Industrial boiler flue gas desulfurization and denitrification equipment

A desulfurization and denitrification, industrial boiler technology, applied in gas treatment, combined device, membrane technology and other directions, can solve the problems of acid rain, increase in the total amount of water vapor, white smoke, etc., achieve good desulfurization and denitrification effect, extend the circulation path, improve The effect of the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

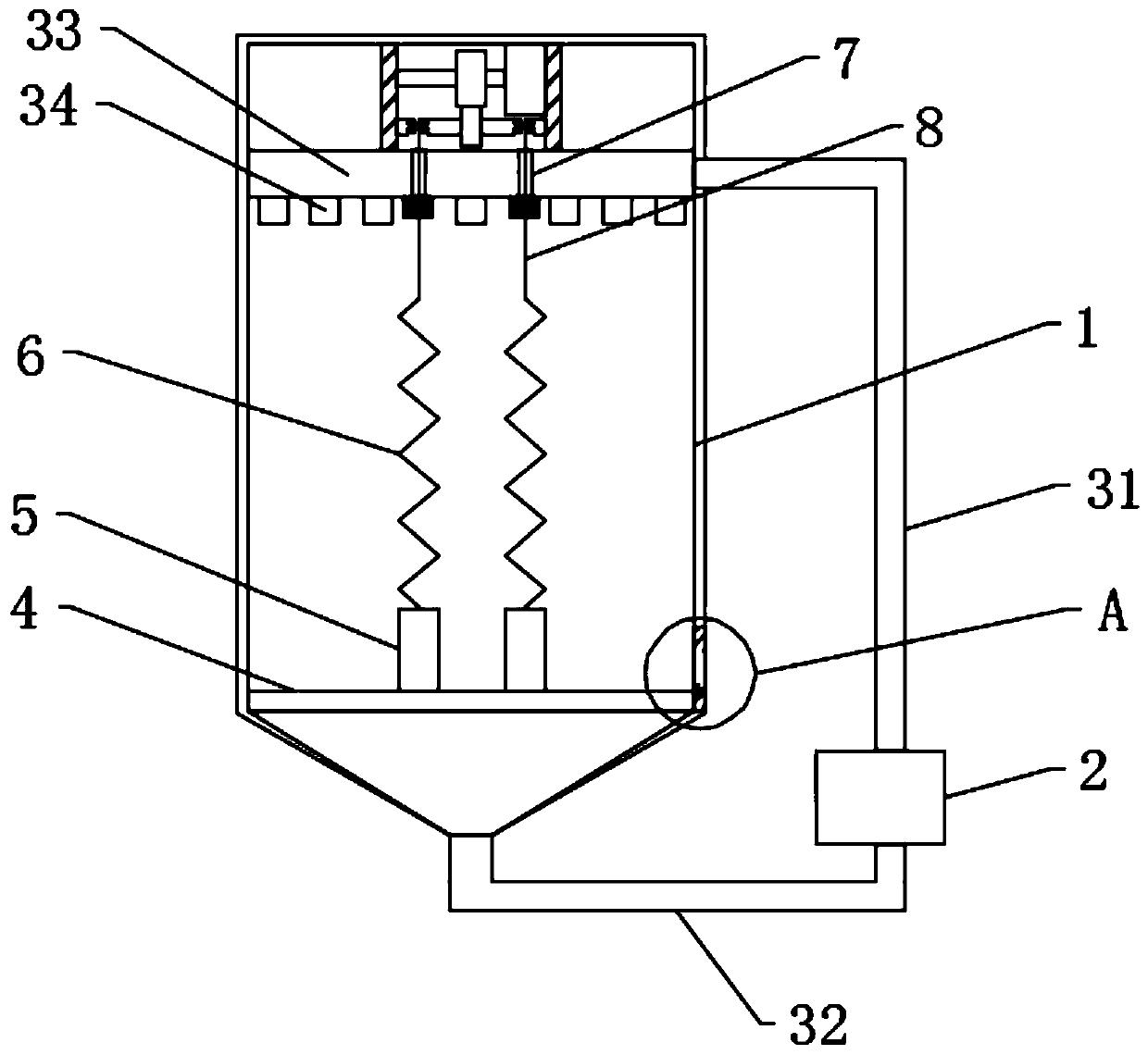

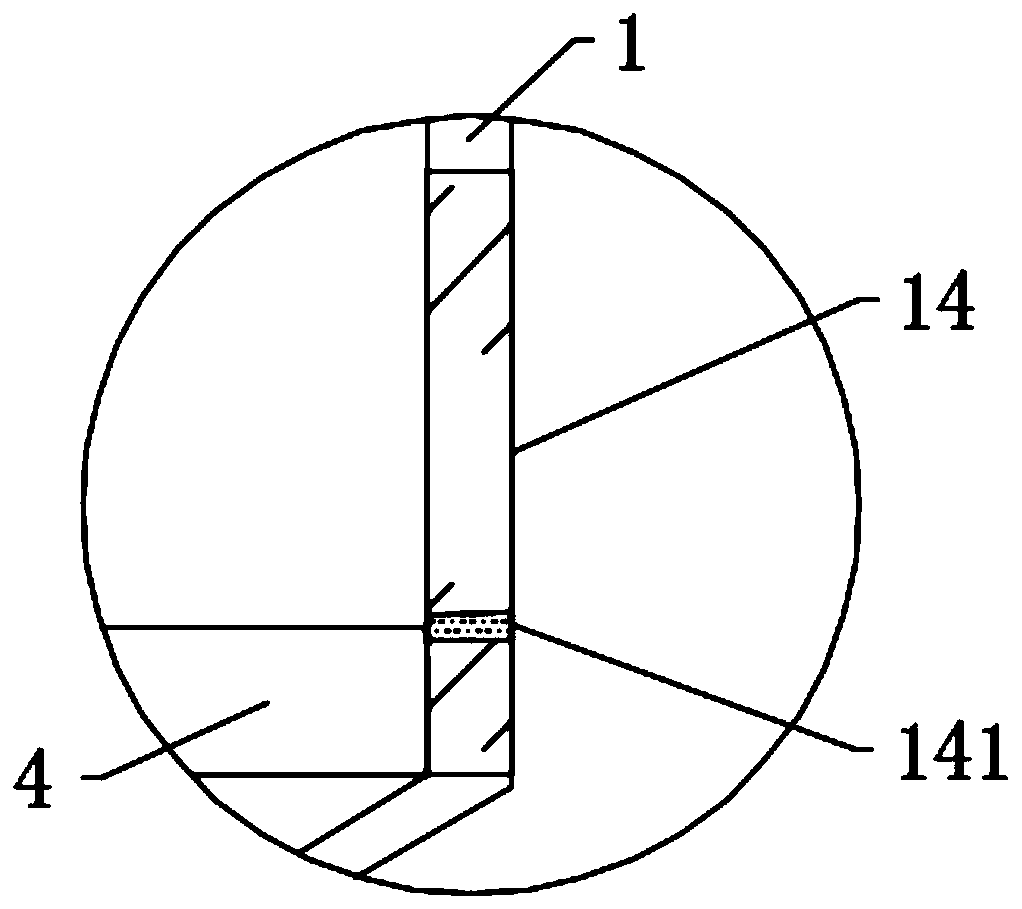

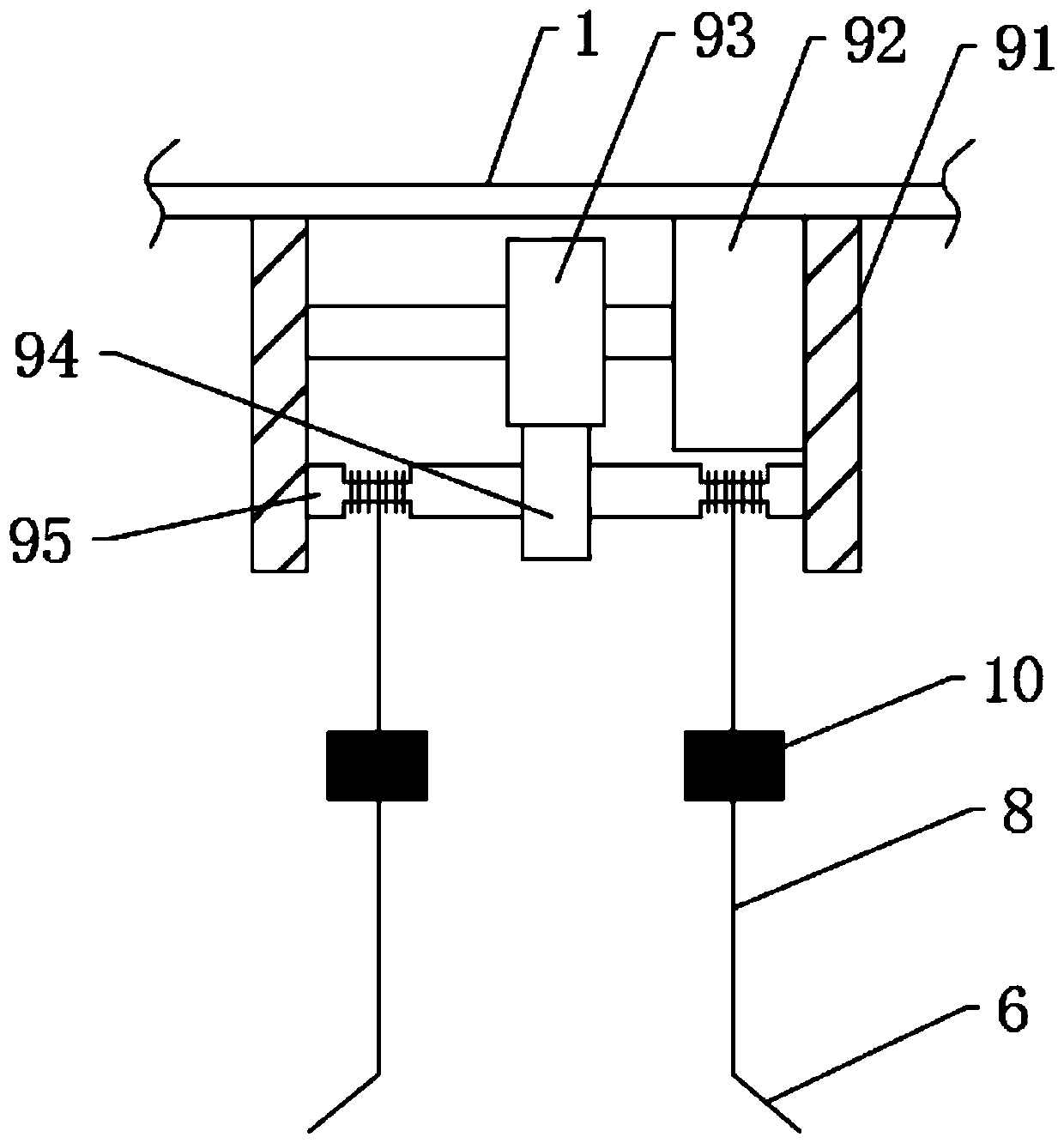

[0039] see figure 1 , an industrial boiler flue gas desulfurization and denitrification equipment, comprising a main body 1, a liquid pump 2 is arranged on the outside of the main body 1, an upper pipe 31 and a lower pipe 32 are fixedly connected to the upper and lower ends of the liquid pump 2 respectively, and the upper pipe 31 The upper end runs through the side wall of the equipment main body 1 and is fixedly connected with the main spray box 33, and the lower end of the main spray box 33 is fixedly connected with a plurality of uniformly distributed nozzles 34, and the end of the lower pipe 32 away from the liquid pump 2 is connected to the bottom of the equipment main body 1. The lower end is fixedly connected, the inner end of the equipment main body 1 is fixedly connected with a support rod 4, and the support rod 4 is located on the lower side of the main spray box 33, and the upper end of the support rod 4 is fixedly connected with a pair of positioning blocks 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com