Novel winding washing machine motor stator iron core

A motor stator, washing machine technology, applied in electromechanical devices, electrical components, magnetic circuit shape/style/structure, etc., can solve problems such as unstable tooth stacking coefficient, tooth warping deformation, and large gap between laminations, etc. Achieve the effect of smooth and stable winding process, prevent elastic deformation, and small lamination gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

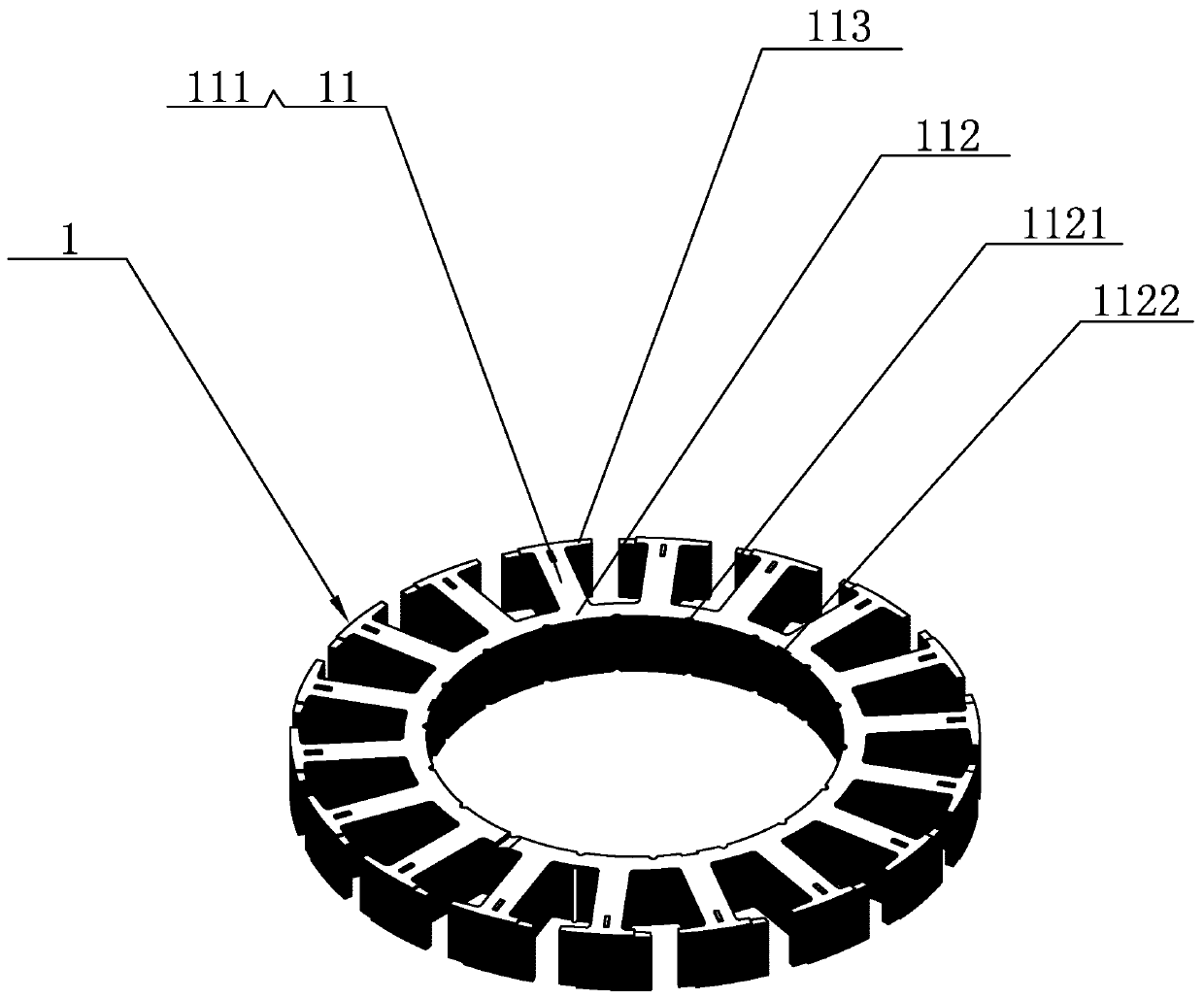

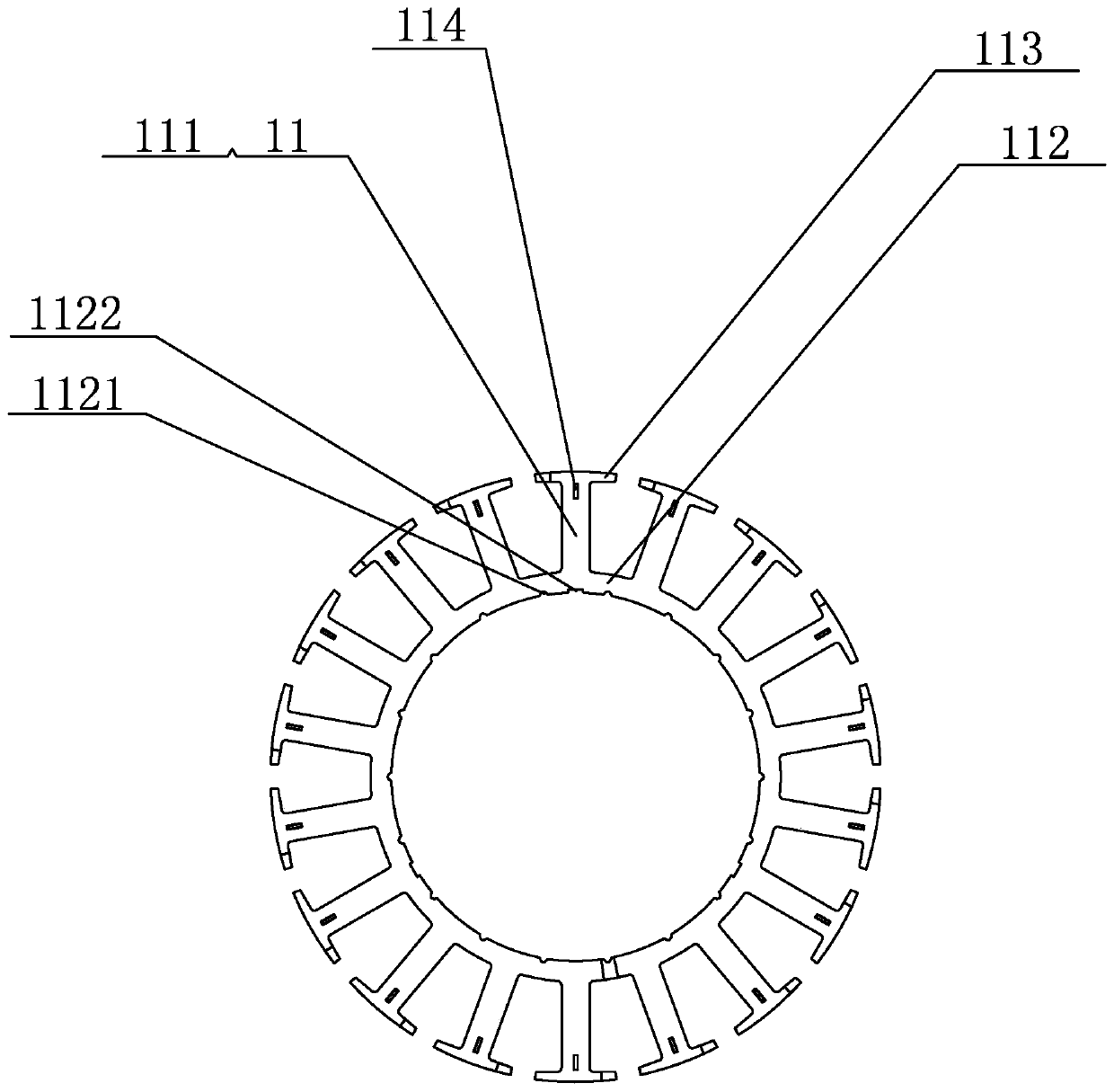

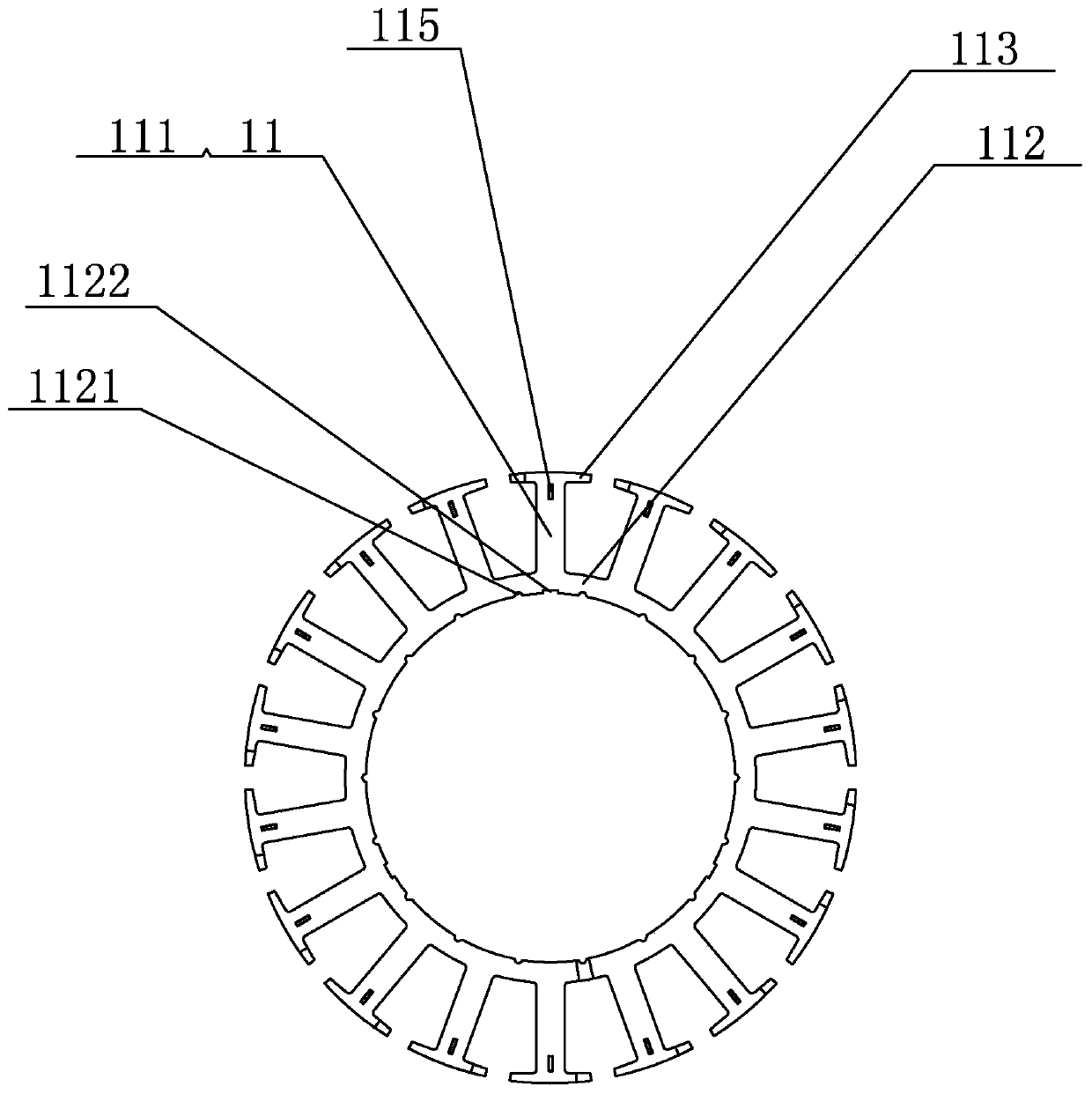

[0027] see figure 1 , figure 2 and image 3 , a novel coiled washing machine motor stator iron core disclosed by the present invention, comprising an iron core body 1, the iron core body 1 is arranged in a ring shape, and the iron core body 1 includes a plurality of silicon steel strips 11, each The silicon steel strip 11 includes a tooth portion 111 and a yoke portion 112, the outer end of the tooth portion 111 is integrally provided with a whisker portion 113, and the inner end of the yoke portion 112 is provided with a yoke anti-wrinkle groove 1121 and an injection molding positioning groove 1122, the injection molding positioning groove 1122 is set to align with the tooth root of the tooth portion 111, and the anti-wrinkle groove 1121 of the yoke portion is set to align with the middle position of two adjacent tooth portions 111; the tooth portion 111 is integrally provided with several There are several buckle points, and the end surface of the other end of the tooth p...

Embodiment 2

[0037] see Figure 4 , Figure 5 and Figure 6 , the second embodiment is an improvement on the basis of the first embodiment above: the upper end surface of the tooth part 111 of each silicon steel strip 11 is provided with a second buckle 116 near the yoke 112, and each silicon steel strip A second buckle slot 117 is provided on the lower end surface of the tooth portion of 11 close to the yoke 112 , and the second buckle slot 117 is located directly below the second buckle point 116 .

[0038] Preferably, the second buckle point 116 of each silicon steel strip 11 is buckled and fixed with the second buckle groove 117 aligned on the lower end surface of the adjacent silicon steel strip 11 directly above.

[0039] In this embodiment, two adjacent silicon steel strips 11 are fastened and fixed by the first buckle point 114 and the matching first buckle groove 115, and the second buckle point 116 is buckled and fixed by the second buckle groove 117 matched therewith. Fixing;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com