Device and method for detecting load of mining dump truck for strip mine

A technology of dump trucks and detection devices, which is applied in the direction of measuring devices, weighing equipment testing/calibration, special scales, etc., can solve problems such as complexity, high cost, and unstable ore density, and achieve novel structure, wide applicability, The effect of weakening the orthogonal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

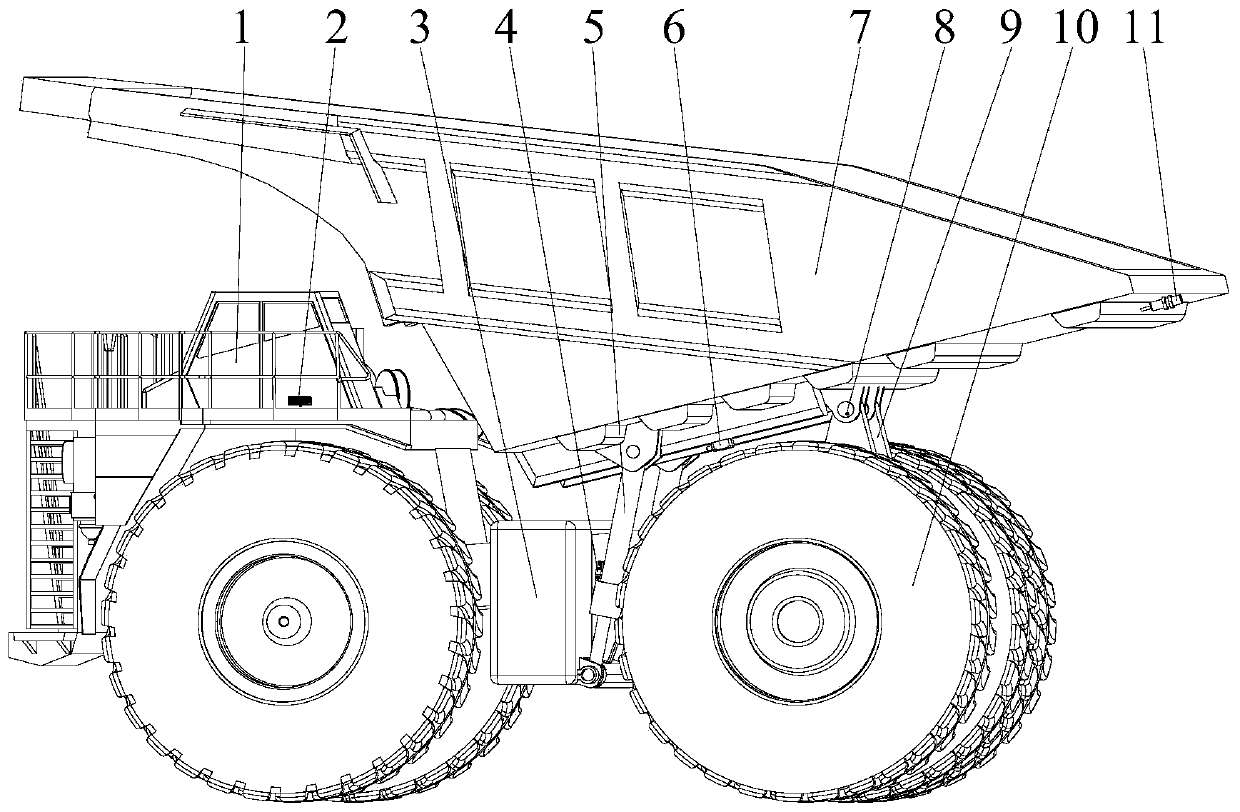

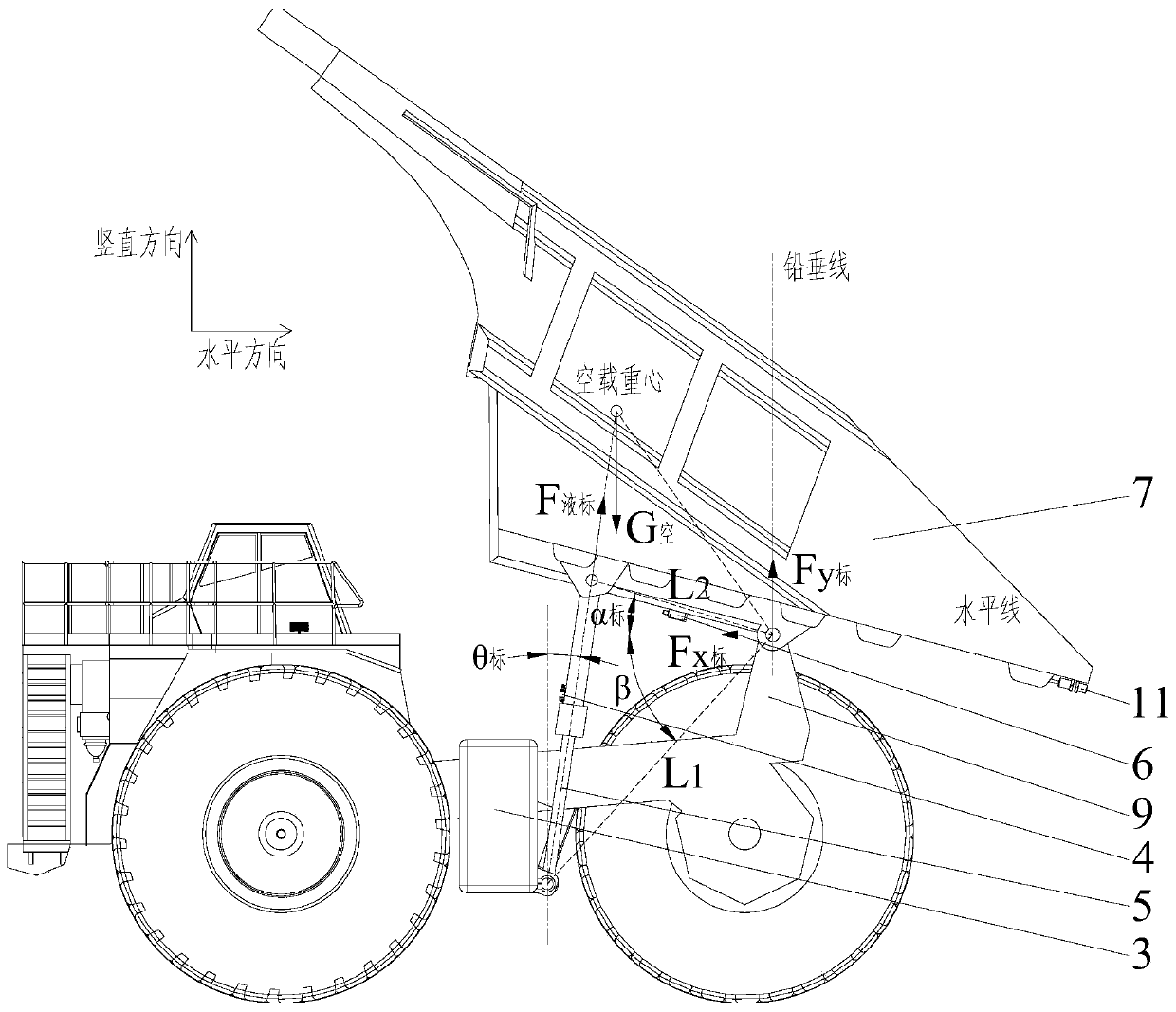

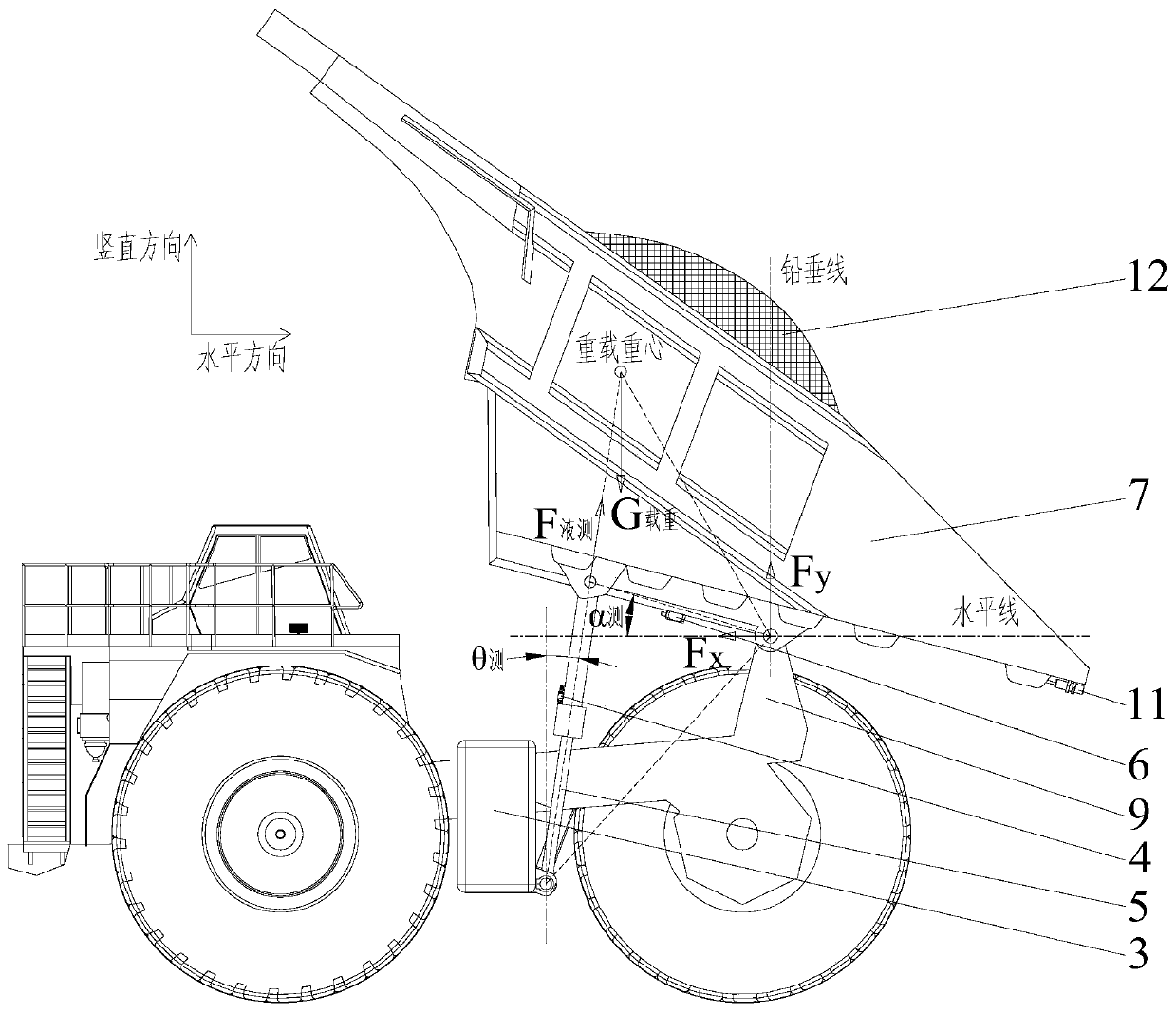

[0043] Such as Figure 1 ~ Figure 3 As shown, the present invention discloses a dump truck for open-pit mining, comprising: a car body; a compartment arranged on the car body, the bottom rear end of the compartment is hinged to the rear axle 9 on the car body through a hinge pin , the front end of the bottom of the compartment is connected to the vehicle body through a lifting hydraulic cylinder, which is characterized in that it also includes:

[0044]Oil pressure sensor 4, pin shaft load cell 8, inclination sensor 6, ultrasonic proximity switch 11 and industrial computer 2, wherein, described oil pressure sensor 4 is arranged on the cylinder liner of lifting hydraulic cylinder 5, is used for detecting lifting hydraulic pressure The supporting force of the cylinder 5 to the carriage 7;

[0045] The inclination sensor 6 is arranged on the bottom plane of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com