New energy automobile transmission intermediate shaft production technology

A technology for new energy vehicles and production processes, applied in the field of automobile transmissions, can solve the problems of difficulty in meeting the quality requirements of new energy vehicle parts, poor compactness, easy fracture and damage, etc., and achieves dense grain structure and mechanical properties. High, short production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

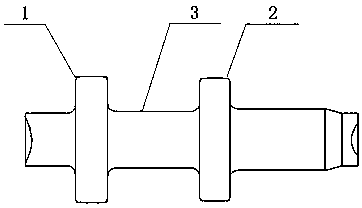

[0016] Example: see figure 1 As shown, a new energy vehicle transmission intermediate shaft blank includes a rod part and a cam provided on it, and the rod part is sequentially provided with a second cam 1 and a first cam 2 for subsequent processing into gears from left to right, Between the second cam 1 and the first cam 2 is an intermediate shaft portion 3 .

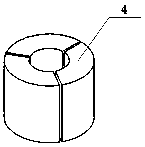

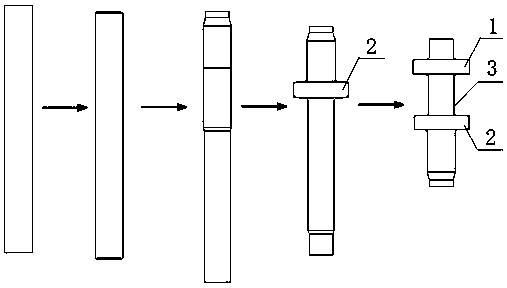

[0017] see figure 2 with image 3 As shown, the production process of the intermediate shaft of the new energy vehicle transmission includes the following steps: ① blanking: cutting the required metal bar; Annealing treatment, spheroidization rate ≥ 90%, surface hardness ≤ 80HRC; ③ Billet shot blasting phosphorus saponification: remove surface defects, sand blasting, lubrication treatment; ④ Reduced diameter extrusion: reduce diameter cold extrusion of the above bar through the mold ; ⑤ Upsetting cold extrusion: Upsetting and cold extrusion of the above bar through the mold, so that the first cam is formed on the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com