Treatment method of nickel wet method refining tailings based on high temperature reduction

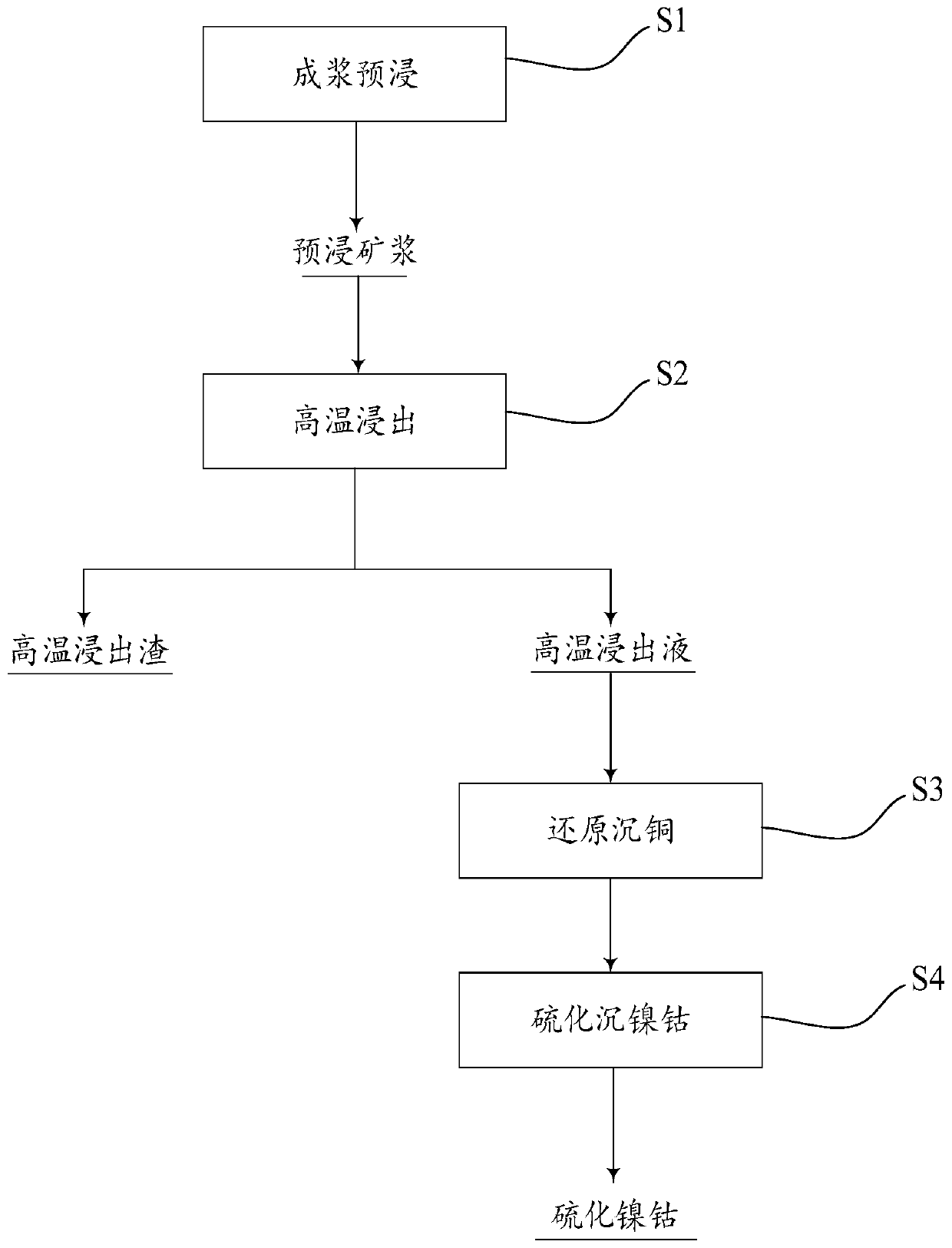

A processing method and high temperature technology, applied in the metallurgical field, can solve the problems of unrecycled nickel and cobalt, nickel slag cannot be directly discharged, unqualified leaching toxicity, etc., and achieve the effect of high economy and resource recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Table 1

[0023] Ni co mn sc Fe Al Cu Cr raw material 0.6201% 0.2827% 0.1829% 0.0797% 14.9174% 1.2646% 0.8371% 0.2087%

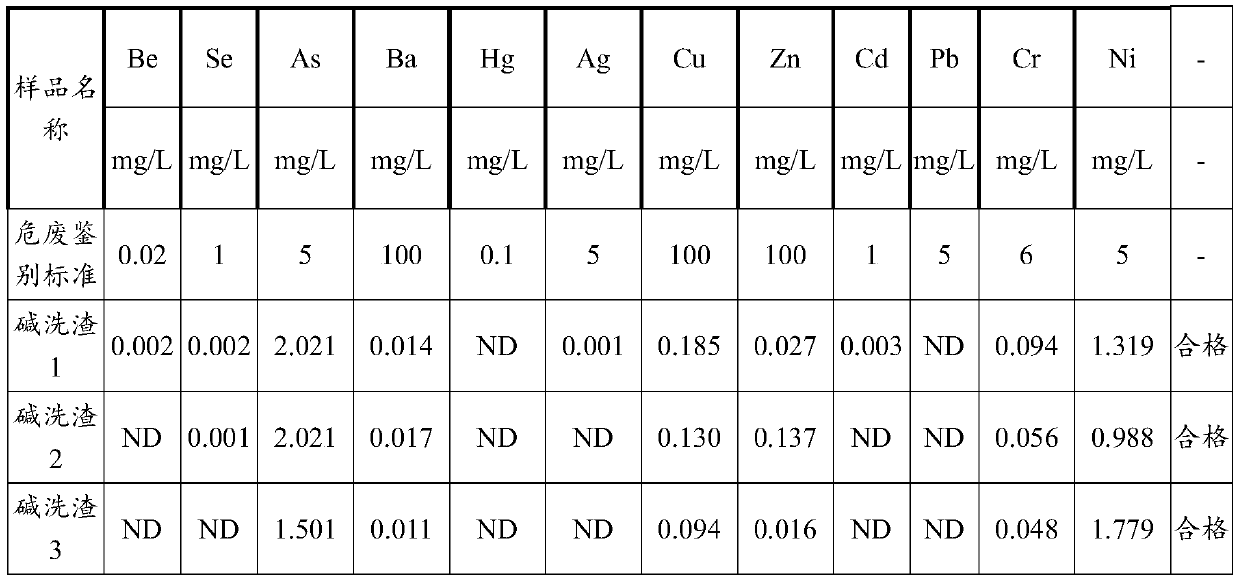

[0024] Take 200g of nickel hydrometallurgy tailings raw material, the mass percentage of each component is shown in Table 1, add water to slurry, add 100g of concentrated sulfuric acid, and pre-soak at 80°C for 1 hour to obtain a pre-soaked slurry. Import the prepreg slurry into a pressure kettle, pressurize and leaching at 150°C for 2 hours, the total pressure in the kettle is 0.5MPa, and obtain leachate and leach slag after solid-liquid separation. Among them, the nickel leaching rate is 97%, the manganese leaching rate is 98%, and the cobalt leaching rate is 95%, (13.2%-46.9%). Wash the leach residue twice with water at a liquid-solid ratio of 3:1, and then wash it once with alkali at a pH of 8.0 to 8.5 to obtain general solid waste and nickel leachate that can meet the discharge standard, wherein nickel in...

Embodiment 2

[0026] Take 200g of nickel hydrometallurgy tailings raw material, the mass percentage of each component is the same as in Example 1, add water to slurry, add 60g of concentrated sulfuric acid, and pre-soak at 80°C for 1 hour to obtain a pre-soaked slurry. The prepreg slurry was introduced into a pressurized autoclave, and leached under pressure at 180°C for 5 hours. The total pressure in the autoclave was 0.97MPa. After solid-liquid separation, leachate and leaching residue were obtained. Among them, the nickel leaching rate is 98%, the manganese leaching rate is 95%, and the cobalt leaching rate is 94.5%. Wash the leach residue twice with water at a liquid-solid ratio of 3:1, and then wash it once with alkali at a pH of 8.0 to 8.5 to obtain general solid waste and nickel leachate that can meet the discharge standard, wherein nickel in the leachate: 1.84g / L, Cobalt: 0.45g / L, manganese: 0.52g / L, total iron: 5.2g / L, ferrous iron: 3.7g / L, copper: 0.83g / L. Into the high-temperatu...

Embodiment 3

[0028] Take 200g of nickel hydrometallurgy tailings raw material, the mass percentage of each component is the same as in Example 1, add water to slurry, add 40g of concentrated sulfuric acid, and pre-soak at 80°C for 1 hour to obtain a pre-soaked slurry. The prepreg slurry was introduced into a pressurized kettle, and leached under pressure at 200°C for 5 hours, the total pressure in the kettle was 0.97MPa, and the leachate and leaching residue were obtained after solid-liquid separation. Among them, the nickel leaching rate is 99%, the manganese leaching rate is 98%, and the cobalt leaching rate is 98%. Wash the leach residue twice with water at a liquid-solid ratio of 3:1, and then wash it once with alkali at a pH of 8.0 to 8.5 to obtain general solid waste and nickel leachate that can meet the discharge standard, wherein nickel in the leachate: 1.86g / L, Cobalt: 0.46g / L, manganese: 0.53g / L, total iron: 3.5g / L, ferrous iron: 3.5g / L, copper: 0.83g / L. Into the high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com