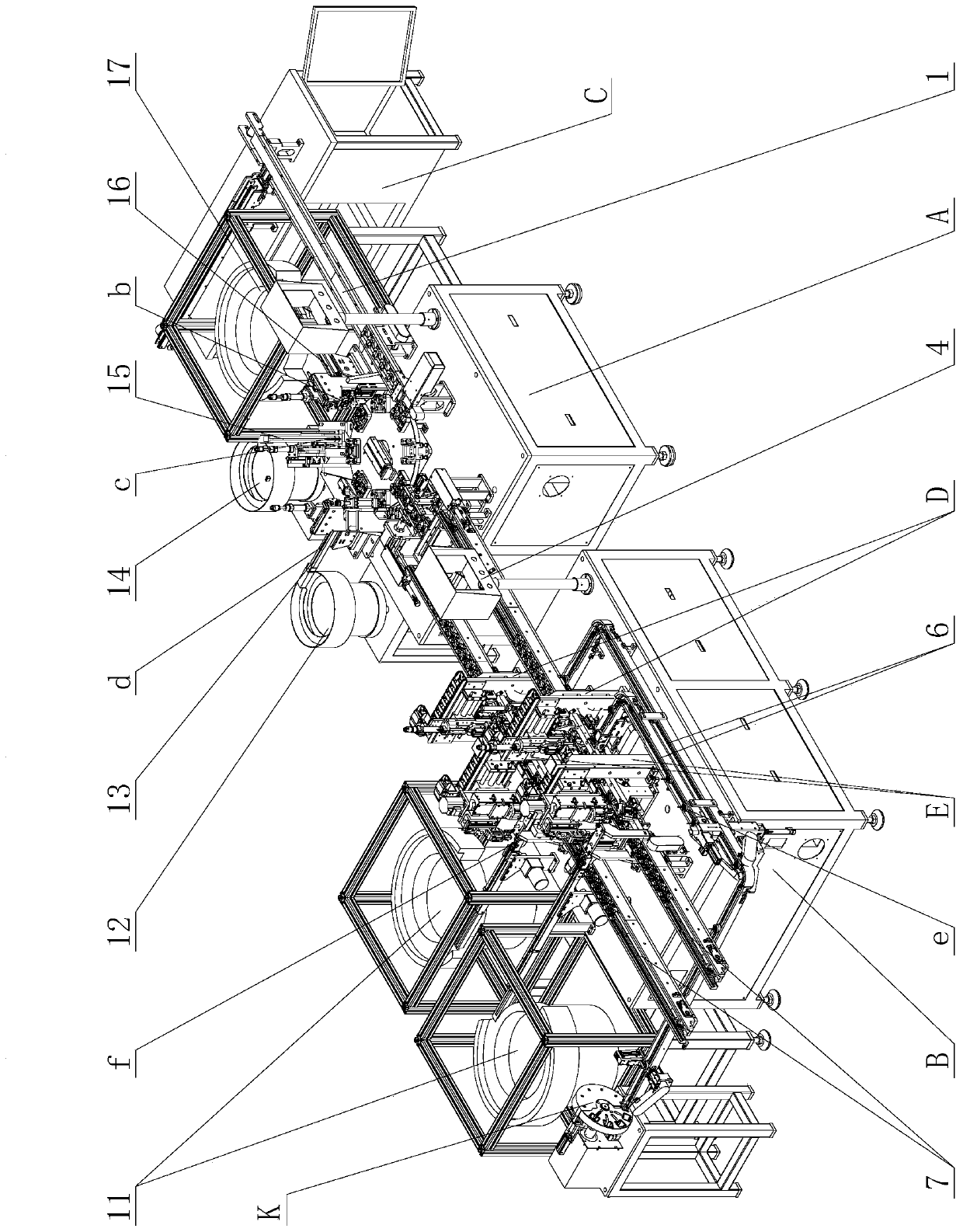

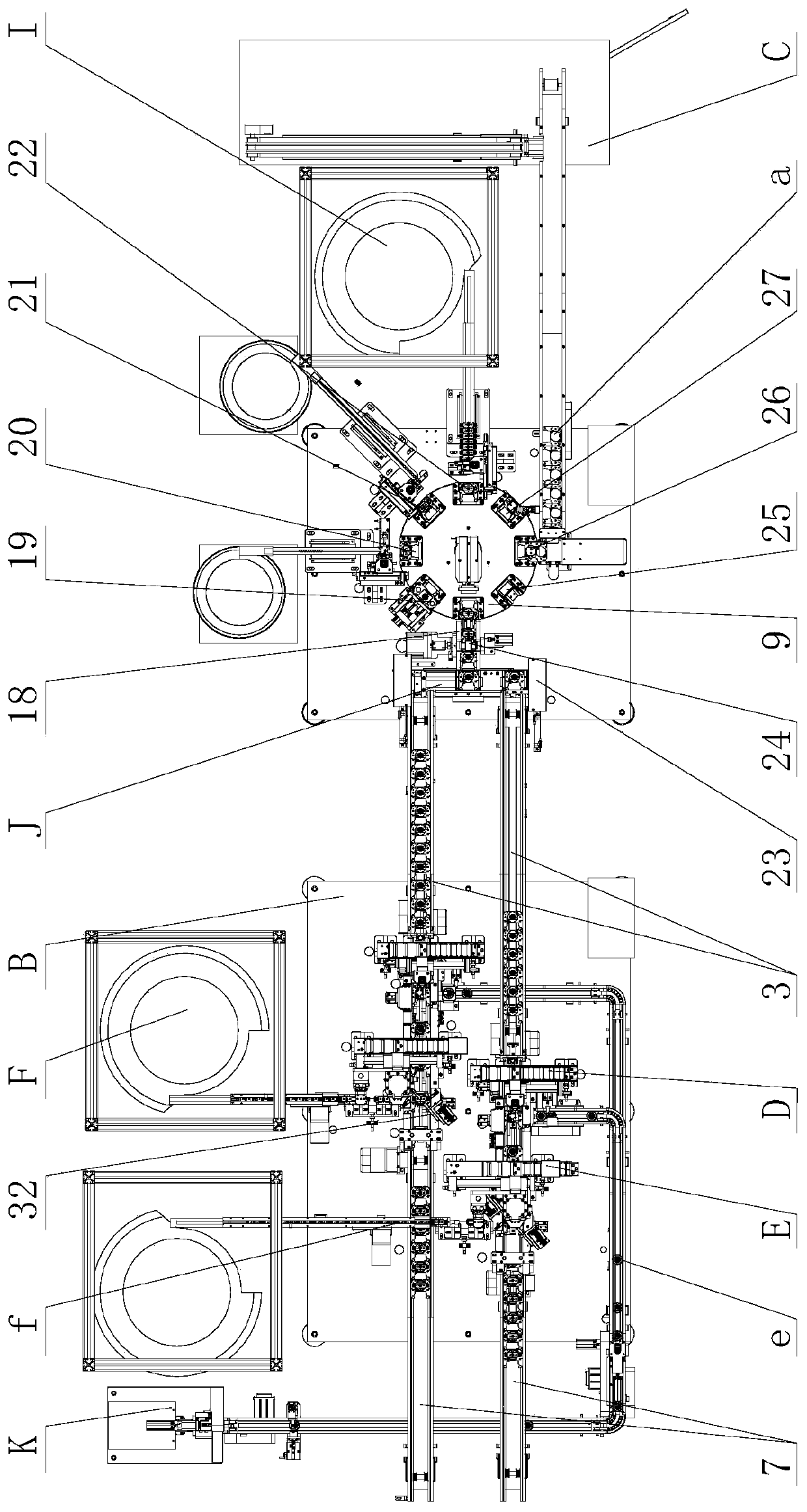

[0032] The present invention will be further described below with reference to the drawings and embodiments.

[0033] See Figure 1-Figure 6 , The automatic production equipment of the shaded pole motor includes a first body A, a second body B and a storage table C. The upper part of the first body A is provided with an indexing plate 9, and the outer circle of the indexing plate 9 is provided with several Each tooling 25 is provided on the circumference side of the indexing plate 9 corresponding to each tooling 25 in a counterclockwise direction with a loading manipulator 26, a stator front and back detection device 27, a lower bracket manipulator 22, a first rivet manipulator 21, a second rivet manipulator 20, and rivet A loading track is provided between the compacting device 19 and the sorting device J, the loading manipulator 26 and the storage table C, and the upper part of the second body B is provided with two rotor transfer assembly devices D and an upper bracket transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com