Gas nozzle quick change method and device for laser equipment

A gas nozzle and air flotation technology, which is used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to process, affect the processing effect, reduce the processing efficiency and effect, etc., to ensure consistency and work stability. Good, improve the effect of processing efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

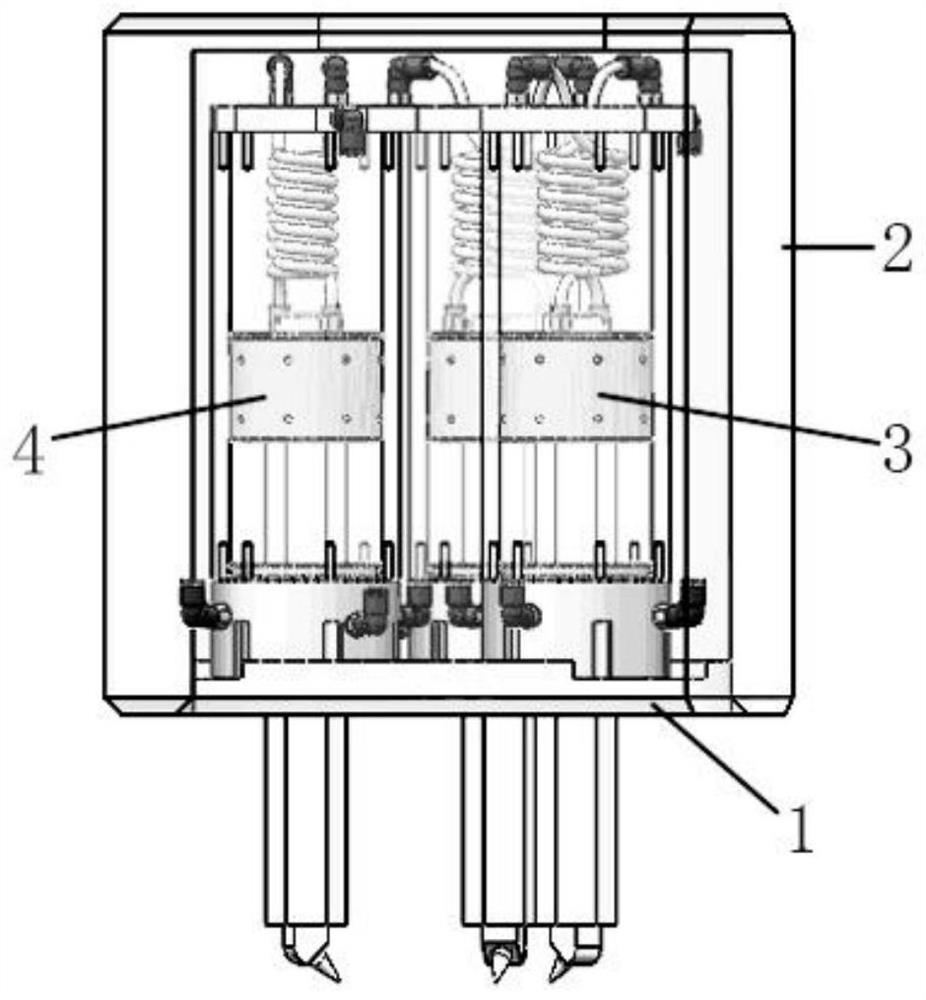

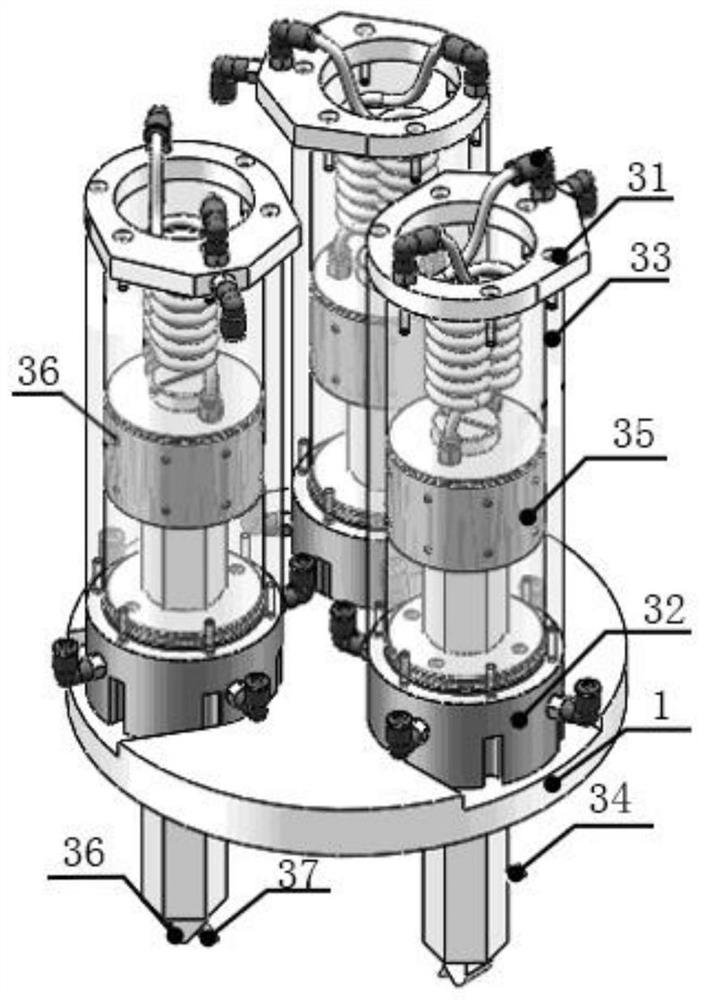

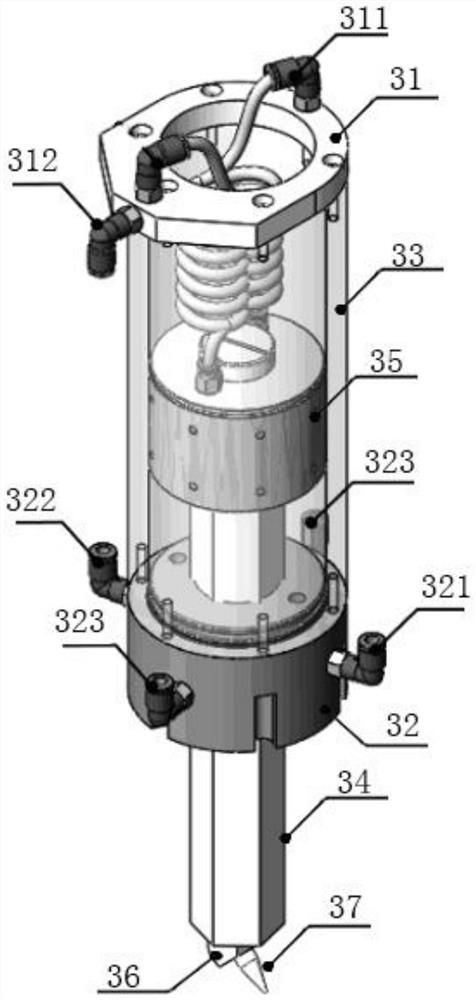

[0035] Example: see Figure 1-Figure 4 , a quick-change air nozzle device provided in this embodiment, which includes a base plate 1, a housing 2, and at least two side-axis quick-change air nozzle assemblies 3 arranged on the base plate 1, at the center of the bottom surface of the base plate, a The electromagnetic locking device 4 is used to absorb or release the coaxial air nozzle 5 .

[0036] In this embodiment, three side-axis quick-exchange nozzle assemblies 3 are symmetrically arranged on the bottom surface of the base plate. In other embodiments, the number of side-axis quick-change air nozzle assemblies 3 can also be two, four or more. The working heights and angles of the air nozzles on each side shaft quick-change air nozzle assembly 3 are different. That is, the lengths of the air-floating piston rods in each side-axis quick-change air nozzle assembly 3 are different; the orientations of the air nozzles in each side-axis quick-change air nozzle assembly 3 are dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com