Anti-leaching fertilizer and preparation method thereof

A fertilizer and leaching technology, which is applied to fertilizer mixtures, layered/coated fertilizers, nitrogen fertilizers, etc., can solve the problems of easy leaching and low utilization rate, and achieve a high utilization rate, low cost, and simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

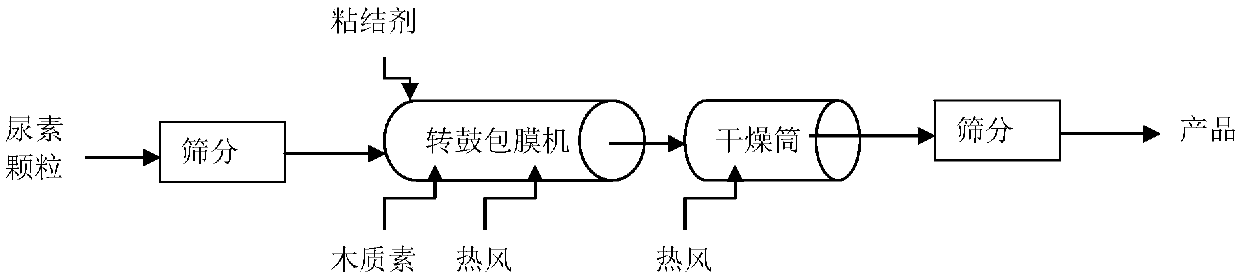

[0023] On the other hand, the embodiment of the present invention also provides a preparation method of anti-leaching fertilizer, comprising the following steps:

[0024] S01: Provide urea granules;

[0025] S02: Preheating the urea granules, spraying the modified lignin solution on the surface of the urea granules, and drying the urea granules to obtain urea granules coated with a bonding layer; wherein, the bonding layer is modified by lignin composition;

[0026] S03: Coating lignin powder on the surface of the bonding layer to form a lignin layer to obtain the leaching-resistant fertilizer.

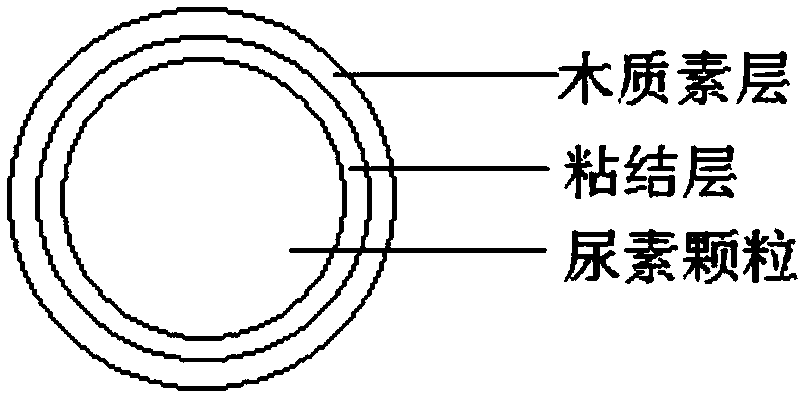

[0027] The preparation method of the leaching-resistant fertilizer provided by the embodiment of the present invention is a fertilizer coating technology process, specifically, first coating the surface of urea particles to form a bonding layer, and then coating the surface of the bonding layer to form a lignin layer, thereby obtaining The anti-leaching fertilizer of the unique stru...

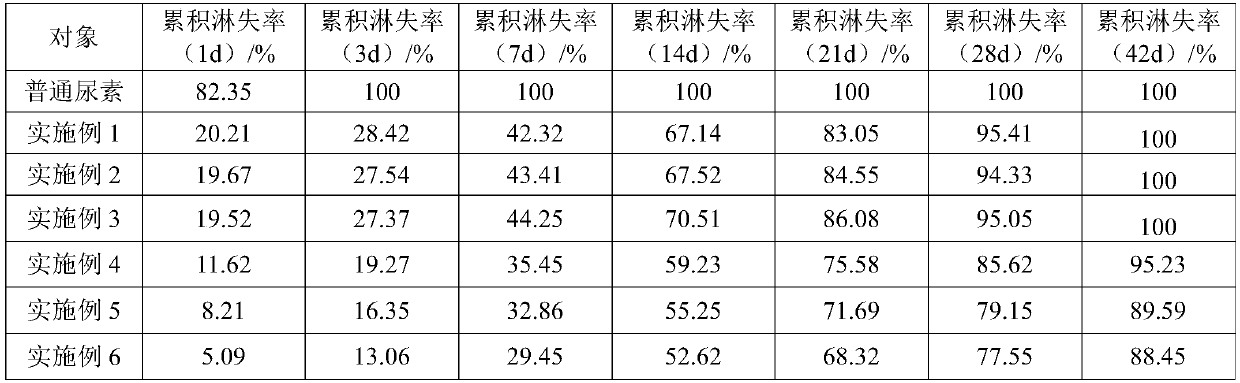

Embodiment 1

[0040] A kind of anti-leaching fertilizer, the composition is as follows:

[0041] Modifier lignin binder: 1 part;

[0043] Urea granules: 98 parts.

[0044] The preparation method comprises: preheating the urea granules, spraying a modified lignin binder on the surface of the urea granules, and drying with hot air to obtain urea granules coated with an adhesive layer; coating the lignin powder A lignin layer is formed on the surface of the bonding layer to obtain a lignin-coated anti-leaching fertilizer.

Embodiment 2

[0046] A kind of anti-leaching fertilizer, the composition is as follows:

[0047] Modifier lignin binder: 2 parts;

[0048] Lignin powder: 1 part;

[0049] Urea granules: 97 parts.

[0050] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com