Sliced bread

A technology for slicing bread and salt, which is applied in the processing of dough, baking, and baked goods with modified ingredients, etc., and can solve the problems of inability to meet living needs, single taste, and lack of functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

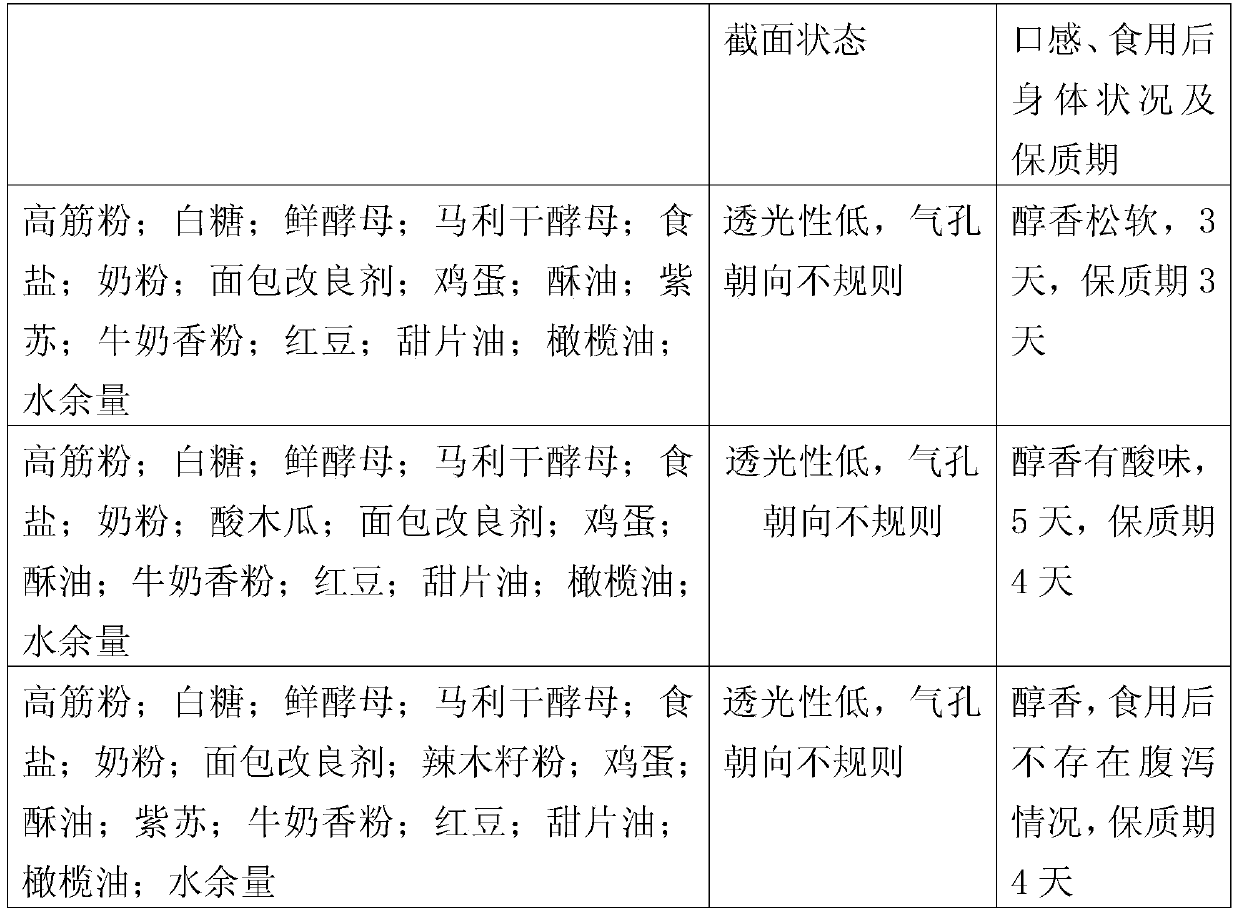

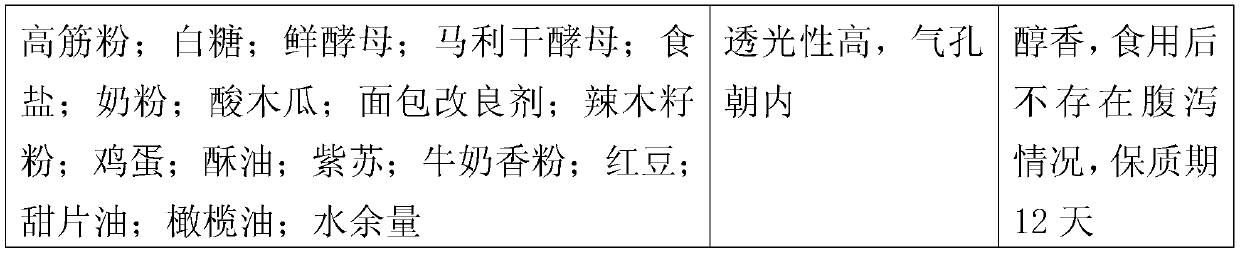

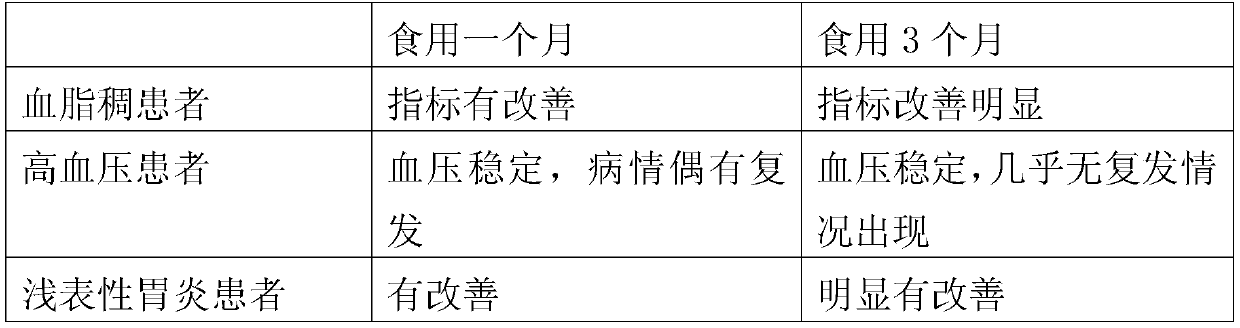

Examples

Embodiment 1

[0050] The sliced bread of the present embodiment comprises the following components by mass percentage: high-gluten flour 70%; white sugar 1.5%; fresh yeast 0.2%; Marley dry yeast 1.1%; salt 0.7%; milk powder 0.8%; sour papaya 0.1%; Bread Improver 0.1%; Moringa Seed Powder 0.01%; Egg 2.5%; Ghee 1%; water balance.

[0051] The sour papaya is washed with edible alkali, dried in the air, dried in a dryer, and then made into a powder state by a milling machine.

[0052] 0.55<the dried water activity of the sour papaya<0.8.

[0053] The table salt adopts low-sodium table salt, and the table salt is used after being ground and sieved.

[0054] The temperature of the cut bread and noodle is 27°C.

[0055] After removing the shell of the Moringa seed, soak it for 2 minutes, remove it and dry it, and make it into a powder state through a milling machine; put the Moringa seed shell into the above-mentioned water by mass percentage and soak it for 1 hour, then remove it, and Reser...

Embodiment 2

[0061] The sliced bread of the present embodiment comprises the following components by mass percentage: high-gluten flour 80%; white sugar 2%; fresh yeast 0.4%; Marley dry yeast 1.6%; salt 1.8%; milk powder 5%; sour papaya 1%; Bread Improver 2%; Moringa Seed Powder 0.5%; Egg 9%; Ghee 8%; water balance.

[0062] The sour papaya is washed with edible alkali, dried in the air, dried in a dryer, and then made into a powder state by a milling machine.

[0063] 0.55<the dried water activity of the sour papaya<0.8.

[0064] The table salt adopts low-sodium table salt, and the table salt is used after being ground and sieved.

[0065] The temperature of the cut bread and noodle is 28°C.

[0066] After removing the shell of the Moringa seed, soak it for 5 minutes, remove it and dry it, and make it into a powder state through a milling machine; put the Moringa seed shell into the above-mentioned water by mass percentage and soak it for 2 hours, and remove it. Reserve the water af...

Embodiment 3

[0072] The sliced bread of the present embodiment comprises the following components by mass percentage: high-gluten flour 72%; white sugar 1.52%; fresh yeast 0.2.4%; Marley dry yeast 1.12%; salt 0.8%; milk powder 0.85%; Sour Papaya 0.2%; Bread Improver 0.15%; Moringa Seed Powder 0.025%; Egg 3%; Ghee 2%; %; water balance.

[0073] The sour papaya is washed with edible alkali, dried in the air, dried in a dryer, and then made into a powder state by a milling machine.

[0074] 0.55<the dried water activity of the sour papaya<0.8.

[0075] The table salt adopts low-sodium table salt, and the table salt is used after being ground and sieved.

[0076] The temperature of the cut bread and noodle is 27°C.

[0077] After removing the shell of the Moringa seed, soak it for 3 minutes, take it out and dry it, and make it into a powder state through a milling machine; put the Moringa seed shell into the above-mentioned water by mass percentage and soak it for 1.2 hours, then pull it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com