A method and system for detecting the broken side of the bearing saddle of a railway freight car

A technology for fault detection and railway freight cars, which is applied in railway vehicle testing, neural learning methods, image data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

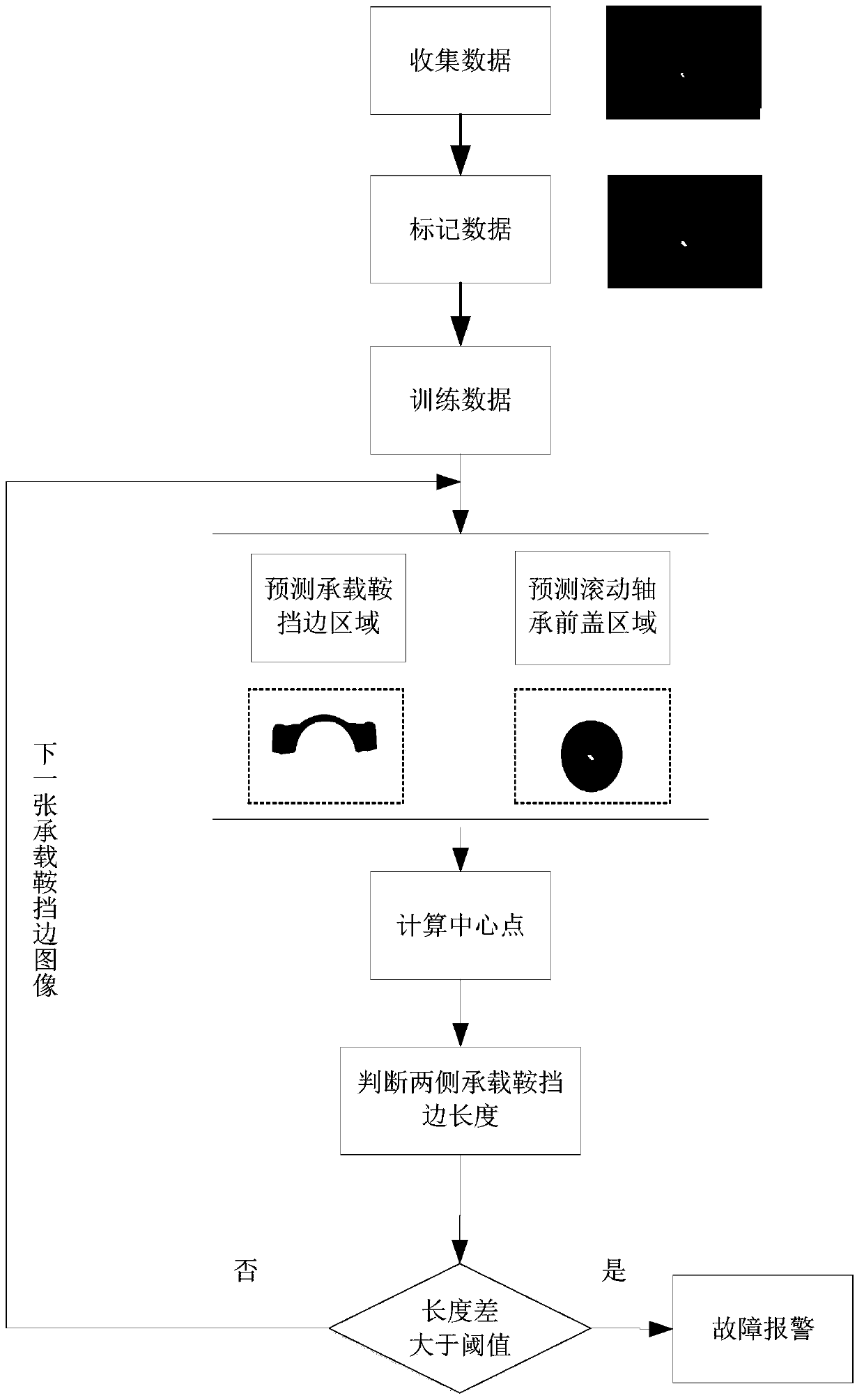

[0068] Specific implementation mode one: refer to figure 1 To describe this embodiment in detail,

[0069] This embodiment is a method for detecting a broken side of a saddle of a railway freight car, which includes the following steps:

[0070] 1. Collect data and label it

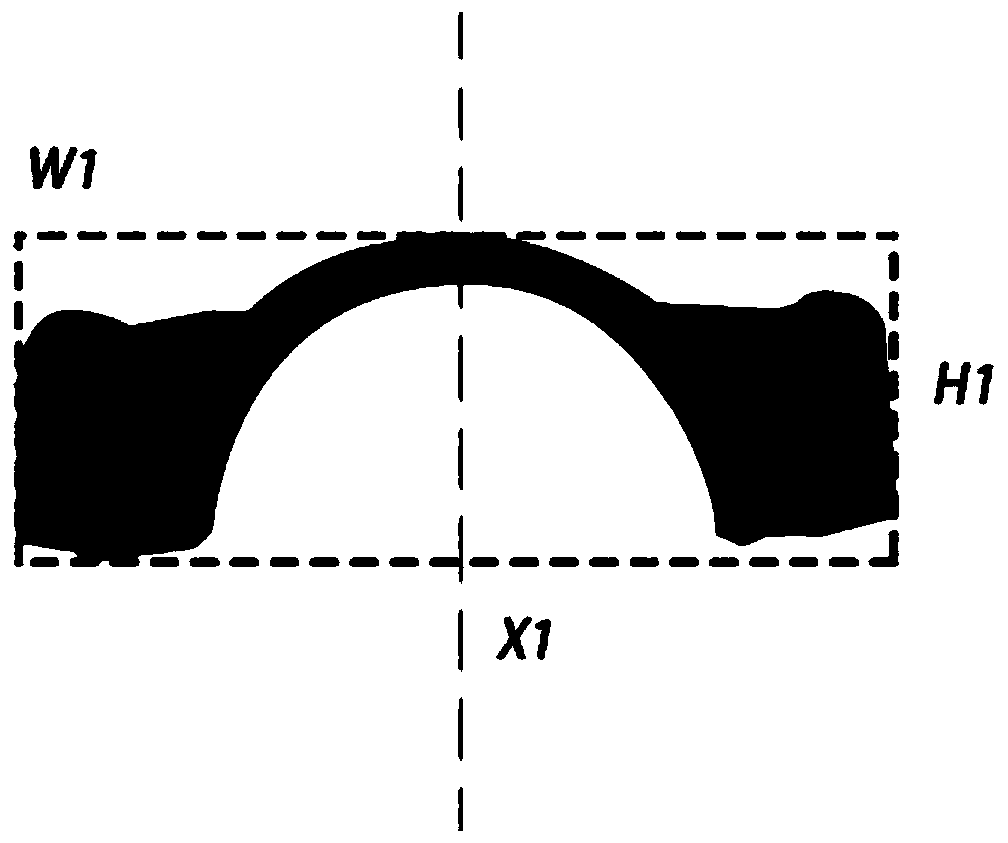

[0071] Take high-definition truck images through the railway pillow equipment. According to the wheelbase information of the train and the prior knowledge of the position of the saddle rib, the sub-image including the saddle rib and the front cover of the rolling bearing is intercepted from the whole truck image. Put the sub-images into the dataset, the size of each sub-image needs to be consistent, and the size of the image must be an integer multiple of 32.

[0072] Because the image of the truck is easily affected by natural conditions such as rain, snow, wind and sand, mud and oil, and the shape of the saddle ribs of different bogie types will also be different. Therefore, in the process of collec...

specific Embodiment approach 2

[0102] This implementation mode is a fault detection system for the breakage of the bearing saddle rib of a railway freight car, and the system includes:

[0103] The image collection unit is used to collect the image of the whole truck, and intercept the sub-image including the bearing saddle rib and the front cover of the rolling bearing;

[0104] A segmentation processing unit, the segmentation processing unit uses a deep learning network model for predicting the image of the bearing saddle rib to be detected, and obtains the segmentation result of the bearing saddle rib and the front cover of the rolling bearing;

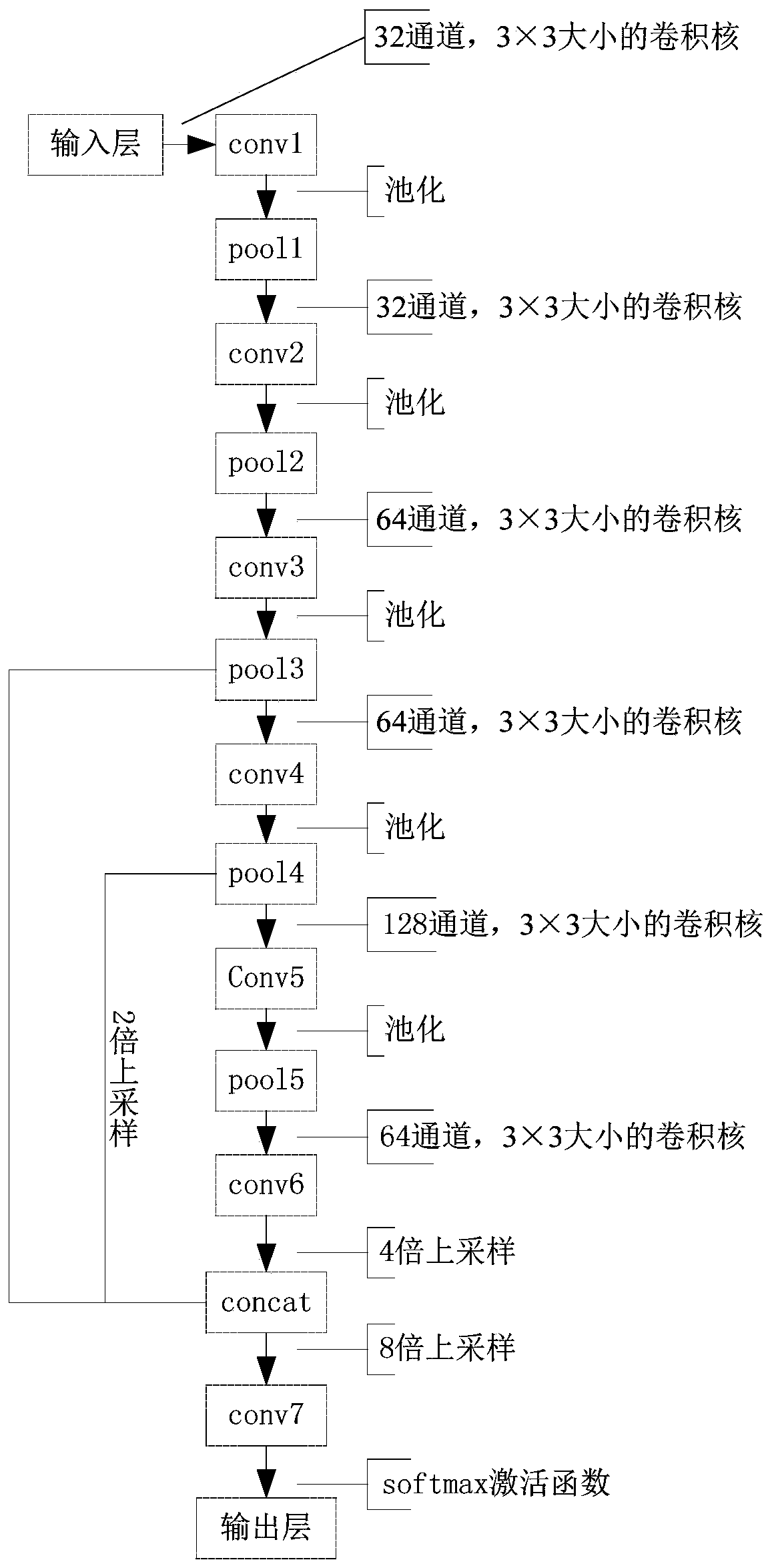

[0105] The described deep learning network model is as follows:

[0106] Input the image into the model, the size of the image is an integer multiple of 32, and use it as the input layer;

[0107] Use a 32-channel, 3×3-sized convolution kernel to convolve the input layer to obtain the conv1 layer, and use a 32-channel, 3×3-sized convolution kernel to convolve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com