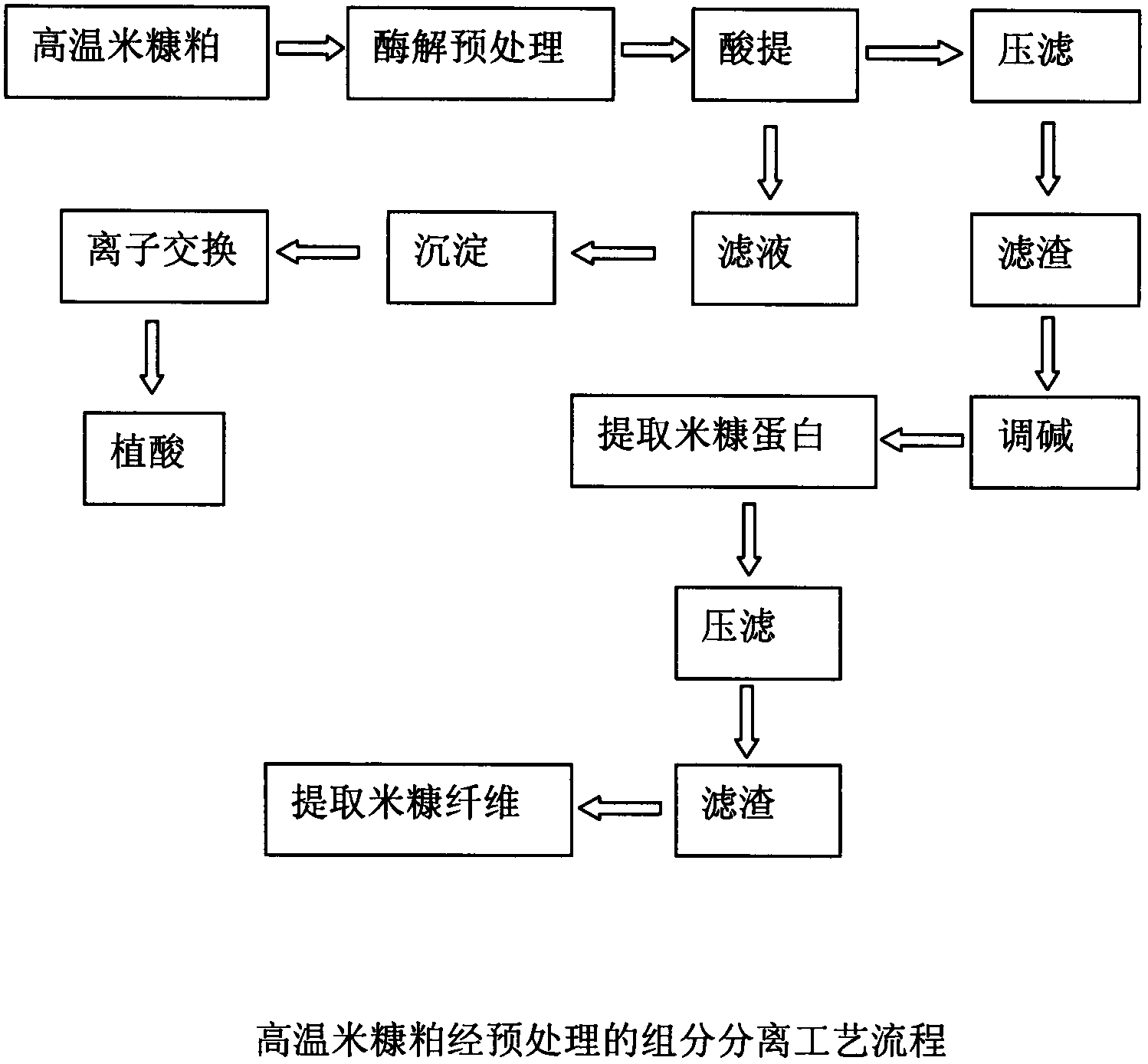

Industrialized pretreatment method of high-temperature rice bran meal

A technology for rice bran meal and rice bran, which is applied in the field of pre-industrialization of high-temperature rice bran meal, can solve problems such as difficulty in filtration, and achieve the effect of ensuring continuity and good filtration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

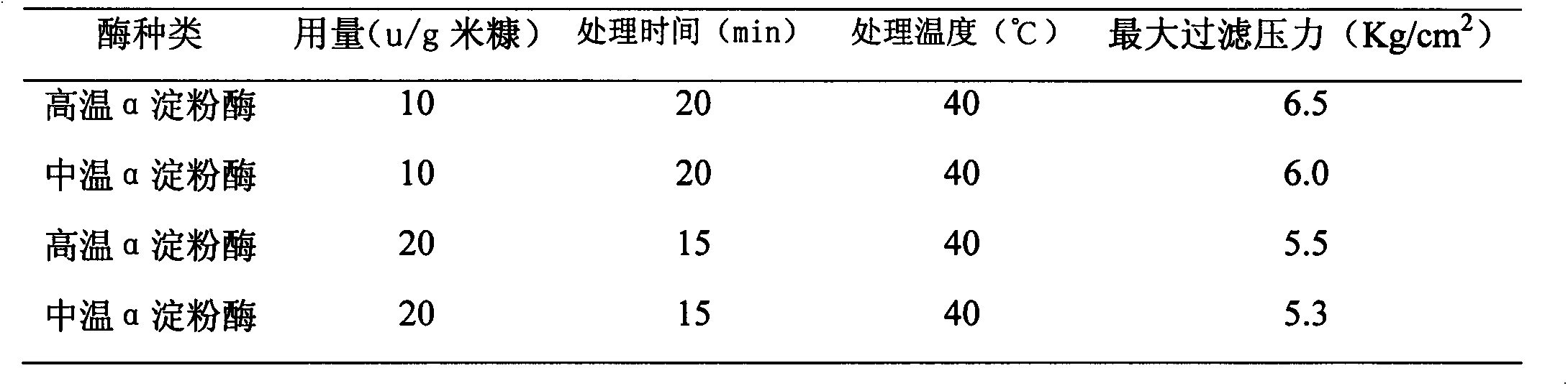

Embodiment 1

[0018] Example 1: Take 100Kg of high-temperature rice bran dregs, adjust the slurry according to the concentration of 1:8 (w / v), add 100mL of high-temperature α-amylase (20,000U / mL) and mix evenly. After the slurry is adjusted, steam is directly heated to 40 ℃, stirred at 100rpm for 15 minutes, pumped into the extraction tank with a thick slurry pump, adjusted pH 2.0 with HCl, extracted and separated phytate, separated with a filter press after extraction, and sent the filter residue to the extraction tank with an auger. Extract protein or dietary fiber after pH adjustment.

Embodiment 2

[0019] Example 2: Take 100Kg of high-temperature rice bran meal, adjust the slurry according to the concentration of 1:10 (w / v), add 50mL of medium-temperature α-amylase (20,000U / mL) and mix evenly. After the slurry is adjusted, steam is directly heated to 40 ℃, stirred at 100rpm for 20min, pumped into the extraction tank with thick slurry pump, adjusted pH 2.0 with HCl, extracted and separated phytate, separated with filter press after extraction, and sent the filter residue to the extraction tank with an auger. Extract protein or dietary fiber after pH adjustment.

Embodiment 3

[0020] Example 3: Take 100Kg of high-temperature rice bran dregs, adjust the slurry according to the concentration of 1:8 (w / v), add 50mL of high-temperature α-amylase (20,000U / mL) and mix evenly. After the slurry is adjusted, steam is directly heated to 40 ℃, stirred at 100rpm for 20min, pumped into the extraction tank with thick slurry pump, adjusted pH 2.0 with HCl, extracted and separated phytate, separated with filter press after extraction, and sent the filter residue to the extraction tank with an auger. Extract protein or dietary fiber after pH adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com