Sewage processing equipment settling pond circulating sludge stirring structure

A technology of sewage treatment equipment and sedimentation tank, which is applied in the direction of flocculation/sedimentation water/sewage treatment, sedimentation separation, feeding/discharging device of settling tank, etc. It can solve the problems of sludge floating and other problems, achieve complete mixing and easy installation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

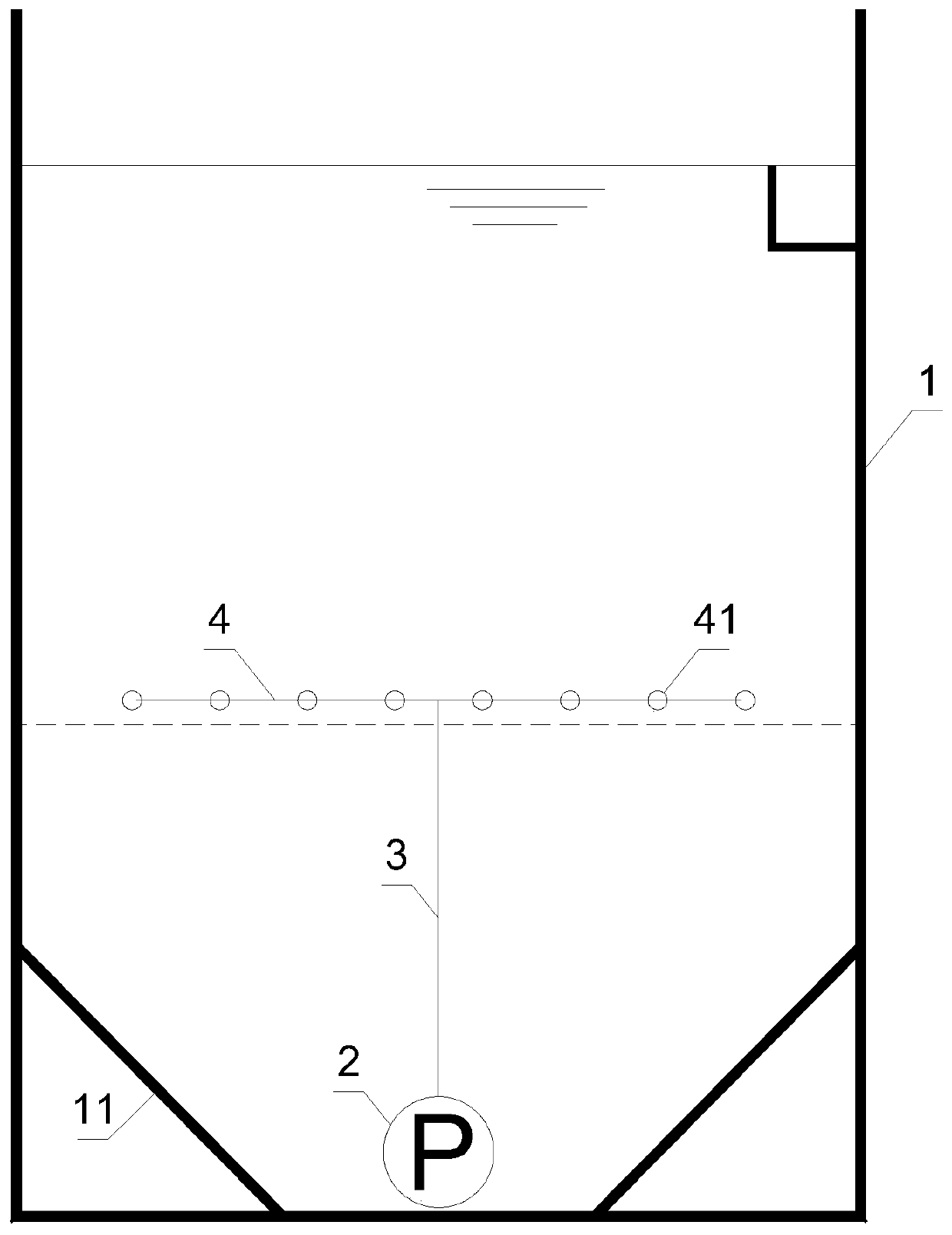

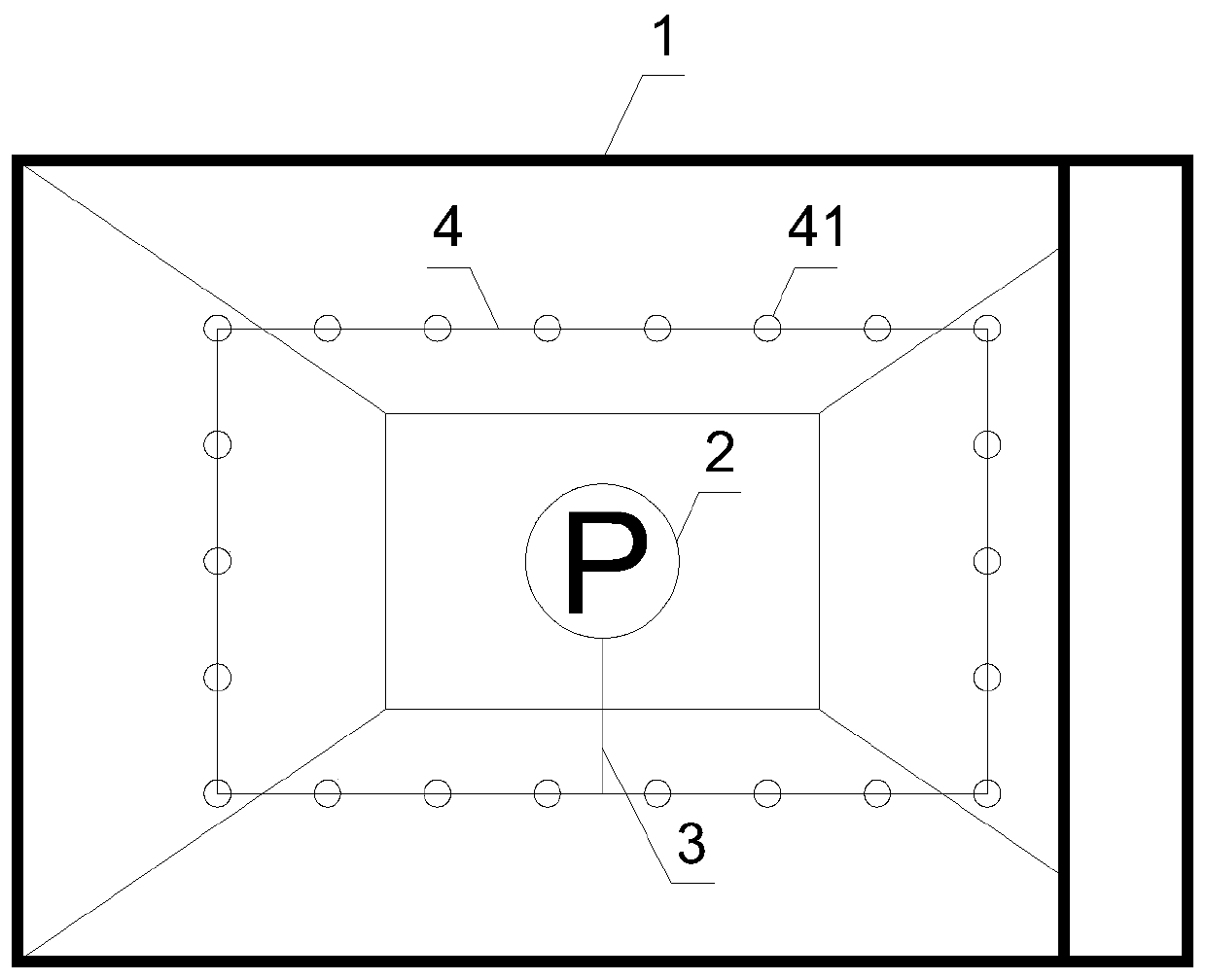

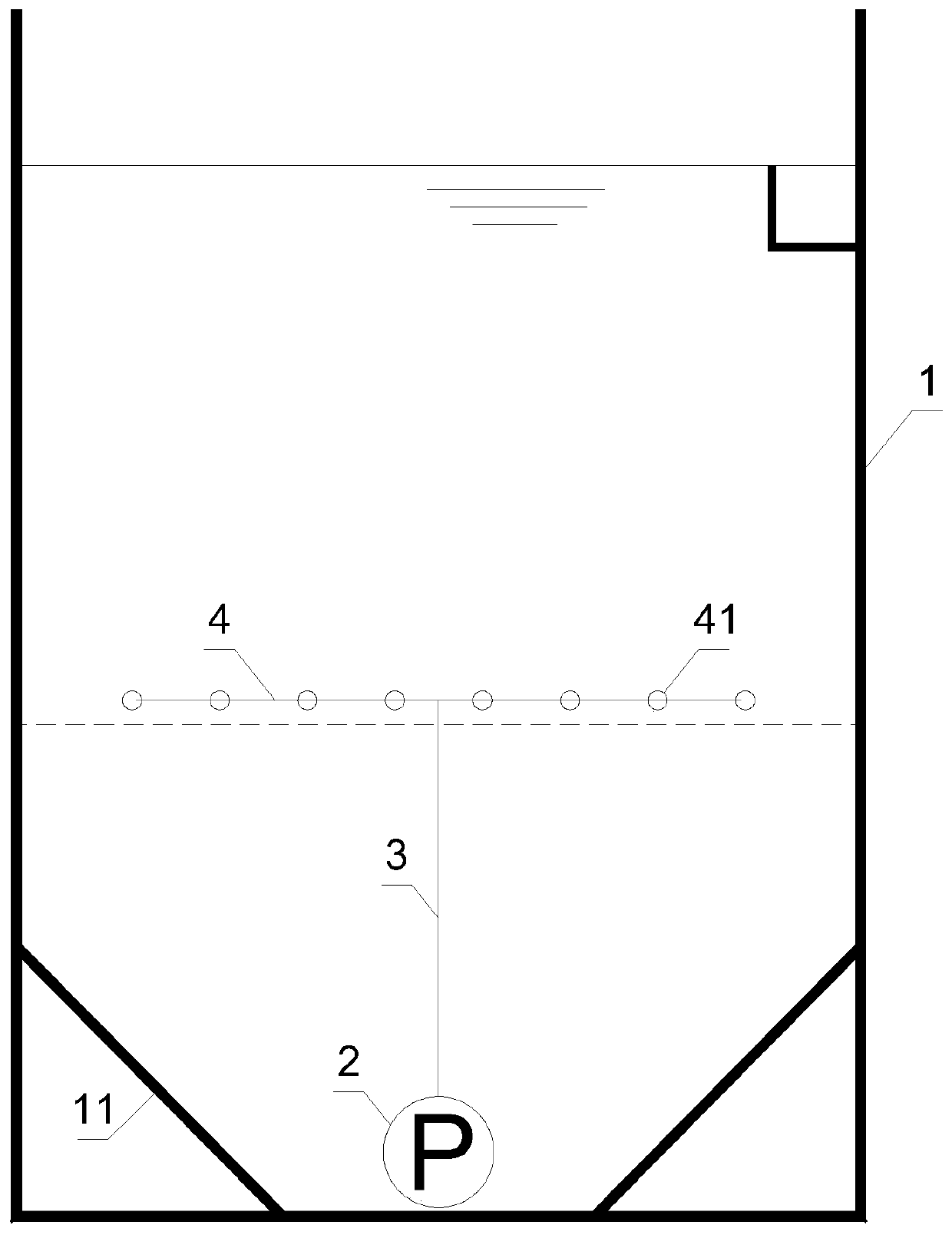

[0029] (1) Apply this process structure in the sedimentation tank 1 of the small-scale sewage treatment equipment, arrange the annular sewage pipe 4 at 30 cm above the sedimentation tank 1 mud bucket 11, drill a drainage hole 41 every 2 cm on the annular sewage pipe 4, use The sewage pump 2 discharges the sludge through the drainage hole 41 after being extracted;

[0030] (2) After the operation of the process equipment, the sludge floating phenomenon is improved, and the water quality of the equipment effluent is improved;

[0031] (3) Add a time relay to make the sewage pump 2 run intermittently, and further investigate the influence of stirring time on the sludge floating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com