A kind of adhesive remover and preparation method thereof

A technology of remover and viscose, applied in the direction of chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of unfriendly environment, unacceptable, too strong solvency, etc., and achieve the goal of solving odor stimulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

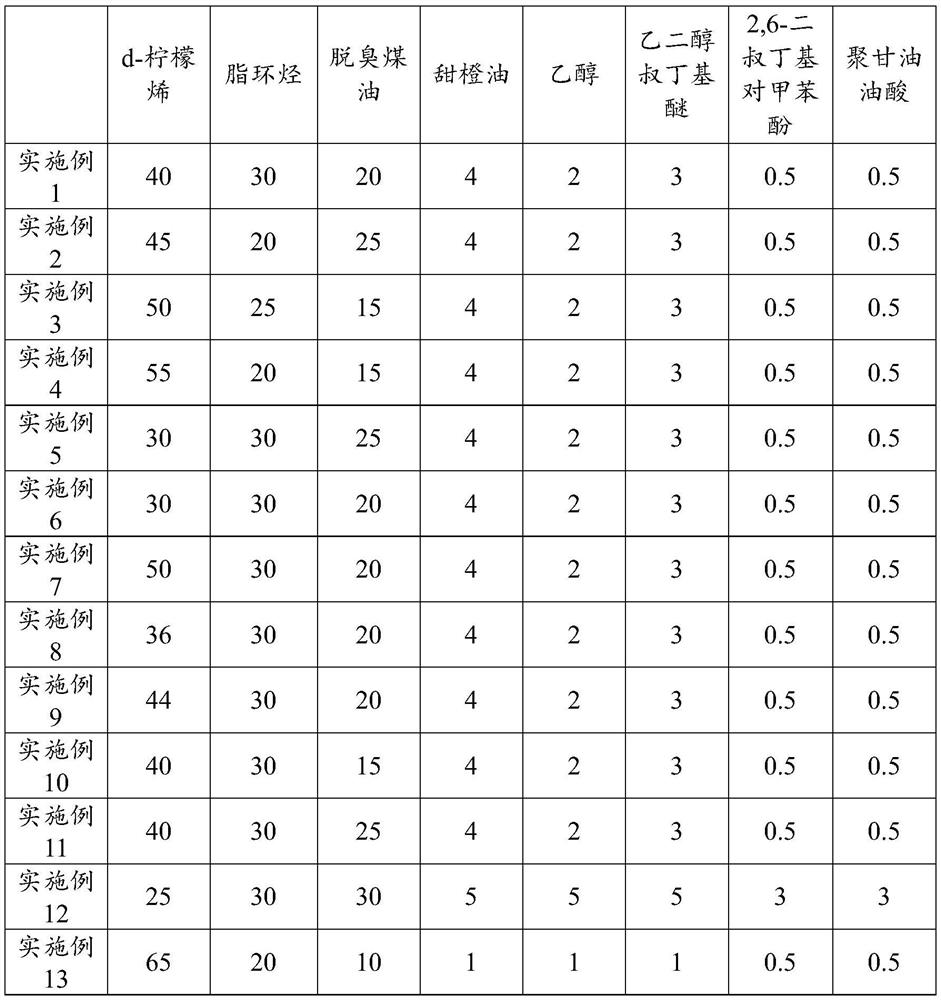

[0042] The present application sets examples 1 to 13, wherein the ingredients and parts by weight in examples 1 to 13 are shown in Table 1, wherein, in each example, the mass percentage of the propellant dimethyl ether in the viscose remover Both are 40%.

[0043] Table 1

[0044]

[0045] Preparation process:

[0046] a. Add each material in the sealed reactor according to the ratio and mix and stir for 10-20 minutes to obtain the material liquid;

[0047] b. Fill the material liquid prepared in step a into an aerosol tin can, then put the valve into the aerosol tin can, then seal it, package the valve and the tin can as a whole, and finally fill the propellant Put it into the aerosol tin can, mix evenly, and get the viscose remover;

[0048] c. The amount of propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com