A method for rapid detection of residual principal stress of polymer material products

A technology of polymer materials and principal stress, applied in the analysis of materials, material analysis using wave/particle radiation, material analysis using radiation diffraction, etc., can solve problems such as sample center offset and calculation result errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The polymer material article employed in this embodiment is polyethylene (a grade TR480M). The polyethylene pellets were injected on the sea day MA900 injection into a diaphragm and a size of 60 mm × 60 mm × 2 mm. The screw is 5 segments, and the temperature is 180 ° C, 180 ° C, 170 ° C, 160 ° C, 150 ° C, and the mold temperature is 40 ° C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

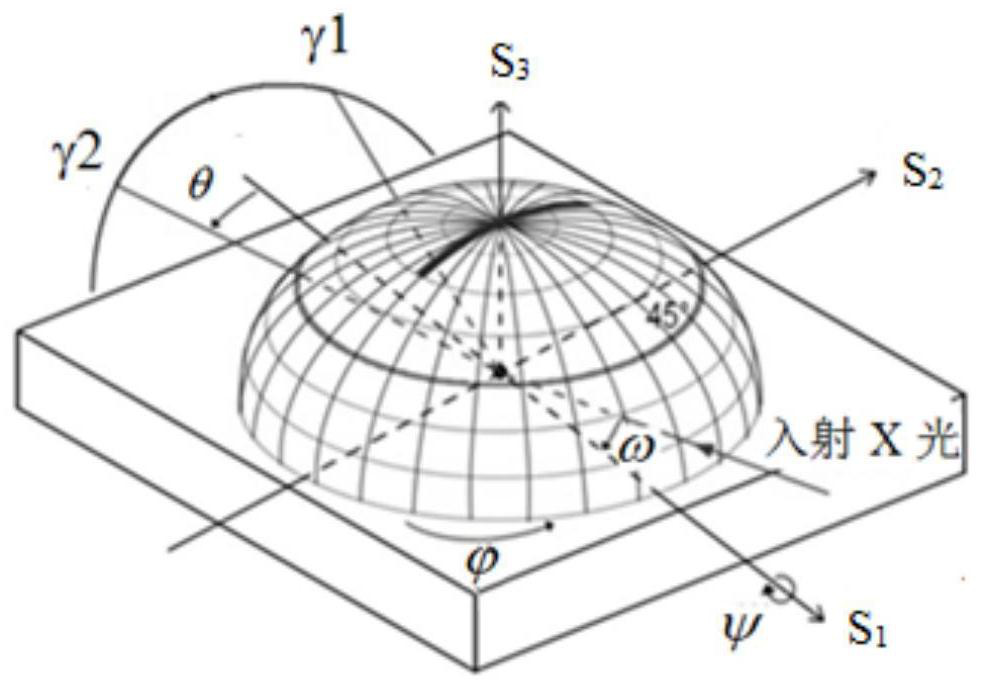

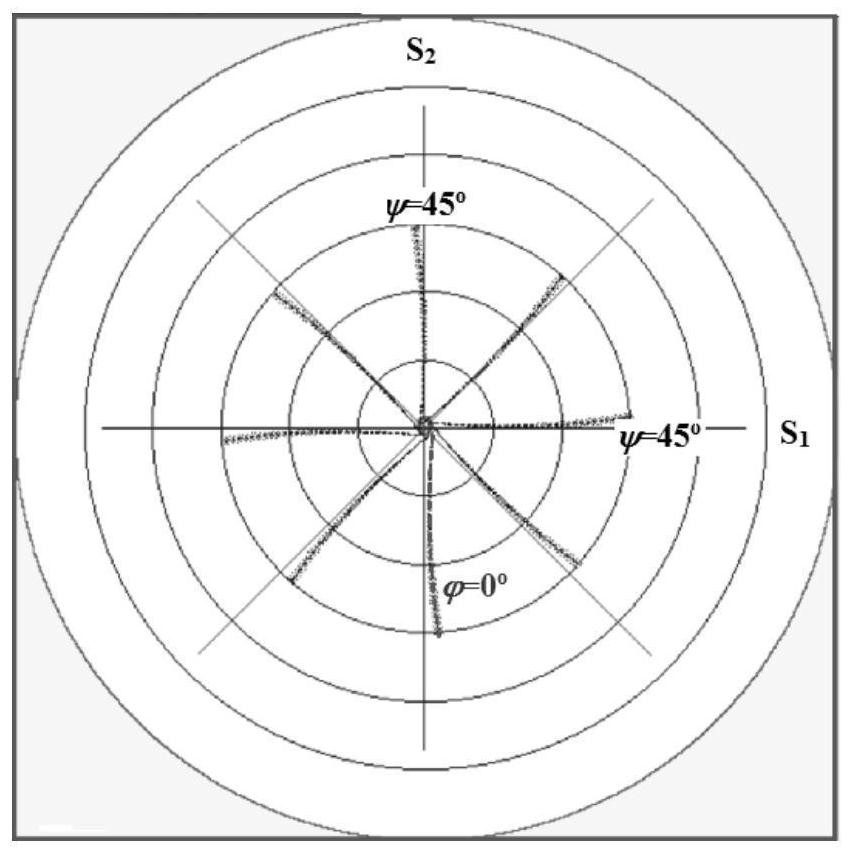

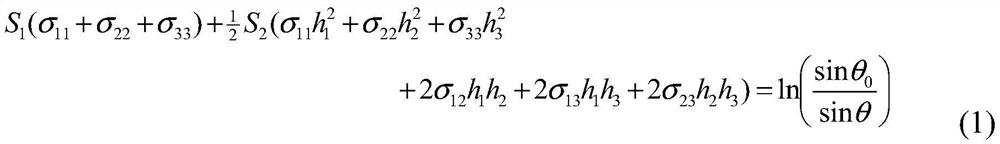

[0065]The residual main stress of the injection diaphragm was quantitatively detected by a two-dimensional X-ray diffraction method. During the detection process, the injection film sheet was first placed in a sample stage of the X-ray diffraction, and the X-ray incident position is adjusted to the surface of the injection film. To be tested, adjust the detector angle to a sample diffraction arc to the intermediate position of the detector (at this time, the X-ray ...

Embodiment 2

[0071] The polymer material articles employed in this example are polypropylene (grades NS06). The polypropylene pellets were injected into a diaphragm on the sea day MA900 injection, and the size was 60 mm × 60 mm × 2 mm. The screw is 5 segments, and the temperature is 190 ° C, 180 ° C, 170 ° C, 160 ° C, 150 ° C, and the mold temperature is 40 ° C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

[0072] The residual main stress of the film was quantitatively detected by a two-dimensional X-ray diffraction method. During the detection process, the injection film sheet was first placed in a sample stage of the X-ray diffraction instrument, and the X-ray incident position to the surface of the injection film surface. Location, adjustment detector angle to a sample diffraction arc to reach the intermediate position of the detector (at this time, the X-ray inc...

Embodiment 3

[0077] The polymer material articles employed in this example are polypropylene (grades MM20S). The polypropylene pellets were injected into a diaphragm on the sea day MA900 injection, and the size was 60 mm × 60 mm × 2 mm. The screw is 5 segments, and the temperature is 190 ° C, 180 ° C, 170 ° C, 160 ° C, 150 ° C, and the mold temperature is 40 ° C. The injection time is 3s, the holding time is 60s, and the cooling time is 10s. The injection pressure is 5 MPa, the screw speed is 45 rpm, and the back pressure is 0.2 MPa.

[0078] The residual main stress of the film was quantitatively detected by a two-dimensional X-ray diffraction method. During the detection process, the injection film sheet was first placed in a sample stage of the X-ray diffraction instrument, and the X-ray incident position to the surface of the injection film surface. Location, adjustment detector angle to a sample diffraction arc to reach the intermediate position of the detector (at this time, the X-ray in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com