Method for quickly detecting residual principal stress of polymer material products

A polymer material and principal stress technology, which is used in material analysis using radiation diffraction, measuring devices, force/torque/work measuring instruments, etc. It can solve the problems of sample center offset, calculation result error, etc., and achieve accurate measurement results. , the effect of short data collection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The polymer material product adopted in this embodiment is polyethylene (brand name is TR480M). The polyethylene pellets were injection-molded on a Haitian MA900 injection machine into a diaphragm with a size of 60mm×60mm×2mm. The screw is divided into 5 sections, the temperature is 180°C, 180°C, 170°C, 160°C, 150°C respectively, and the mold temperature is 40°C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

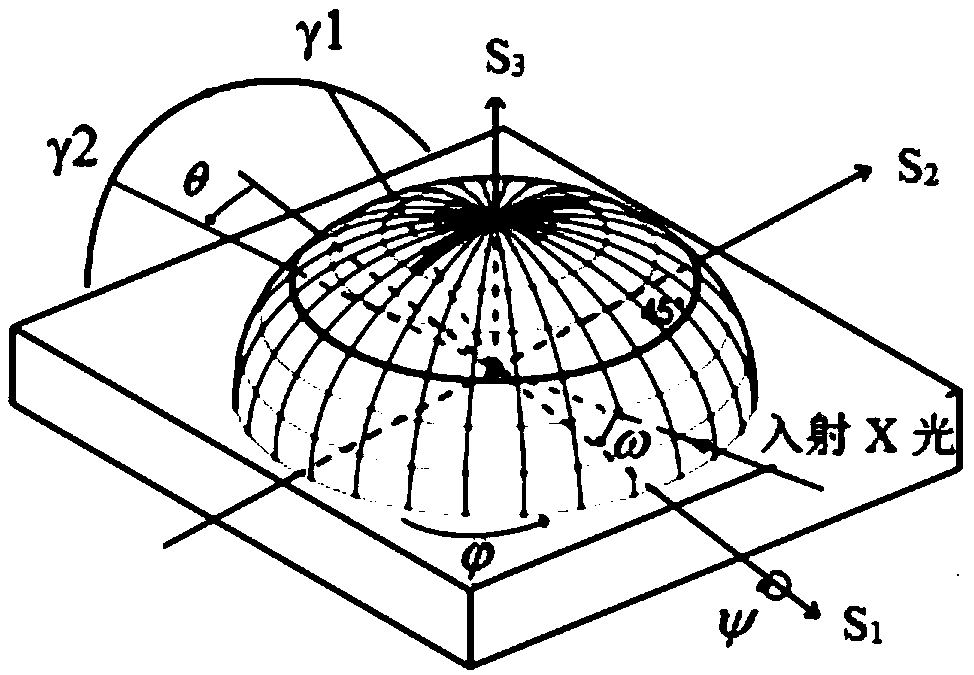

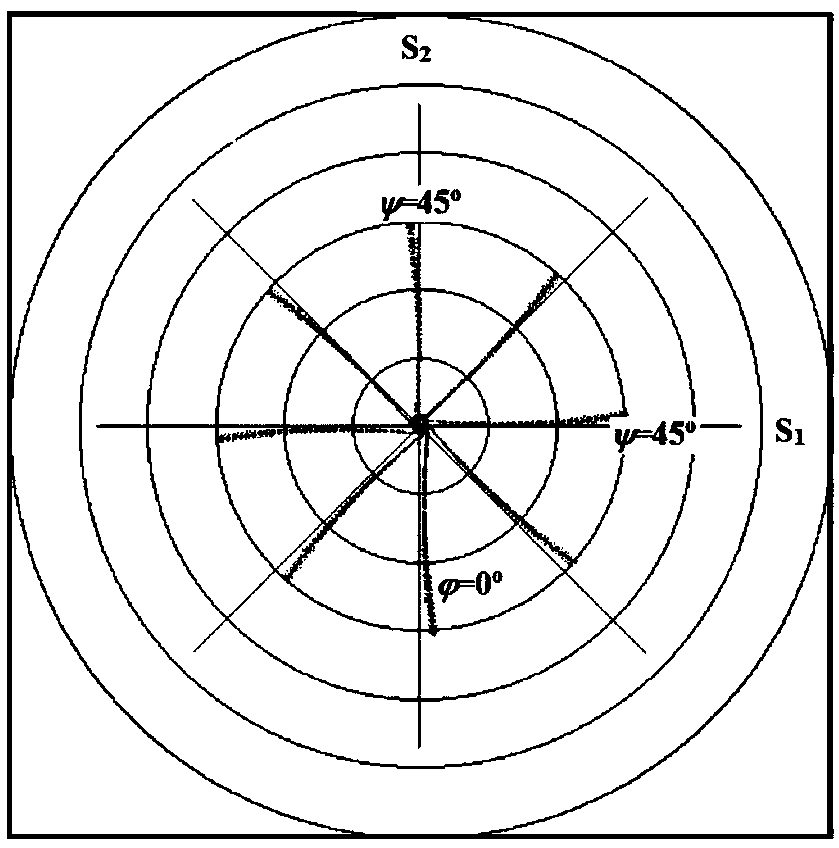

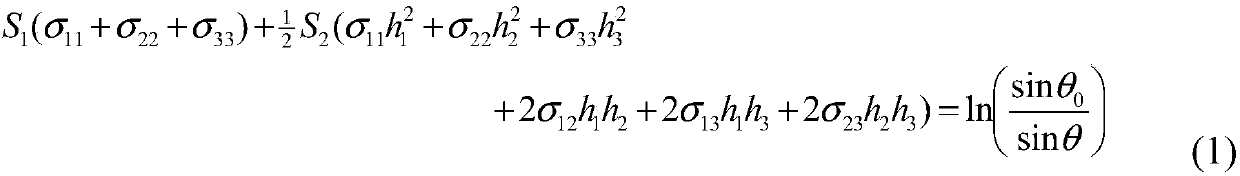

[0065]Two-dimensional X-ray diffraction method was used to quantitatively detect the residual principal stress of the injected diaphragm. At the position to be measured, adjust the detector rotation angle until a sample diffraction arc reaches the middle position of the detector (at this time, the X-ray incident angle and the detector acceptance angle are both 18°), set the upper and lower thresholds of the X-ray diffractometer paramete...

Embodiment 2

[0071] The polymer material product adopted in this embodiment is polypropylene (brand name is NS06). The polypropylene pellets were injection-molded on a Haitian MA900 injection machine into a diaphragm with a size of 60mm×60mm×2mm. The screw is divided into 5 sections, the temperature is 190°C, 180°C, 170°C, 160°C, 150°C respectively, and the mold temperature is 40°C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

[0072] Two-dimensional X-ray diffraction method is used to quantitatively detect the residual principal stress of the film. During the detection process, firstly, the injected membrane is placed on the sample stage of the X-ray diffractometer, and the X-ray incident position is adjusted to a certain point on the surface of the injected membrane to be tested. Position, adjust the detector rotation angle until a sample diffraction arc rea...

Embodiment 3

[0077] The polymer material product adopted in this embodiment is polypropylene (brand name is MM20S). The polypropylene pellets were injection-molded on a Haitian MA900 injection machine into a diaphragm with a size of 60mm×60mm×2mm. The screw is divided into 5 sections, the temperature is 190°C, 180°C, 170°C, 160°C, 150°C respectively, and the mold temperature is 40°C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

[0078] Two-dimensional X-ray diffraction method is used to quantitatively detect the residual principal stress of the film. During the detection process, firstly, the injected membrane is placed on the sample stage of the X-ray diffractometer, and the X-ray incident position is adjusted to a certain point on the surface of the injected membrane to be tested. Position, adjust the detector rotation angle until a sample diffraction arc re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com