Halogen-free flame-retardant PA antistatic material and product thereof

An antistatic and flame retardant technology, which is applied in the field of halogen-free flame retardant PA antistatic materials, can solve the problems of high flame retardant grade, decreased mechanical properties, and difficult to achieve materials, so as to expand the application range, antistatic and High flame retardancy improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

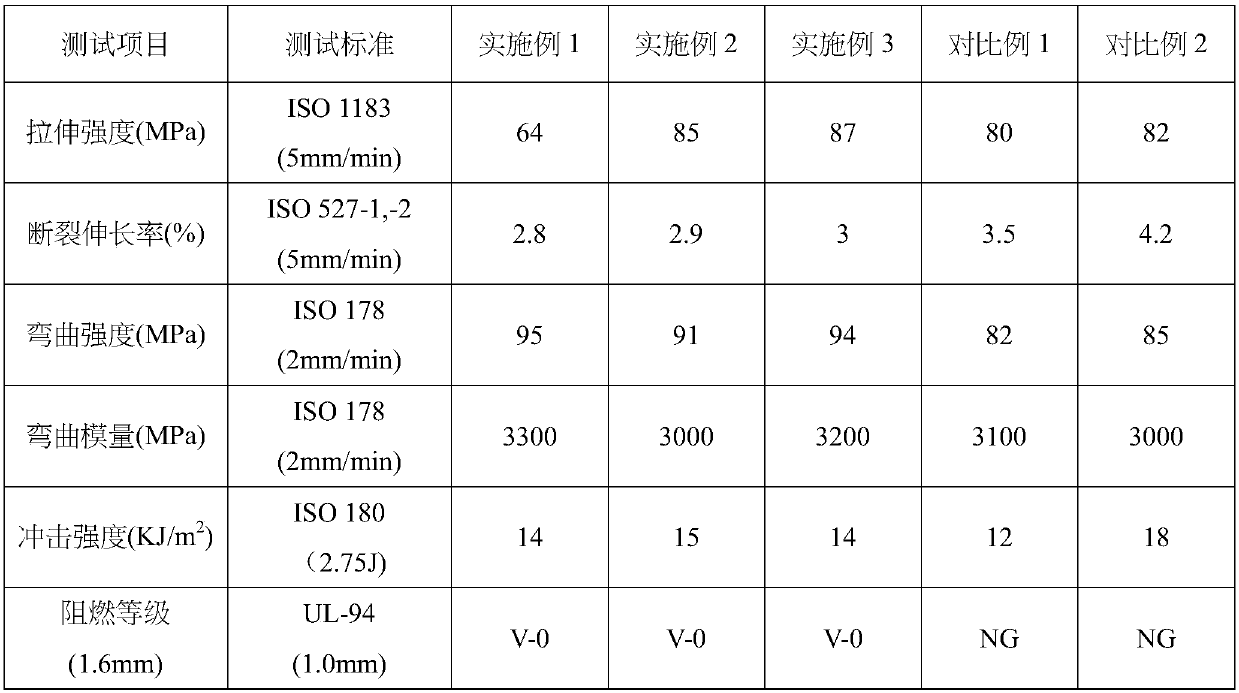

Examples

Embodiment 1

[0027] A halogen-free flame-retardant PA antistatic material, relative to 100 parts by mass of finished material, including 24 parts by mass of PA6, 50 parts by mass of PA66, 20 parts by mass of vinyl aluminum hypophosphite, and 1 part by mass of melamine polyphosphoric acid salt (MCA), 2 parts by mass of propylene-grafted maleic anhydride (PP-g-MAH), 2.5 parts by mass of carbon nanotubes, and 0.5 parts by mass of an anti-dripping agent.

[0028] Weigh the corresponding components in proportion; first add the conductive medium, toughening agent, anti-dripping agent and flame retardant of each component to the PA material in proportion, and use a high-speed mixer to fully and evenly stir; then mix the The materials are melt mixed and extruded to granulate.

Embodiment 2

[0030] A halogen-free flame-retardant PA antistatic material, relative to 100 parts by mass of finished material, including 30 parts by mass of PA6, 50 parts by mass of PA66, 12 parts by mass of vinyl aluminum hypophosphite, and 3 parts by mass of melamine polyphosphoric acid salt (MCA), 2 parts by mass of propylene-grafted maleic anhydride (PP-g-MAH), 2.5 parts by mass of carbon nanotubes, and 0.5 parts by mass of an anti-dripping agent.

[0031] Weigh the corresponding components in proportion; first add the conductive medium, toughening agent, anti-dripping agent and flame retardant of each component to the PA material in proportion, and use a high-speed mixer to fully and evenly stir; then mix the The materials are melt mixed and extruded to granulate.

Embodiment 3

[0033] A halogen-free flame-retardant PA antistatic material, relative to 100 parts by mass of finished material, including 25 parts by mass of PA6, 50 parts by mass of PA66, 15 parts by mass of vinyl aluminum hypophosphite, and 5 parts by mass of melamine polyphosphoric acid salt (MCA), 2 parts by mass of propylene-grafted maleic anhydride (PP-g-MAH), 2.5 parts by mass of carbon nanotubes, and 0.5 parts by mass of an anti-dripping agent.

[0034] Weigh the corresponding components in proportion; first add the conductive medium, toughening agent, anti-dripping agent and flame retardant of each component to the PA material in proportion, and use a high-speed mixer to fully and evenly stir; then mix the The materials are melt mixed and extruded to granulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com