Solar cell and preparation method therefor

A solar cell, N-type technology, applied in the field of solar cells, can solve the problems of reduced photoelectric conversion efficiency of organic-inorganic hybrid solar cells, poor film formation quality of organic material layers, low photoelectric conversion efficiency of solar cells, etc. Conversion efficiency, improved quality, improved transmission path effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

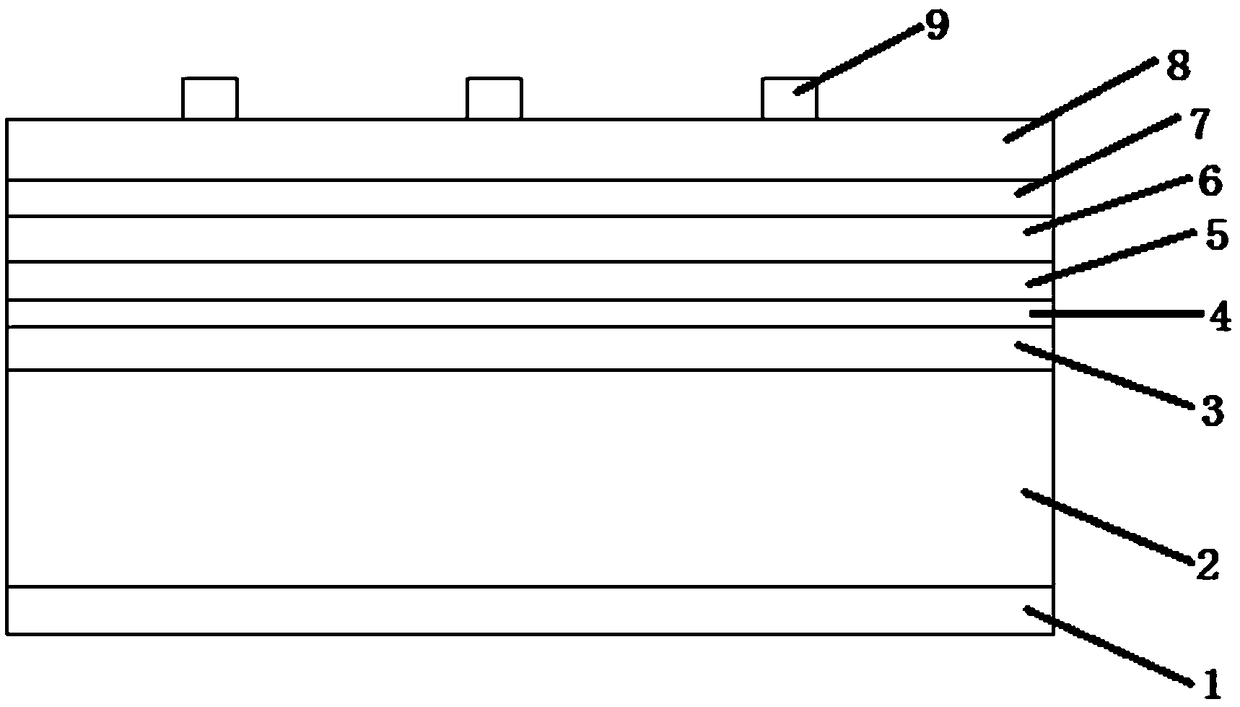

Image

Examples

preparation example Construction

[0026] A kind of preparation method of solar cell that the present invention proposes, comprises the following steps:

[0027] 1) Provide N-type monocrystalline silicon wafers, carry out texturing treatment to the N-type monocrystalline silicon wafers, and form a pyramid-structured textured layer on the upper surface of the N-type monocrystalline silicon wafers;

[0028] 2) Depositing an N-type amorphous silicon layer on the upper surface of the N-type single crystal silicon wafer, and then converting the N-type amorphous silicon layer into an N-type polysilicon layer through heat treatment, wherein the doping concentration of the N-type polysilicon layer is less than The doping concentration of the N-type monocrystalline silicon wafer, specifically, the heat treatment temperature is 600-800°C, the heat treatment time is 20-40 minutes, and the thickness of the N-type polysilicon layer is 20-30 nanometers;

[0029] 3) depositing an inorganic insulating thin layer on the surface...

Embodiment 1

[0039] A method for preparing a solar cell, comprising the steps of:

[0040] 1) Provide N-type monocrystalline silicon wafers, carry out texturing treatment to the N-type monocrystalline silicon wafers, and form a pyramid-structured textured layer on the upper surface of the N-type monocrystalline silicon wafers;

[0041] 2) Depositing an N-type amorphous silicon layer on the upper surface of the N-type monocrystalline silicon wafer, and then converting the N-type amorphous silicon layer into an N-type polysilicon layer through heat treatment, wherein the doping concentration of the N-type polysilicon layer is less than The doping concentration of the N-type monocrystalline silicon wafer, specifically, the heat treatment temperature is 700°C, the heat treatment time is 30 minutes, and the thickness of the N-type polysilicon layer is 25 nanometers;

[0042] 3) depositing an inorganic insulating thin layer on the surface of the N-type polysilicon layer, the thickness of the ino...

Embodiment 2

[0052] A method for preparing a solar cell, comprising the steps of:

[0053] 1) Provide N-type monocrystalline silicon wafers, carry out texturing treatment to the N-type monocrystalline silicon wafers, and form a pyramid-structured textured layer on the upper surface of the N-type monocrystalline silicon wafers;

[0054] 2) Depositing an N-type amorphous silicon layer on the upper surface of the N-type monocrystalline silicon wafer, and then converting the N-type amorphous silicon layer into an N-type polysilicon layer through heat treatment, wherein the doping concentration of the N-type polysilicon layer is less than The doping concentration of the N-type monocrystalline silicon wafer, specifically, the heat treatment temperature is 600°C, the heat treatment time is 40 minutes, and the thickness of the N-type polysilicon layer is 30 nanometers;

[0055] 3) depositing an inorganic insulating thin layer on the surface of the N-type polysilicon layer, the thickness of the ino...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com