Method for separating polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and formaldehyde, applied in chemical instruments and methods, preparation of organic compounds, sustainable manufacturing/processing, etc., can solve problems such as pipeline blockage, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

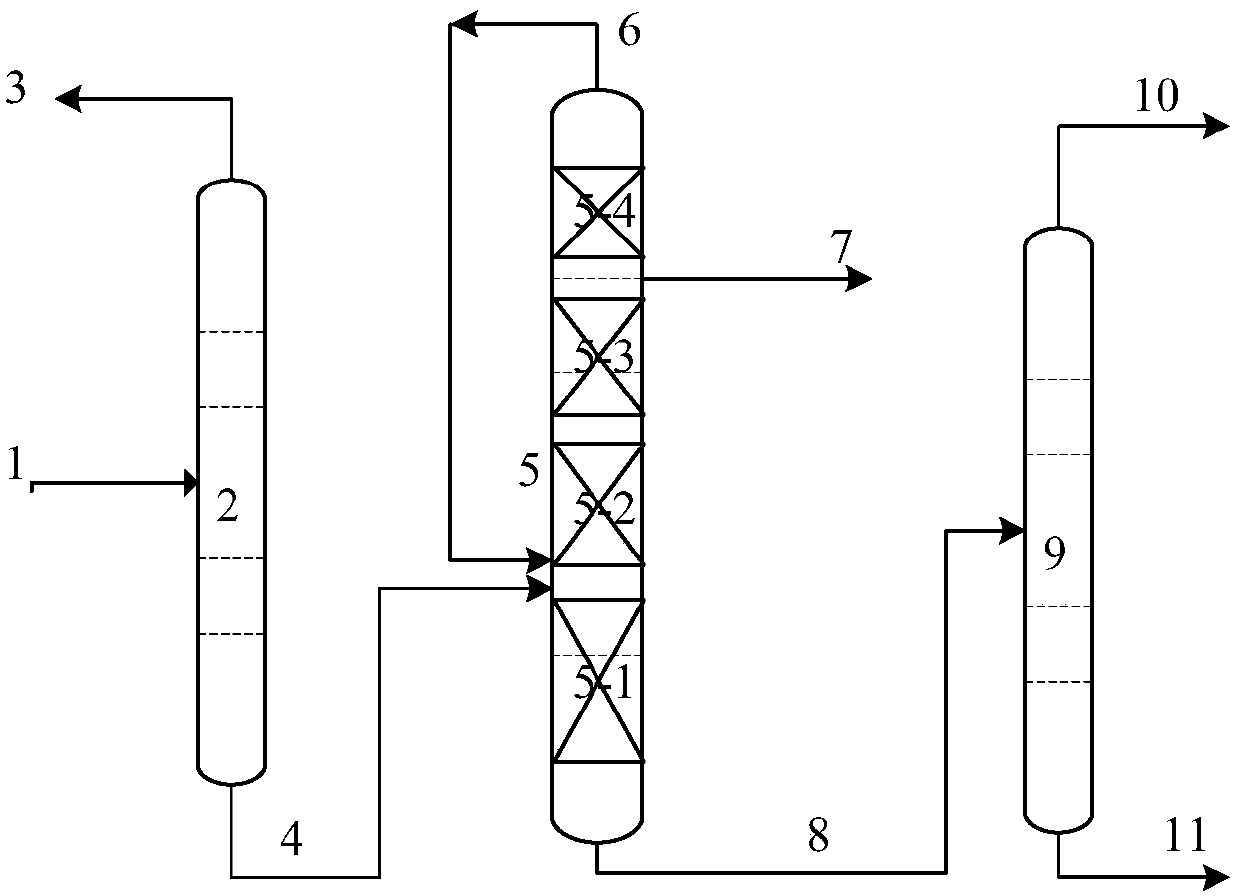

Embodiment 1

[0033] The reaction mixture from the synthesis reaction unit first enters the first rectification tower as the material to be separated. The first rectification tower has a total of 30 theoretical plates, the operating pressure is normal pressure, and the top temperature of the tower is 40.7 ° C. Components, the temperature of the tower bottom is 102 ℃ to obtain the first tower bottom liquid; the first tower bottom liquid enters the catalytic rectification tower containing four sections of packing, and the catalytic rectification tower has 60 theoretical plates in total, and the operating pressure is normal pressure. The kettle temperature is 168°C; the stripping section has a total of 15 theoretical plates, and the temperature is 120°C; the second section has a total of 15 theoretical plates, and the operating temperature is 95°C. Packing: There are 20 theoretical plates in the third section, filled with packing containing sulfonic acid type cation exchange resin catalyst, and...

Embodiment 2

[0041] The reaction mixture from the synthesis reaction unit first enters the first rectification tower as the material to be separated. The first rectification tower has a total of 30 theoretical plates, the operating pressure is normal pressure, and the top temperature of the tower is 40.7 ° C. Components, the temperature of the tower bottom is 102 ℃ to obtain the first tower bottom liquid; the first tower bottom liquid enters the catalytic rectification tower containing four sections of packing, and the catalytic rectification tower has 60 theoretical plates in total, and the operating pressure is normal pressure. The kettle temperature is 168°C; the stripping section has a total of 15 theoretical plates, and the temperature is 120°C; the second section has a total of 15 theoretical plates, and the operating temperature is 95°C, filled with packing containing HZSM-5 molecular sieve catalyst; The third section has a total of 20 theoretical plates, filled with fillers containi...

Embodiment 3

[0045] The reaction mixture from the synthesis reaction unit first enters the first rectification tower as the material to be separated. The first rectification tower has 20 theoretical plates in total, the operating pressure is normal pressure, and the temperature at the top of the tower is 40.7°C to obtain the first light Components, the temperature of the tower bottom is 104 ℃ to obtain the first tower bottom liquid; the first tower bottom liquid enters the catalytic rectification tower containing four sections of packing, the catalytic rectification tower has a total of 70 theoretical plates, and the operating pressure is 0.2MPa. The kettle temperature is 204°C; the stripping section has a total of 10 theoretical plates, and the temperature is 140°C; the second section has a total of 20 theoretical plates, and the operating temperature is 117°C, and the internal filling contains modified sulfonic acid type cation exchange resin Catalyst packing; the third section has a tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com