Dome structural system of longspan fabricated prestressed ridge rod supporting rope

A prestressed, prefabricated technology, applied in the dome roof structure, arched structure, roof, etc., to achieve the effect of reducing construction cost, easy installation and tensioning, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

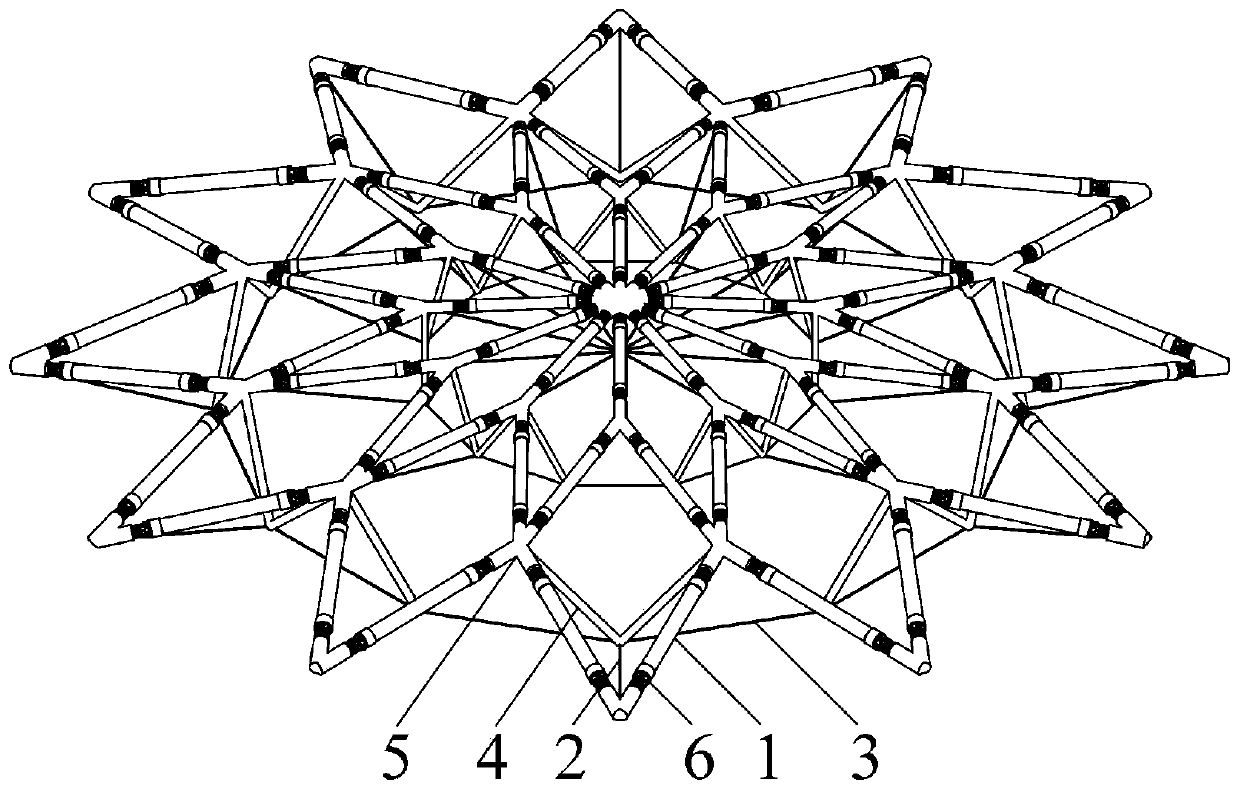

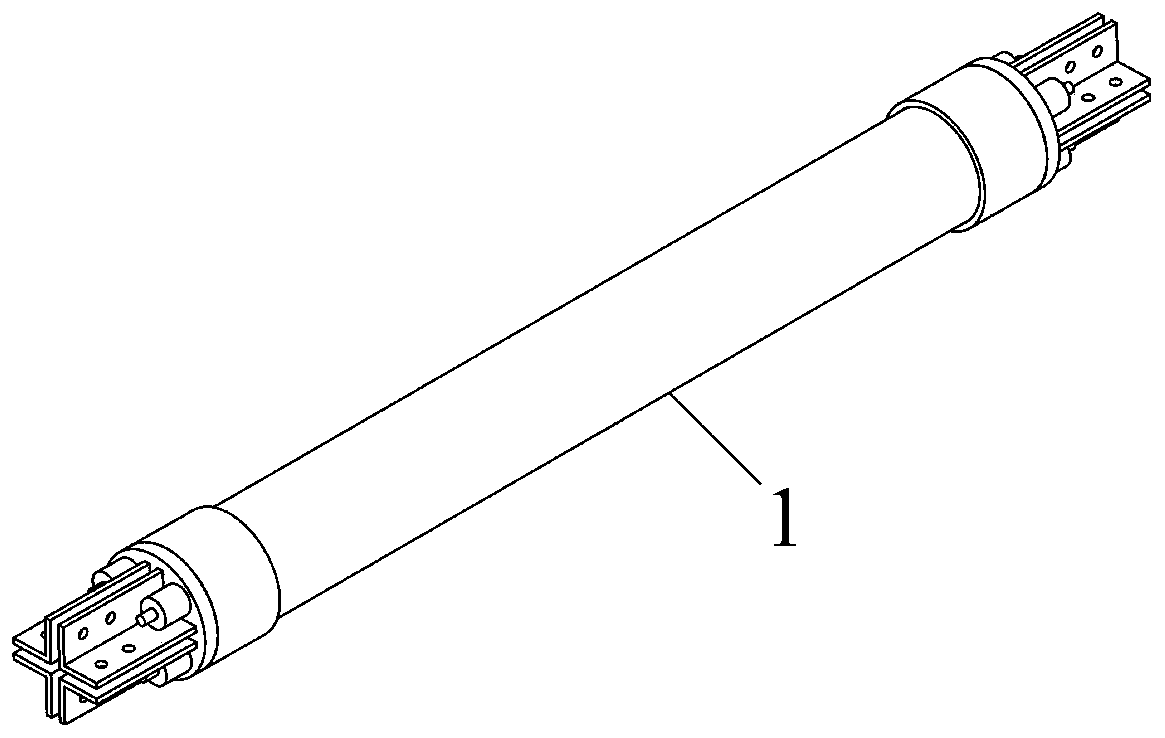

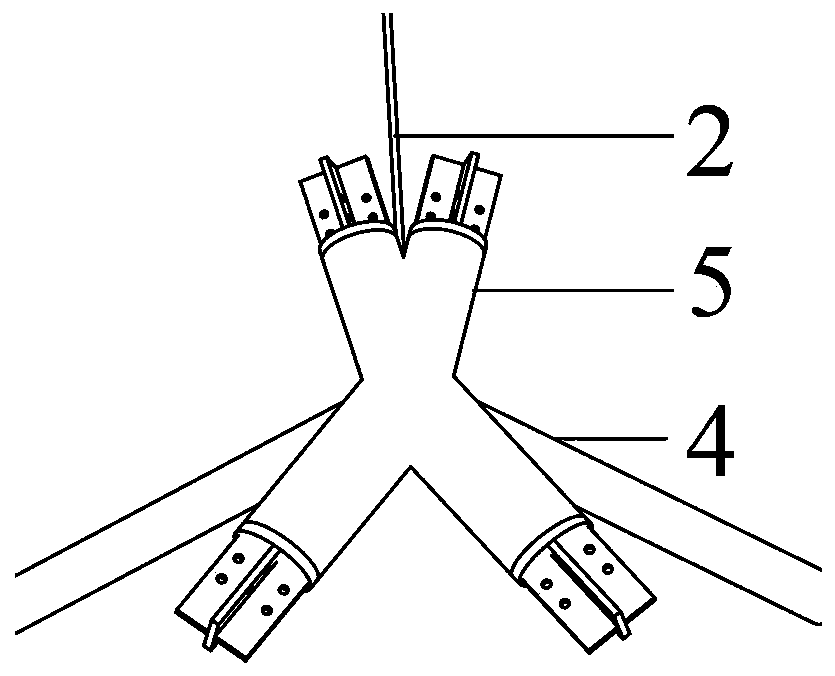

[0025] Combine below Figure 1-Figure 8 The specific implementation of the large-span assembled prestressed ridge-rod ring-supported cable dome structure system is described. The design, assembly and construction steps of the structure system are as follows:

[0026] 1) Structural design steps:

[0027] (1) Determine the geometric topological form of the structural system, the structural form of the edge ring beam and the corresponding support constraints according to the structural design requirements;

[0028] (2) According to the structural design load requirements, determine the preliminary design dimensions of the prestressed ridge bar, hoop support bar, central compression bar, hoop cable and oblique cable;

[0029] (3) Carry out the form-finding and force-finding analysis of the structural system according to the design geometric topological form of the structural system, and determine the initial geometric form of the construction state and the construction method tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com