Tobacco leaf modulation process method based on time oscillation

A process method and time technology are applied in the field of time oscillation tobacco leaf modulation process to achieve the effects of moderate thickness, strong gloss and improved apparent morphological characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: (A time oscillating tobacco leaf modulation process is applied to the air-flow ascending horizontal intensive curing barn)

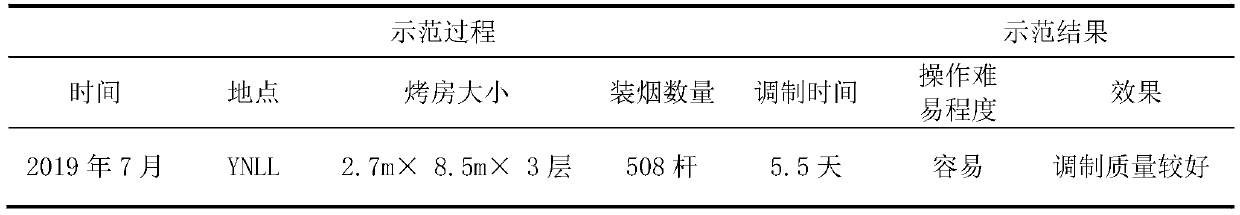

[0028] The verification process and results are shown in Table 1:

[0029] Table 1 The results of a time-oscillating tobacco leaf modulation process applied to an ascending-airflow horizontal intensive curing barn

[0030]

[0031] Evaluation of time-oscillating tobacco leaf brewing process: the brewing process is accelerated, the brewing time is shortened, the brewing quality is better, labor and cost are saved, energy is saved and emissions are reduced.

[0032] Statistics of brewing quality: Compared with the brewing quality of the large-area upward airflow horizontal intensive curing barn, the proportion of high-quality tobacco leaves increased by 4.05%, the proportion of medium-grade tobacco leaves increased by 5.80%, and the cost of brewing was saved by 7.88%. The economic benefits are very significant.

[0033] Tobacco leaf p...

Embodiment 2

[0034] Example 2: (A time oscillating tobacco leaf modulation process method is applied to the airflow descending horizontal intensive barn)

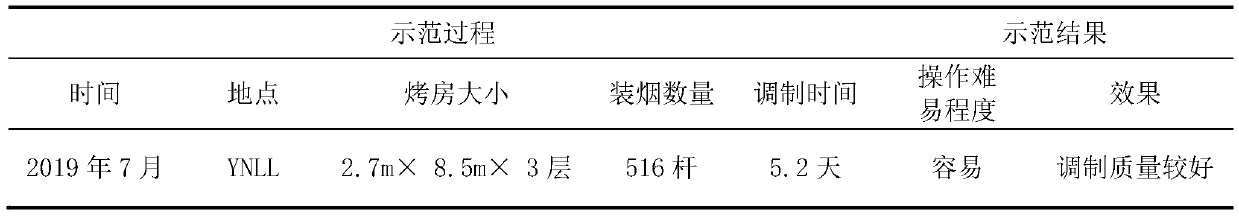

[0035] The verification process and results are shown in Table 1:

[0036] Table 1 The results of a time-oscillating tobacco leaf modulation process applied to a horizontal intensive barn with downward air flow

[0037]

[0038] Evaluation of time-oscillating tobacco leaf brewing process: the brewing process is accelerated, the brewing time is shortened, the brewing quality is better, labor and cost are saved, energy is saved and emissions are reduced.

[0039] Statistics of brewing quality: Compared with the brewing quality of large-area air-flow descending horizontal intensive barn, the proportion of high-quality tobacco leaves increased by 4.50%, the proportion of medium-grade tobacco leaves increased by 7.30%, and the cost of brewing was saved by 9.09%. The economic benefits are very significant.

[0040] Tobacco leaf preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com