Method for analyzing and predicting strength of crack-containing ferroelectric material under effect of force-electricity-heat coupling field

A technology of ferroelectric materials and prediction methods, applied in chemical property prediction, computer material science, cheminformatics data warehouse, etc., can solve the lack of systematic research, the inability to simulate the evolution of ferroelectric microstructure, and the inability to accurately reflect the physical essence and other problems, to achieve good adaptability and stability, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

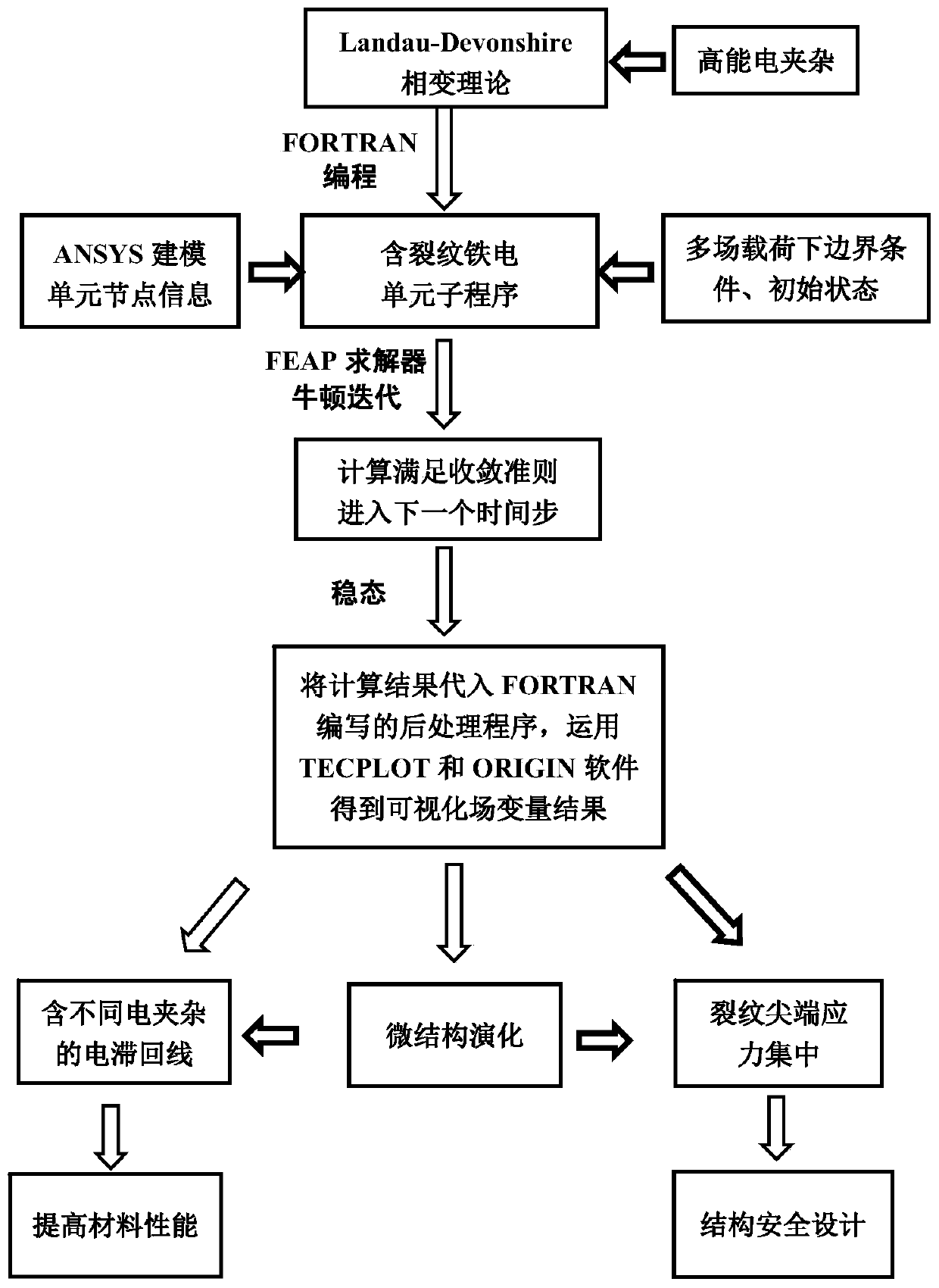

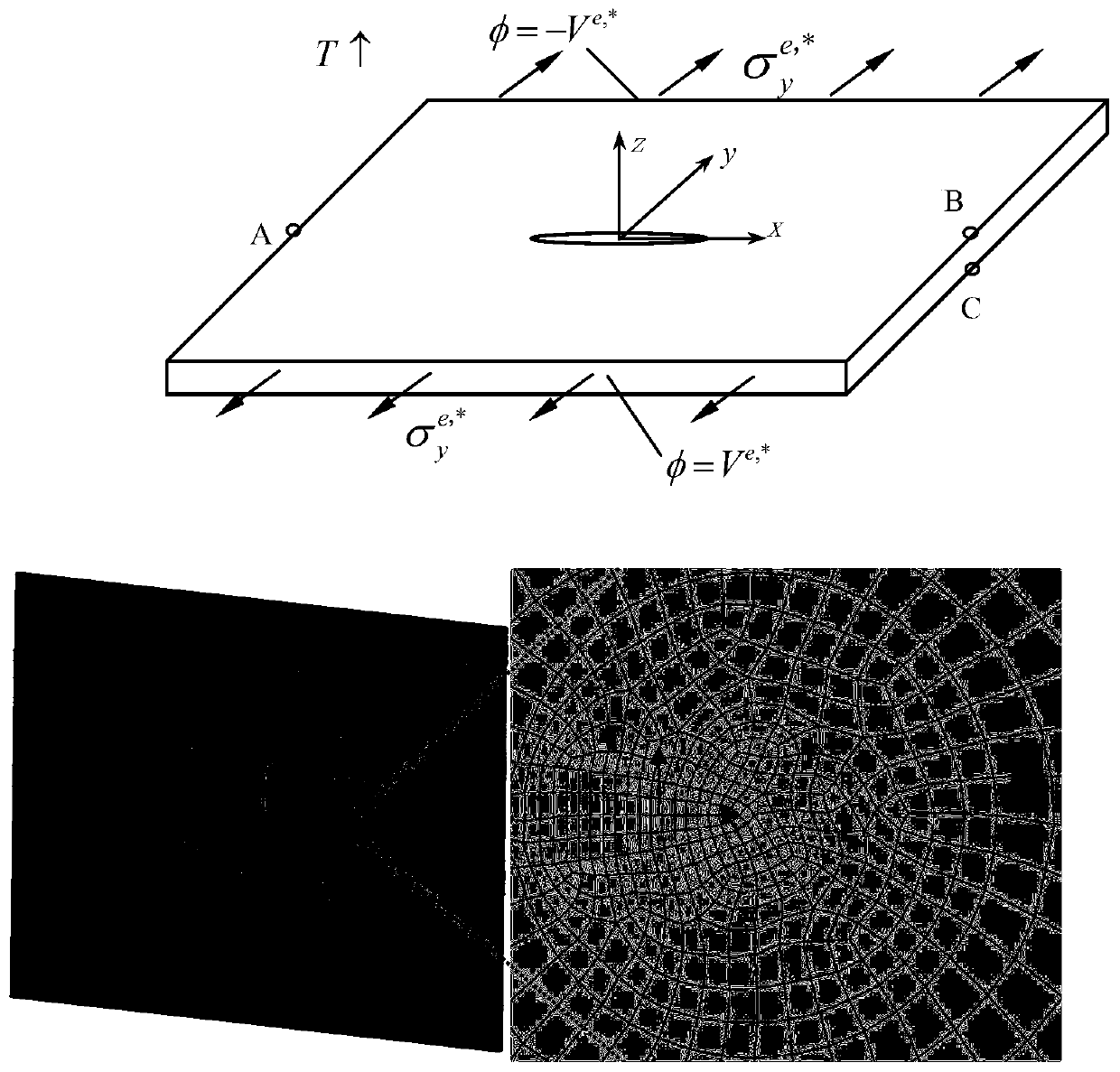

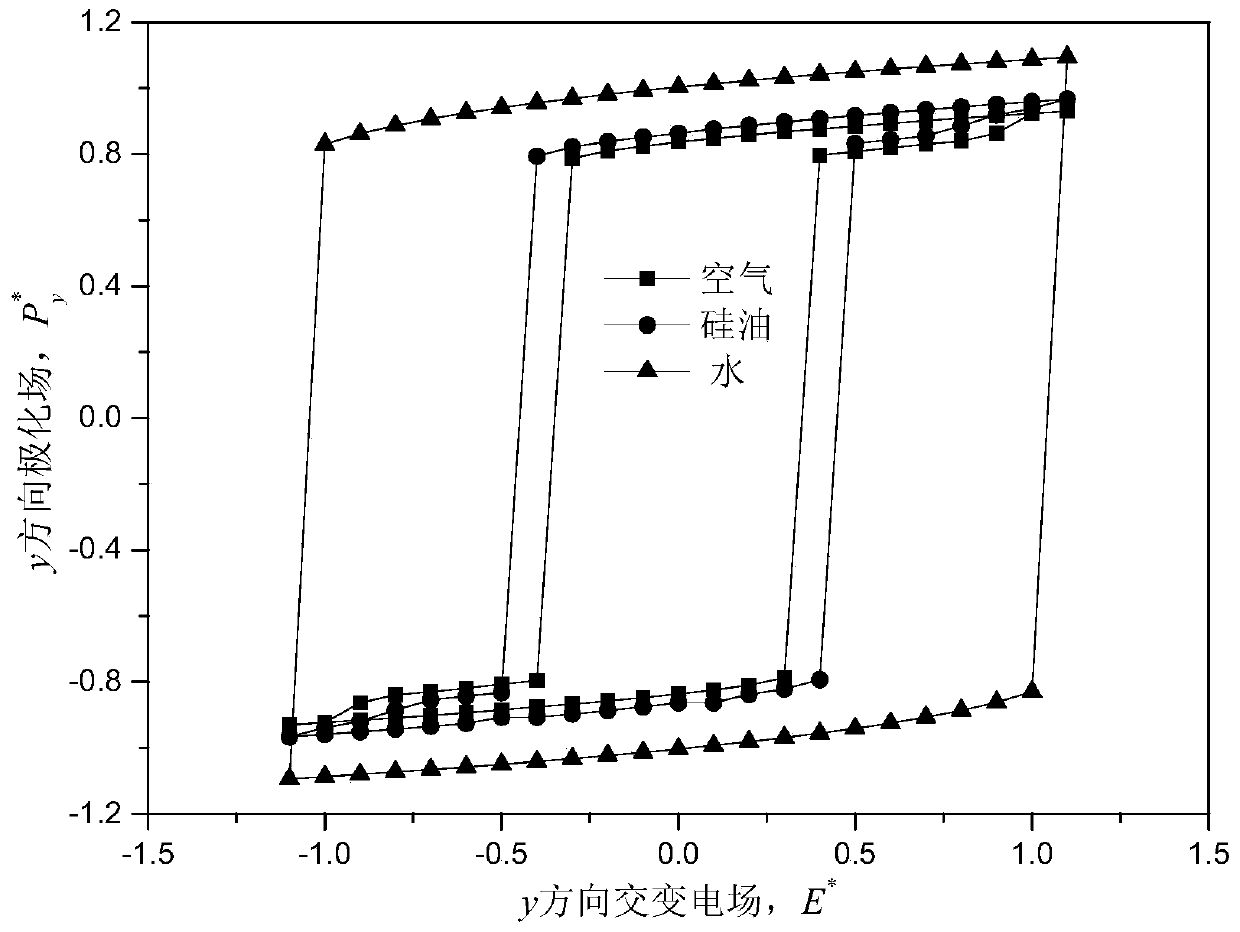

[0025] The elliptical crack in the ferroelectric material is simulated as an electric inclusion model, that is, the inside of the crack is simulated by an electric inclusion with the same dielectric constant as water, silicone oil or air. In order to focus on the influence of external loads on ferroelectric materials, the electric inclusions here only consider the electric energy, ignoring the influence of small elastic energy; at the same time, it is assumed that the electric inclusions have good dielectric properties, and the influence of temperature changes on the dielectric properties of the electric inclusions is ignored. Constant influence. The invention provides a powerful finite element simulation method, by studying the interaction between electric inclusions and microstructures, the electric hysteresis loops of different electric inclusion models ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com