Production process and production line of blades

A production process and blade technology, which is applied in the production process of blades and its production line, can solve the problems of low production efficiency and achieve the effects of high production efficiency, long service life and accurate cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

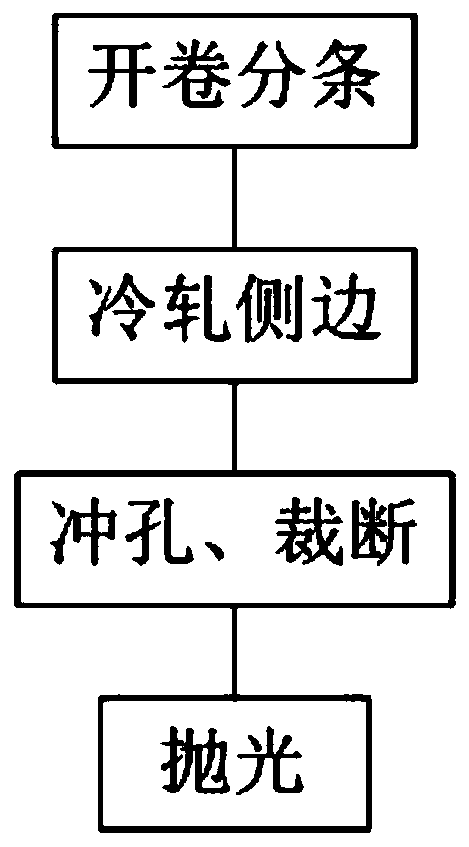

[0030] Embodiment 1: a kind of production technology of blade, comprises the steps:

[0031] Step 1: Pull the rolled austenitic stainless steel coil with a thickness of 3mm and a hardness of 300-390HV on an uncoiler to form a straight strip, and cut the straight strip by a shearing machine to obtain a long preform;

[0032] Step 2: Cold rolling the two sides of the preform through a cold rolling mill until the sides are sharp to form a knife edge to obtain an isosceles trapezoidal knife blank, and the hardness of the knife edge area is not less than 450HV;

[0033] Step 3: Punch and cut the blank on the press at the same time to obtain the blade;

[0034] Step 4: Polish and assemble the blade.

Embodiment 2

[0035] Embodiment 2: a kind of production technology of blade, comprises the steps:

[0036] Step 1: Slitting the rolled austenitic stainless steel coil with a thickness of 4mm and a hardness of 200-300HV on a slitting machine into straight strip preforms;

[0037] Step 2: Cold rolling the two sides of the preform through a cold rolling mill until the sides are sharp to form a knife edge to obtain a parallelogram blank, and the hardness of the knife edge area is not less than 400HV;

[0038] Step 3: punching and punching the blank on the press at the same time to obtain the blade;

[0039] Step 4: Polish and assemble the blade.

Embodiment 3

[0040] Embodiment 3: A kind of blade production line, comprises slitting machine, shearing machine, cold rolling mill, press and polishing machine successively, and slitting machine is stripped into the strip preform of metal rolled coil, and cold rolling mill will prefabricated The two sides of the billet are cold-rolled to form a blade, the press is used to punch the installation hole and cut the blade to form a blade, and the polishing machine is used to polish the blade.

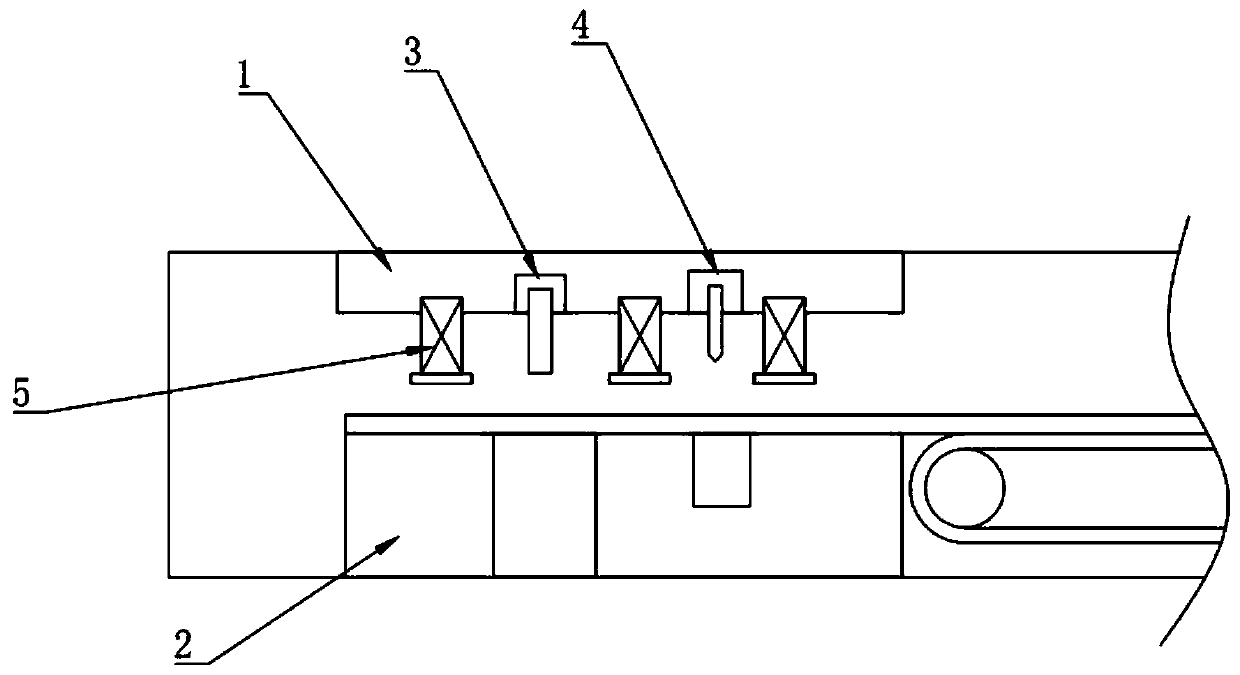

[0041] Such as figure 2 As shown, the press includes a feeding device and a punching die, and the punching die includes an upper template, a lower template, a guide post, a guide sleeve, a punch fixing plate 1 and a die fixing plate 2, and the upper template is fixed with a punching punch 3, Cutting punch 4 and pressing device 5, punching punch 3 is positioned at the conveyor belt side that cutting punch 4 is away from, and punching punch 3 comprises punching pin, and cutting punch 4 comprises cutting k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com