Equipment, system and method for automatically detecting characteristics of fire-fighting water pump as well as terminal

A technology for automatic detection of pump characteristics, applied in mechanical equipment, pump control, non-variable pumps, etc., can solve the problems of slow manual valve opening adjustment, waste of manpower and material resources, and difficult control, so as to reduce testing costs, The effect of improving efficiency, convenient storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

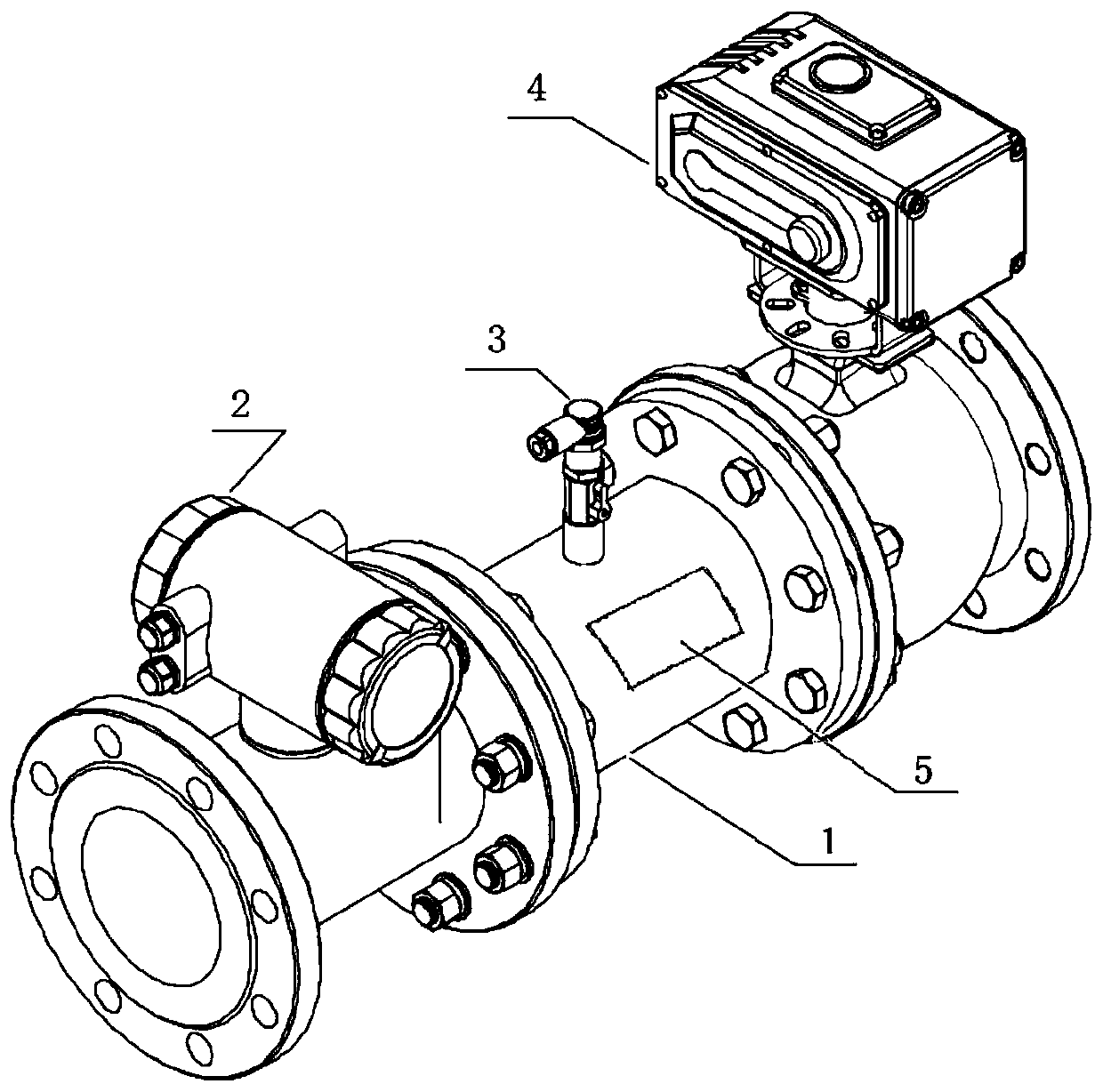

[0062] Such as figure 1 As shown, the automatic equipment for fire pump characteristic detection provided by the first embodiment includes: pipeline 1, flow sensor 2, pressure sensor 3, electric valve 4, signal transmitting device and controller.

[0063] Wherein, the flow sensor 2 and the pressure sensor 3 are respectively arranged on the pipeline 1, and the flow sensor 2 and the pressure sensor 3 are respectively electrically connected to the controller. Among them, the flow sensor 2 is used to obtain the flow value in the pipeline 1 , and the pressure sensor 3 is used to obtain the pressure value in the pipeline 11 . It should be noted that both the flow sensor 2 and the pressure sensor 3 are prior art.

[0064] The electric valve 4 is arranged at the outlet of the pipeline 1, and the electric valve 4 is electrically connected with the controller. It should be noted that the electric valve 4 is used to control the opening of the pipeline 1 .

[0065] The signal transmitt...

Embodiment 2

[0076] The detection system for fire pump characteristics provided by Embodiment 2 includes: a remote terminal and any one of the automation equipment in claims 1 to 3.

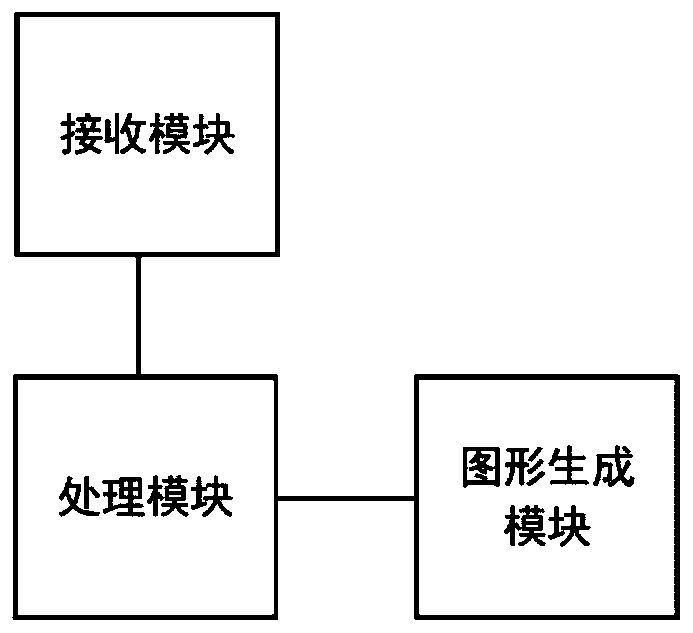

[0077] Such as figure 2 As shown, the remote terminal includes: a receiving module, a processing module and a graphics generating module.

[0078] Wherein, the receiving module and the graphics generating module are respectively electrically connected to the processing module. The receiving module is used to receive the signal sent by the signal transmitting device. It should be noted that the receiving module is an existing technology, and is matched with the signal transmitting module in the automatic equipment for fire pump characteristic detection. For example, when the signal transmitting device is a Bluetooth transmitting device, the signal receiving module is a Bluetooth receiving module.

[0079] Wherein, the processing module is used for generating graphic signals according to the flow value and ...

Embodiment 3

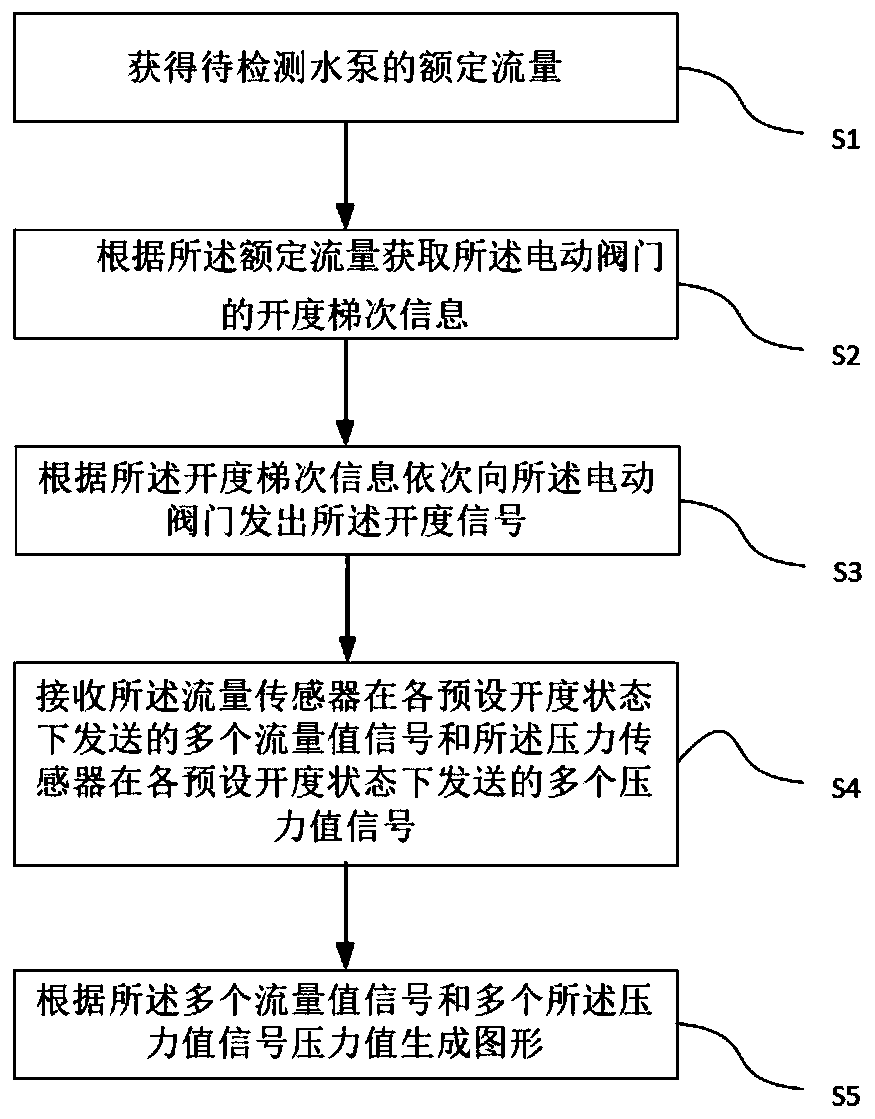

[0088] The fire pump characteristic automatic detection method provided by the third embodiment is applied in the system as claimed in claim 4, such as image 3 shown, including the following steps:

[0089] S1. Obtain the rated flow rate of the water pump to be tested. It should be noted that the rated flow rate of the water pump to be tested is generally marked on the nameplate.

[0090] S2. Obtain the opening degree information of the electric valve according to the rated flow rate; wherein, the opening degree information includes a group of opening degree signals. A possible opening step information includes: 10%, 30%, 50%, 70%, 80% and 95%. Among them, 10%, 30%, 50%, 70%, 80% and 95% refer to the opening value of the electric valve. It should be noted that the opening signal of the opening step information is related to the specific parameters of the electric valve used.

[0091] S3. Sending opening degree signals to the electric valve sequentially according to the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com