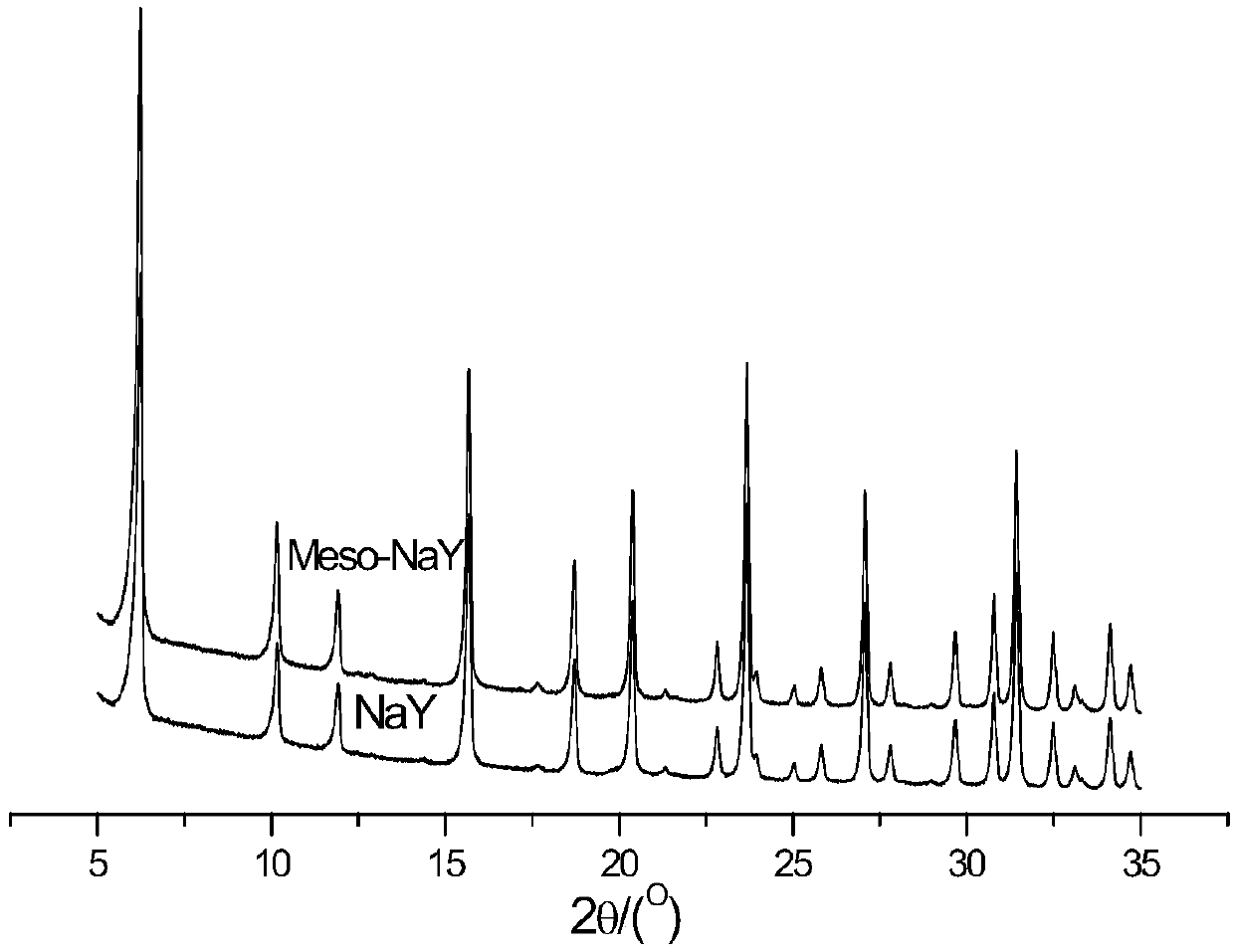

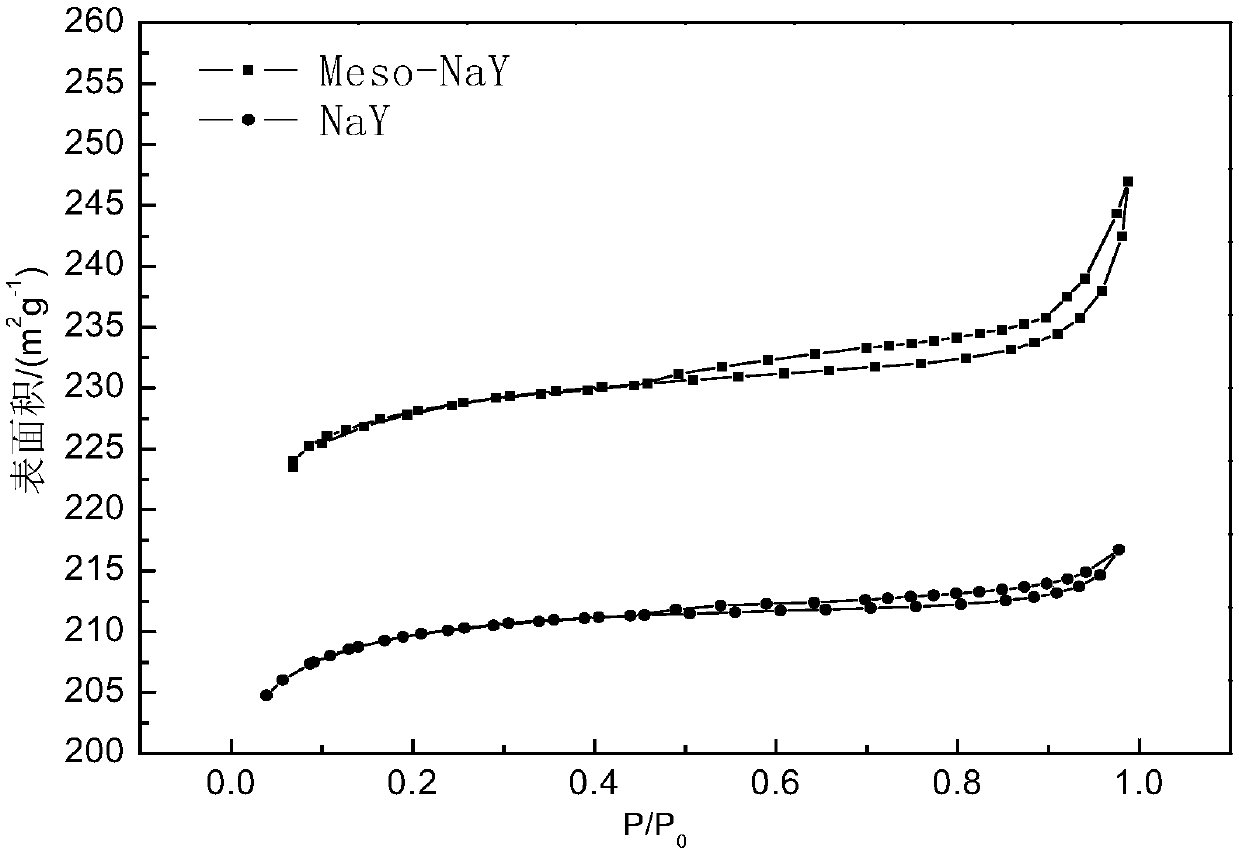

Preparation method of mesopore-containing high-crystallinity Y-type molecular sieve

A technology of molecular sieve and crystallization directing agent, applied in molecular sieve and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problem of limited improvement in acidity and hydrothermal stability, and can not reach FCC use requirements, etc., to achieve the effect of obvious mesoporous characteristics, simple preparation method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the high-crystallinity Y-type molecular sieve containing mesopore provided by the present invention is characterized in that it is characterized in that the preparation method comprises:

[0019] Preparation of crystallization directing agent: according to Al 2 o 3 :(1~35)SiO2 2 :(10~35)Na 2 O:(180~400)H 2 The molar ratio of O is to mix silicon source, aluminum source and water, and then carry out static aging at 0-80°C to obtain a crystallization directing agent;

[0020] The cationic starch template modified by 2,3-epoxypropyltrimethylammonium chloride with a degree of substitution of 0.01% to 10%, alkali source and water according to the mass ratio of cationic starch template, alkali source and water is (0.1~5):(0.1~3):(1~100) mixed, then hydrolyzed at 30~150℃ to obtain hydrolyzate;

[0021] According to Al 2 o 3 :(1~20)SiO2 2 :(1~10)Na 2 O:(120~300)H 2 Molar ratio of O, the crystallization directing agent, silicon source, aluminum...

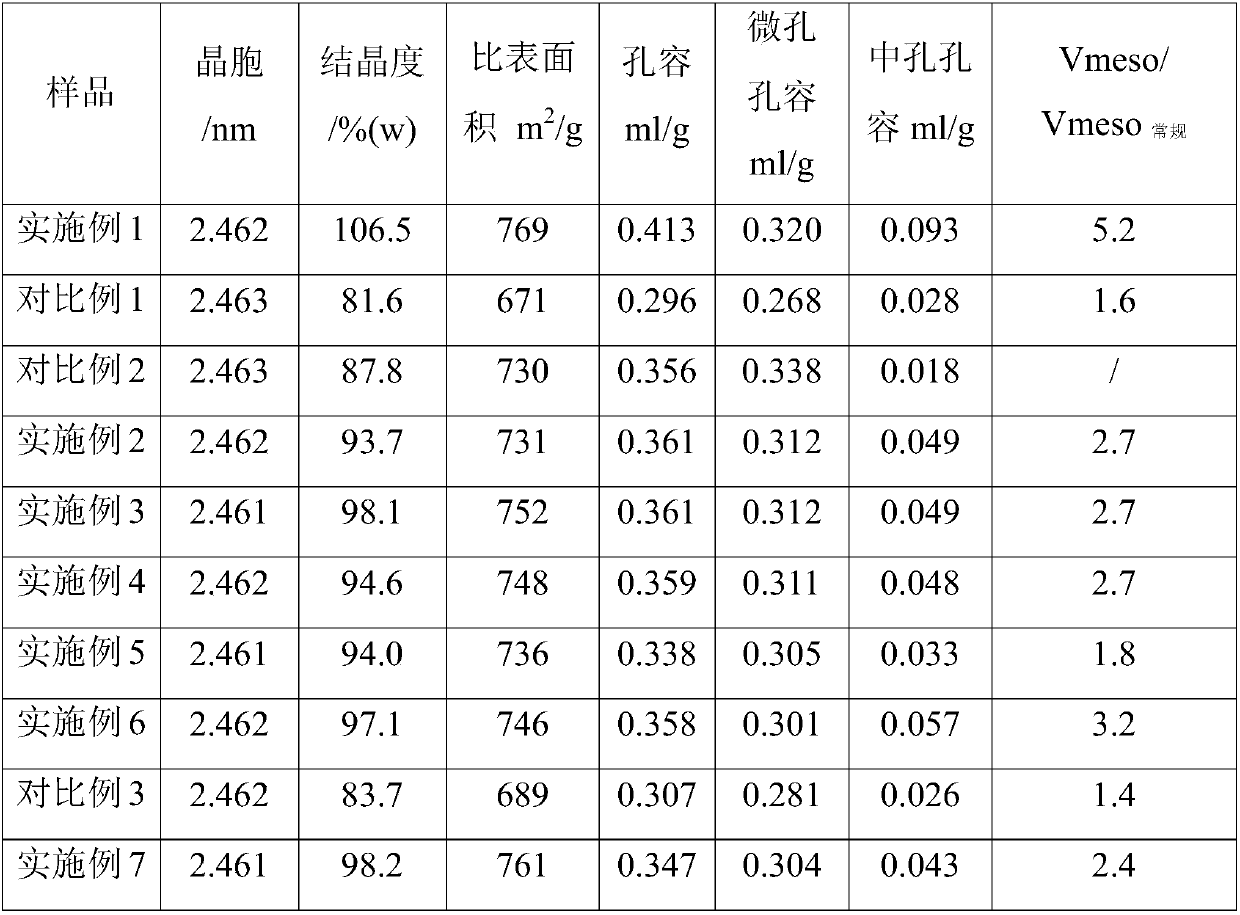

Embodiment 1

[0037] According to Al 2 o 3 :15SiO2 2 :16.5Na 2 O:320H 2 O molar ratio, 30ml of water glass (modulus 3.3) was added to 20.8ml of sodium metaaluminate solution, stirred to dissolve, and then aged at 45°C for 5h to obtain a crystallization director.

[0038] Take 2g of YZA-2 cationic starch (2,3-epoxypropyltrimethylammonium chloride substitution degree 0.5%) in 60g of water, add 1g of NaOH, stir evenly, heat up to 60°C, stir at constant temperature for 1h for hydrolysis treatment.

[0039] Then add the above 18g of directing agent to 65ml of water glass (modulus 3.3), stir for 0.5h, then add the YZA-2 cationic starch aqueous solution after the above hydrolysis treatment, stir for 1h, then add 40ml of aluminum sulfate and 18ml of sodium metaaluminate After the addition, continue to stir for 1h, and finally put the mixture into a stainless steel crystallization kettle, seal it and place it in a 95°C oven for 28h to crystallize, then filter, wash, and dry the filter cake in a ...

Embodiment 2

[0056] According to Al 2 o 3 :15SiO2 2 :16.5Na 2 O:320H 2 O molar ratio, 30ml of water glass (modulus 3.3) was added to 20.8ml of sodium metaaluminate solution, stirred to dissolve, and then aged at 30°C for 20 hours to obtain a crystallization directing agent.

[0057] Take 1g of YZA-1 cationic starch (2,3-epoxypropyltrimethylammonium chloride substitution degree 1%), put it in 60g of water, add 0.5g of NaOH, stir evenly, heat up to 40°C, stir at constant temperature for 1h to hydrolyze deal with.

[0058] Then add the above 12g of directing agent to 50ml of water glass (modulus 3.3), stir for 0.5h, then add the YZA-1 cationic starch aqueous solution after the above hydrolysis treatment, stir for 1h, then add 30ml of aluminum sulfate and 10ml of sodium metaaluminate After the addition, continue to stir for 1h, and finally put the mixture into a stainless steel crystallization kettle, seal it and put it in a 90°C oven for 30h to crystallize, then filter, wash, and dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com