Working condition self-adaptation high-speed milling machining process tool monitoring method and system

A high-speed milling and machining process technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the algorithm model cannot be adapted, cannot effectively process the time series, and the accuracy of wear state recognition is low. The effect of improving the ability to adapt to multiple working conditions, improving the monitoring accuracy, and improving the recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

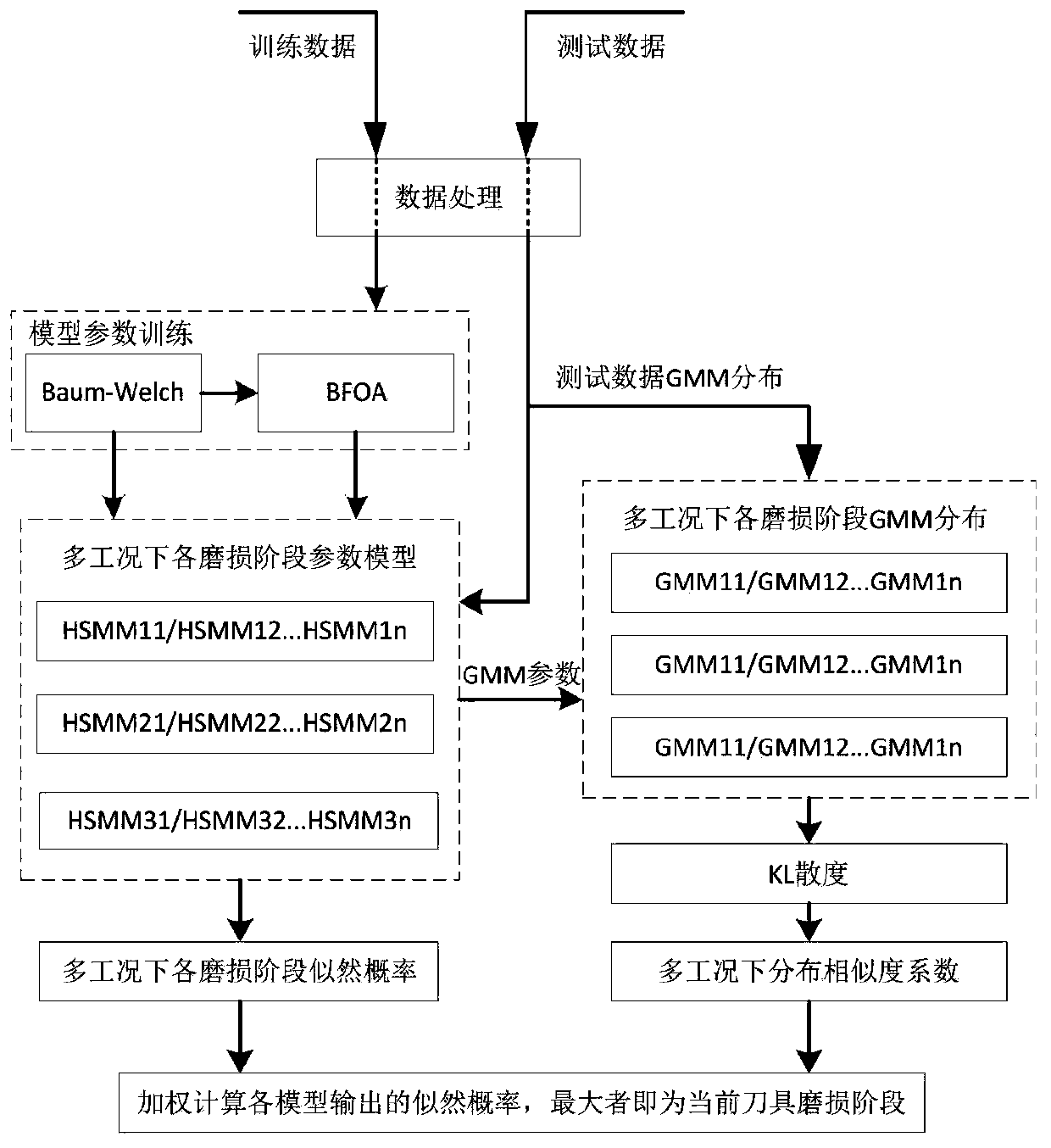

[0055] A working condition self-adaptive tool monitoring method for high-speed milling, comprising the following steps:

[0056] Step 1: Obtain raw sensor signals and measure tool wear

[0057] Such as figure 1 As shown, multiple groups of milling experiments were implemented, and the three-way vibration signals, three-way cutting force signals and one-way acoustic emission signals under different milling conditions were collected through the data acquisition module; at the same time, the actual wear of the tool was measured by an electron microscope, and the measured values were saved. The obtained sensor signal and the actual wear amount of the tool.

[0058] Step 2: Signal preprocessing and feature extraction

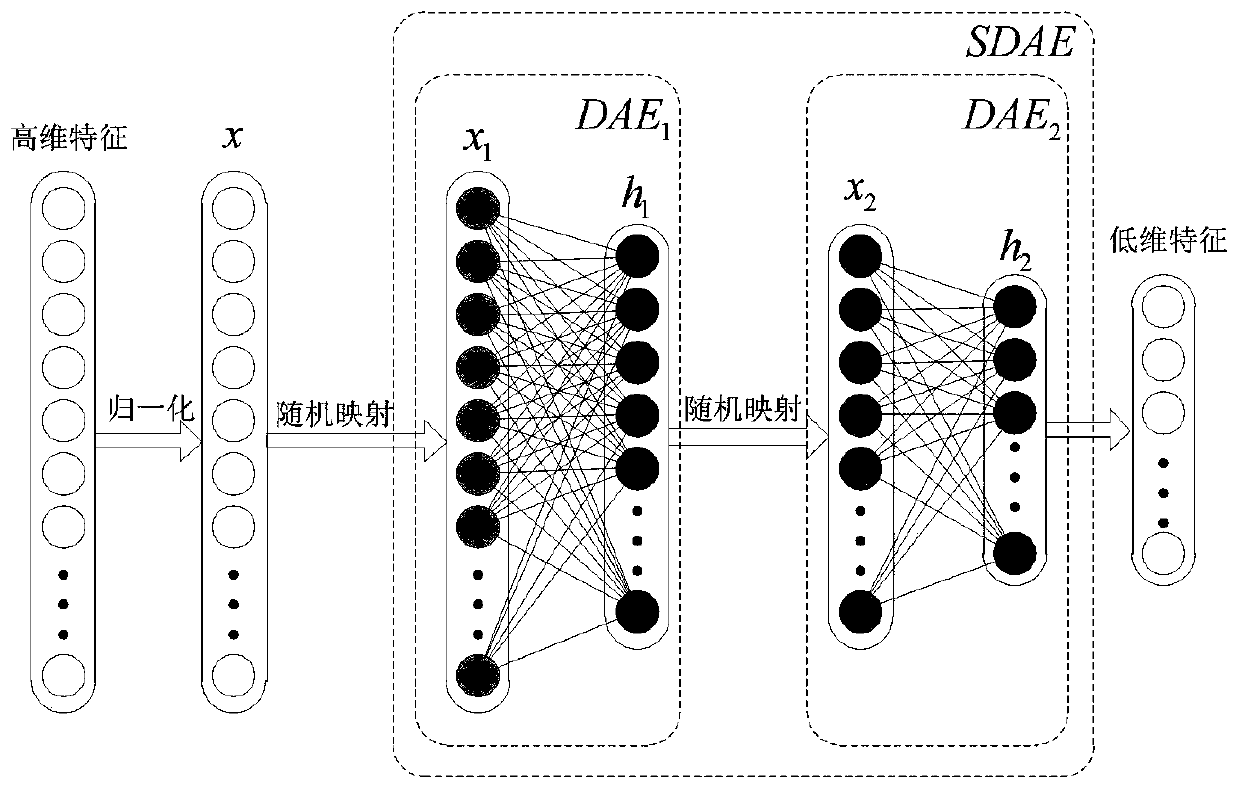

[0059] The collected raw sensing signals are preprocessed and the time domain, frequency domain and time-frequency domain features of each signal are extracted respectively. Time domain features include: mean, peak, peak-to-peak, rms, slope, kurtosis, kurtosis f...

Embodiment 2

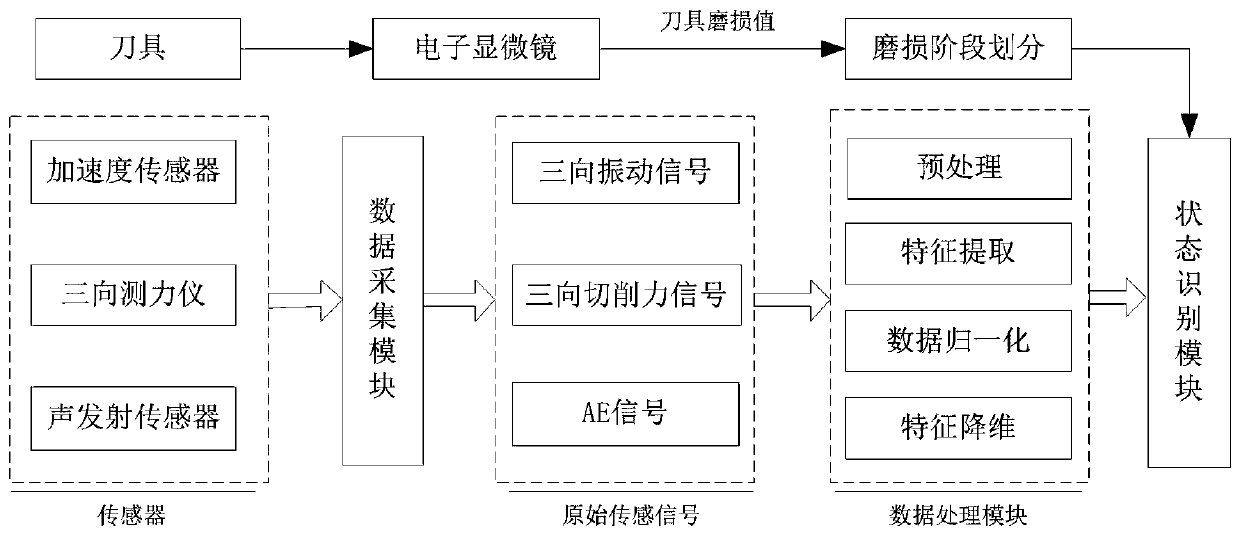

[0083] Such as image 3 As shown, a system for realizing the tool monitoring method of high-speed milling process adaptive to working conditions, including:

[0084] Acceleration sensor for monitoring and sending three-way vibration signals under different milling conditions (measuring x, y, z three-way vibration signals);

[0085] Three-way dynamometer for monitoring and sending three-way cutting force signals under different milling conditions;

[0086] Acoustic emission sensors for monitoring and sending unidirectional acoustic emission signals under different milling conditions;

[0087] The data acquisition module is used to collect three-way vibration signals, three-way cutting force signals and one-way acoustic emission signals under different milling conditions;

[0088] Electron microscope, used to measure the actual wear of the tool;

[0089] Data processing module for signal preprocessing, feature extraction and related processing;

[0090] The state identificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com