Heavy oil hydrotreating catalyst and preparation method and application thereof

A heavy oil hydrogenation and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and hydrocarbon oil treatment, can solve problems affecting the industrial application effect of catalysts, and achieve the goal of saving hydrogenation treatment costs and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

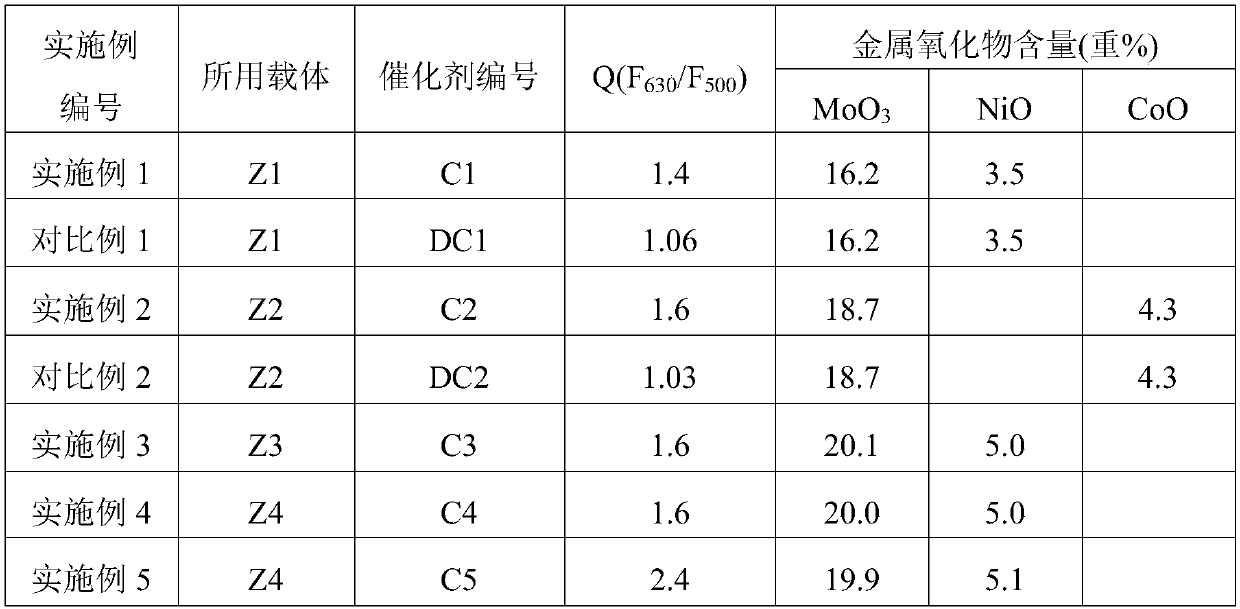

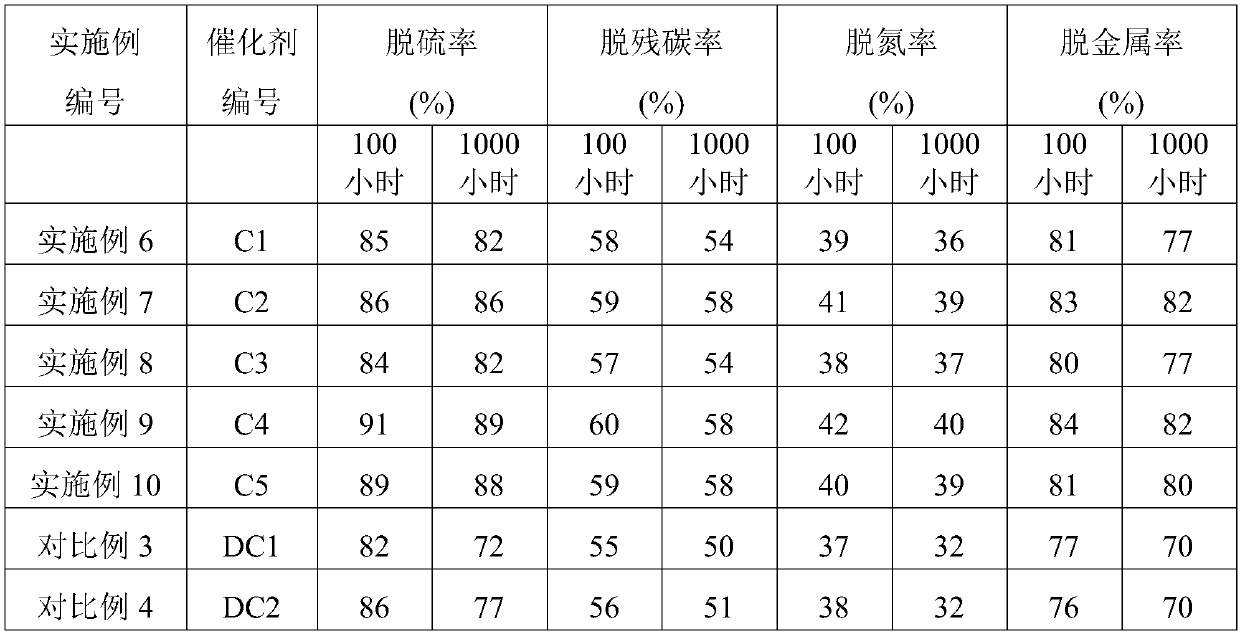

Examples

preparation example Construction

[0058] In the preparation method according to the present invention, the step S1 of treating the carrier includes introducing a sulfur source and a fluorine source into the carrier, followed by drying and calcining. The introduction mentioned here refers to impregnating the support with an aqueous solution containing a sulfur source and a fluorine source.

[0059] Alternatively, the introduction of the sulfur source and the fluorine source can also be carried out simultaneously with the introduction of the metal component.

[0060] As an option, if the selected support itself contains the above-mentioned amounts of sulfur and fluorine, it is only necessary to calcinate the support at high temperature for a certain period of time.

[0061] As a fluorine source, it can be one or more of metal fluoride or ammonium fluoride; as a sulfur source, it can be one or more of sulfuric acid and metal sulfate. The amount of the fluorine source and the sulfur source is such that the finall...

preparation example 1~4

[0084] Preparation of Alumina Support

preparation example 1

[0086] Mix 1 kilogram of pseudo-boehmite dry rubber powder RPB90 produced by Changling Catalyst Factory and 30 grams of fenugreek powder evenly, and at room temperature, this mixture is mixed with 1.1 liters of ammonia fluoride containing 45 grams, and the concentration by weight is 2%. Mix the acetic acid aqueous solution evenly, continue to knead it into a plastic body on a twin-screw extruder, extrude it into a Φ1.1mm trefoil strip, dry the wet strip at 120°C for 3 hours, and then roast it at 800°C for 3 hours to obtain the carrier Z1 . The physical and chemical results of the determination of Z1 are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com