TPE material and preparation method thereof

A technology of raw materials and cross-linking agents, applied in the field of materials, can solve the problems of demanding material fluidity, etc., and achieve the effects of absorbing unpleasant odors, reducing precipitation, and avoiding exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

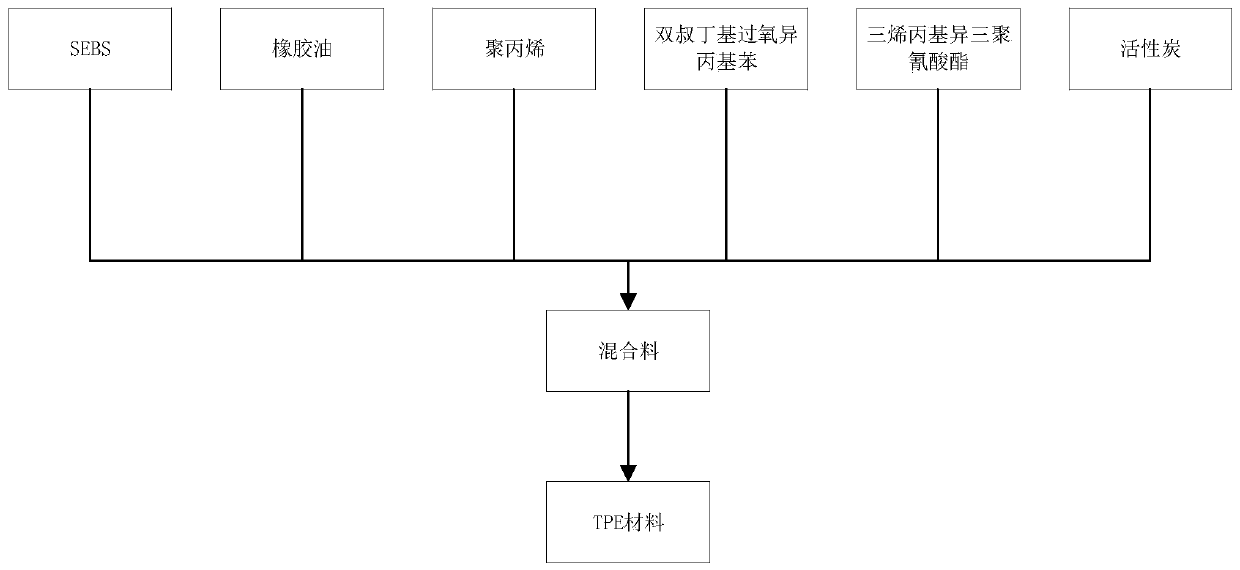

Method used

Image

Examples

Embodiment 1

[0036] Take by weighing 10kg SEBS, 12kg rubber oil, 10kg polypropylene, 0.1kg bis-tert-butylperoxycumene, 0.1kg triallyl isocyanurate and 0.2kg active carbon and add them into a mixer and stir well to obtain The mixture is put into the extruder and thermally cut into pellets to obtain the TPE material.

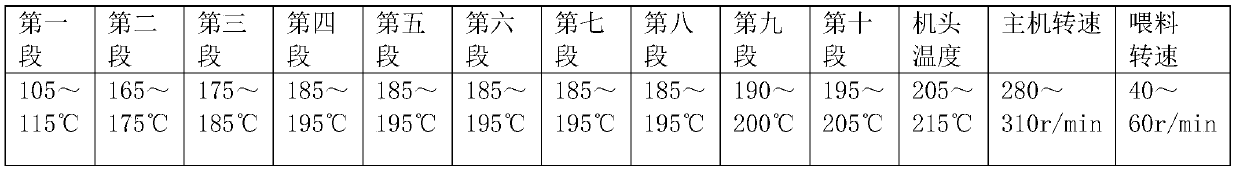

[0037] The temperature and rotational speed settings of the extruder are shown in Table 2.

[0038] Table 2: Temperature and rotational speed settings of the extruder in Example 1

[0039]

[0040] In Example 1, every 0.1 kg is one portion.

Embodiment 2

[0045] Take by weighing 12kg SEBS, 13kg rubber oil, 12kg polypropylene, 0.12kg bis-tert-butylperoxycumene, 0.08kg triallyl isocyanurate and 0.15kg active carbon and add in the mixer and stir well to obtain The mixture is put into the extruder and thermally cut into pellets to obtain the TPE material.

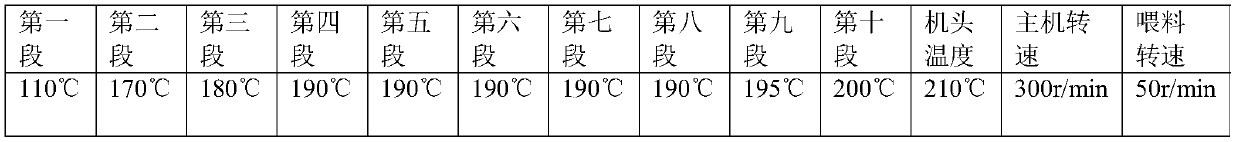

[0046] The temperature and rotational speed settings of the extruder are shown in Table 3.

[0047] Table 3: Temperature and rotational speed settings of the extruder in Example 2

[0048]

[0049] In Example 2, every 0.1 kg is one portion.

Embodiment 3

[0051] Weigh 14.5kg SEBS, 15kg rubber oil, 14kg polypropylene, 0.13kg bis-tert-butylperoxycumene, 0.14kg triallyl isocyanurate and 0.25kg activated carbon and add them into the mixer and stir them evenly. The mixture is obtained, and the mixture is put into an extruder and thermally cut into pellets to obtain a TPE material.

[0052] The temperature and rotational speed settings of the extruder are shown in Table 4.

[0053] Table 4: Temperature and rotational speed settings of the extruder in Example 3

[0054]

[0055] In embodiment 3, every 0.1kg is one portion.

[0056] The properties of the TPE materials prepared in Examples 1-3 are shown in Table 5.

[0057] Table 5: Properties of TPE materials prepared in Example 1-Example 3

[0058] performance Example 1 Example 2 Example 3 Hardness shoreA 40 40 40 100% body strength MPa 1.5 1.8 1.6 200% body strength MPa 2.6 3.0 2.8 Tensile strength MPa 11.5 12 12.5 Permanent ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap