A Low Frequency Vibration Isolation Superstructure

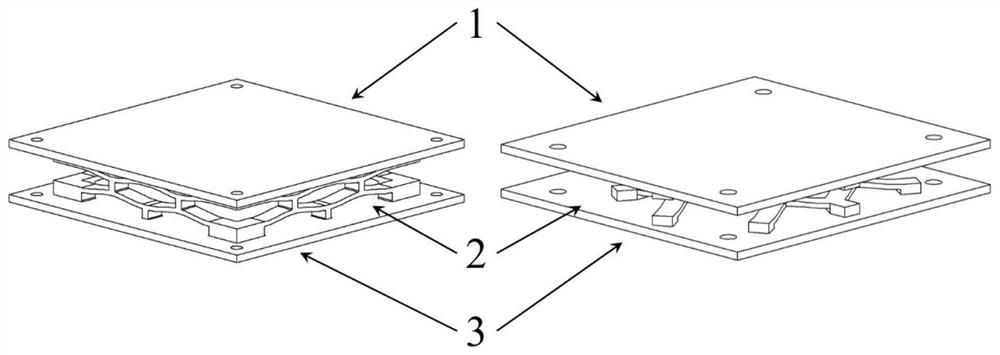

A superstructure and vibration isolation technology, applied in vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problems of narrow operating frequency band, neglect of static load engineering requirements, etc., achieve a wide vibration isolation frequency range, shorten development Period and good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

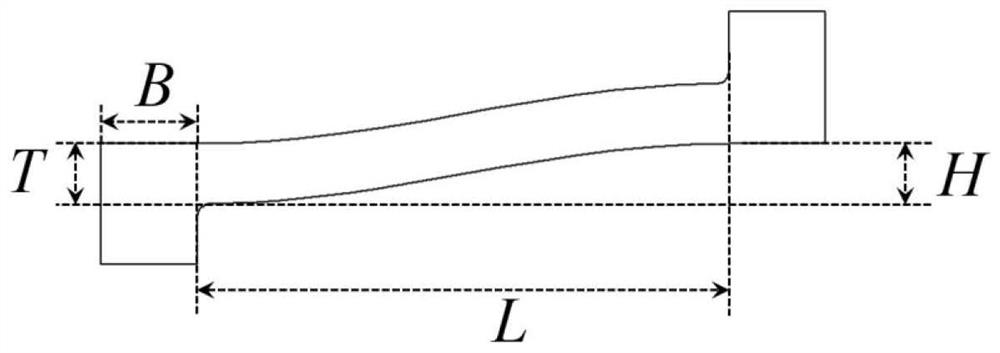

[0049] The rated load of the CMG equipment of a certain type of satellite is 160N. The bottom size of the CMG equipment is a circle with a radius of 111mm. The frequency is concentrated at 50Hz, 100Hz, 160Hz and 200Hz; at the same time, the device will also generate linear vibration in X and Z directions and angular vibration in X, Y and Z directions. The design goal is to make the superstructure able to carry the rated load while well isolating the linear vibration above 30Hz in the Y direction of the equipment, and at the same time have a certain suppression effect on other forms of vibration of the equipment.

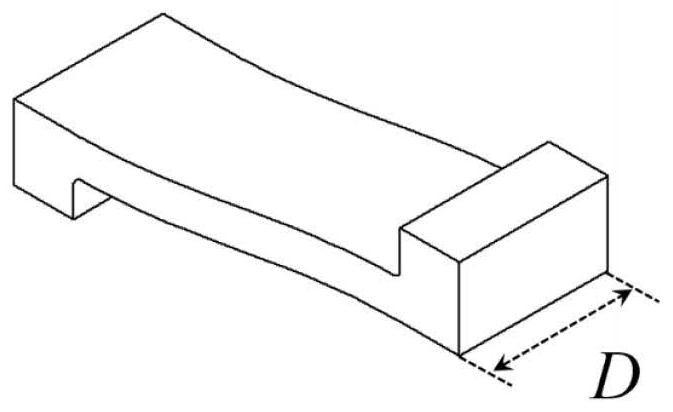

[0050] According to the design and manufacture method of the low-frequency vibration-isolation superstructure, the following design scheme is selected: select the future 8000 type photosensitive resin of the Shenzhen Future Factory as the base material of the low-frequency vibration-isolation superstructure, with an elastic modulus of 1400MPa and a density of 1131kg / m...

Embodiment 2

[0053] The rated load of a certain vibration source equipment is 2800N, and the main vibration form during operation is the linear vibration in the Y direction (perpendicular to the direction of the upper mounting panel). The main frequencies of this form of vibration are concentrated at 15Hz, 23Hz and 60Hz; The equipment also produces linear vibrations in X, Z directions and angular vibrations in X, Y, Z directions. The design goal is to make the superstructure able to carry the rated load while well isolating the linear vibration above 10Hz in the Y direction of the equipment, and at the same time have a certain suppression effect on other forms of vibration of the equipment.

[0054] According to the design and manufacture method of the low-frequency vibration-isolation superstructure, the following design scheme is selected: AlSi10Mg alloy is selected as the base material of the low-frequency vibration-isolation superstructure, with an elastic modulus of 80GPa and a density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com