Forming method and forming tooling of a composite material c-shaped beam

A composite material and molding method technology, applied to household appliances, other household appliances, household components, etc., can solve problems such as unfavorable manufacturing efficiency and manufacturing accuracy, influence of C-beam molding quality, easy generation of wrinkles and bending, etc. Improve the curing effect, simplify the molding difficulty, and improve the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

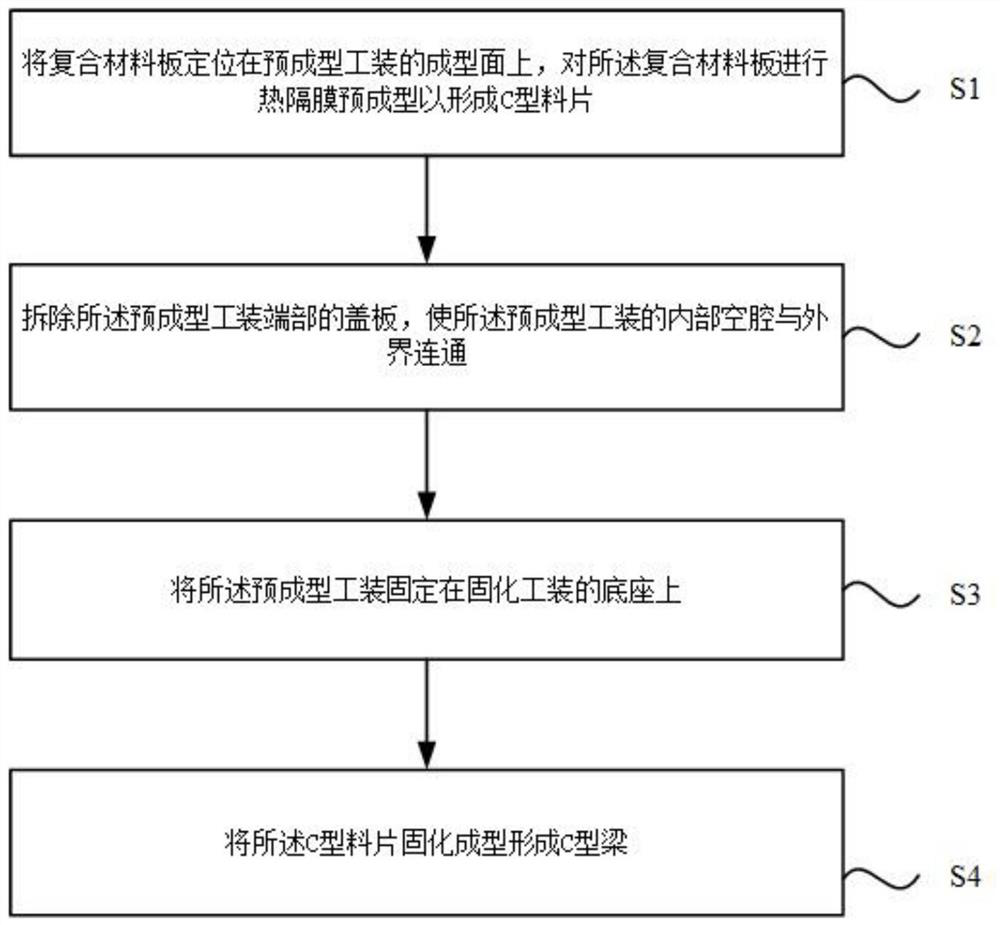

[0039] This embodiment provides a method for forming a composite C-beam. By using this forming method, the composite material plate 1 can be made into a C-beam required on aircraft and other equipment. The C-beam has a "C"-shaped structure as a whole. It includes a top plate and two side plates protruding from both ends of the top plate. Specifically, such as figure 1 As shown, the molding method specifically includes the following steps:

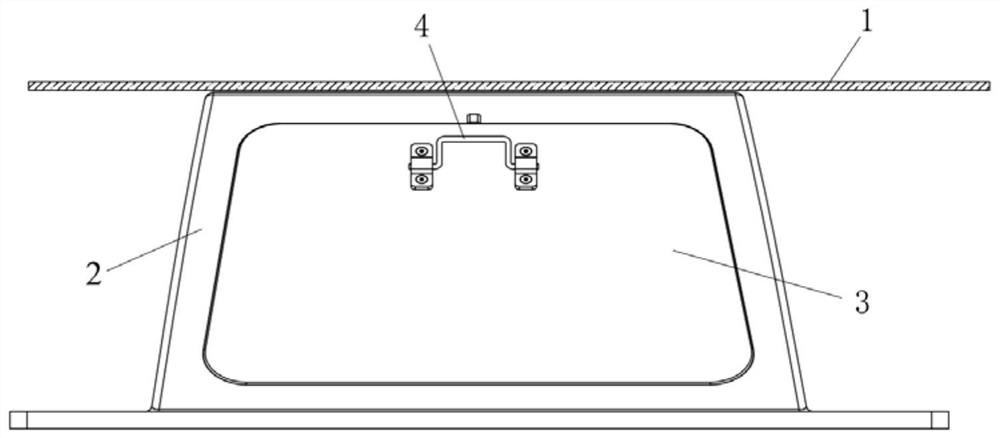

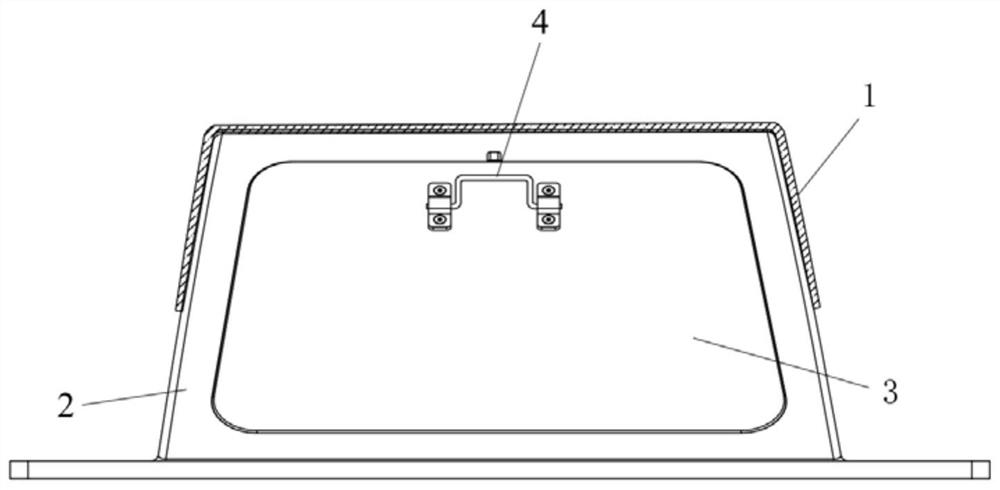

[0040] S1. Positioning the composite material plate 1 on the forming surface of the preforming tooling 2, performing thermal diaphragm preforming on the composite material plate 1 to form a C-shaped blank;

[0041] S2. Remove the cover plate 3 at the end of the preforming tooling 2, so that the internal cavity 201 of the preforming tooling 2 communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com